Fast plug-type buckle connected solenoid valve

A solenoid valve and snap-fit technology, which is applied in the field of solenoid valves, can solve problems such as solenoid valve leakage, shedding failure, water seepage, etc., and achieve the effects of improving assembly efficiency, improving reliability, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

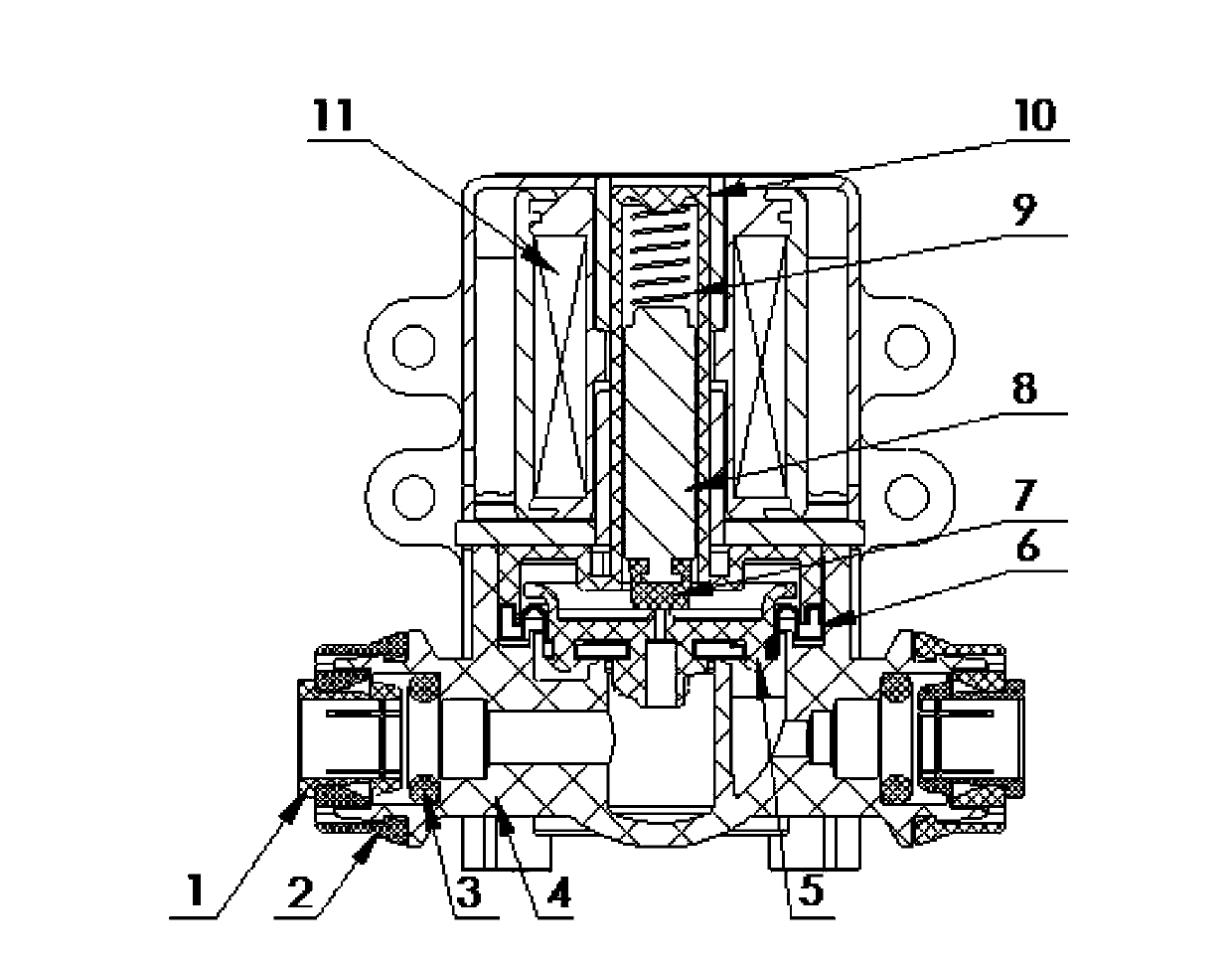

[0020] Such as figure 1 As shown, a solenoid valve with fast plug-in buckle connection includes a valve body 4 and a buckle 1, the valve body 4 is an axisymmetric structure, and the buckle 1 is connected to both ends of the valve body 4, so The valve body 4 described above is connected to the PE pipe through a buckle 1. The valve body 4 is provided with a diaphragm 6, a moving iron core 8, a spring 9, a coil part 11 and a valve cover 10, and one end of the moving iron core 8 is provided with a seal 7 , The diaphragm 6 is set on the diaphragm support 5 . The solenoid valve also includes an O-ring 3 and a compression cover 2, the compression cover 2 is arranged on the buckle 1, and is snap-connected with the valve body 4, and the O-ring 3 is arranged on the buckle 1 and valve body 4. The solenoid valve uses the elasticity of the compression cover 3 to permanently press the compression cover into the valve body 4, fix the buckle 1, use the buckle 1 to grasp the PE pipe, and use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com