Cross linear distributed fuel gas manifold

A linear arrangement, cross-shaped technology, applied in the direction of branch pipelines, pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of difficult welding processing, easy to appear virtual welding, and reduce the intake area, so as to achieve sealing performance and Good connection strength, improved sealing welding performance, and optimized welding process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

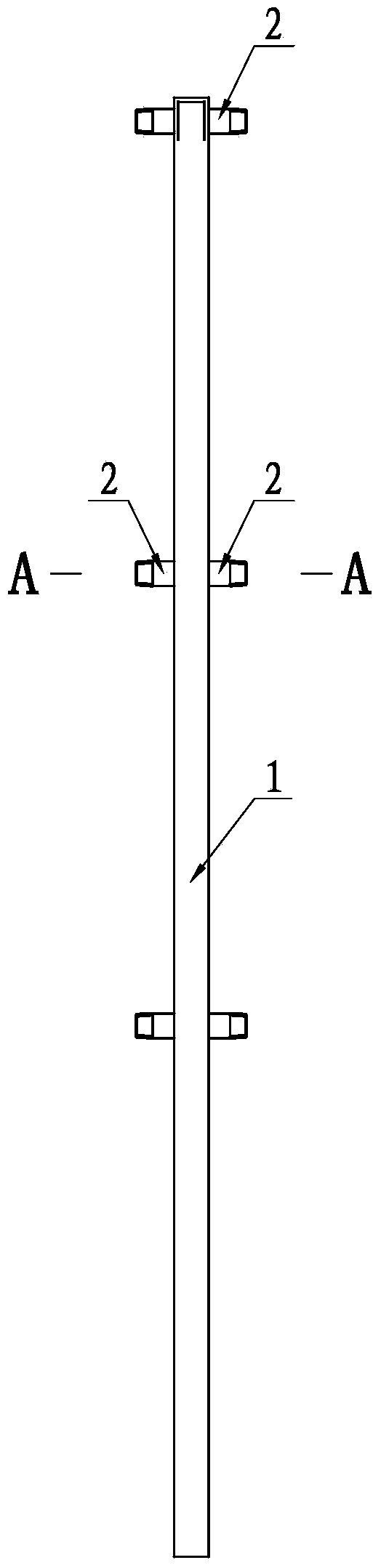

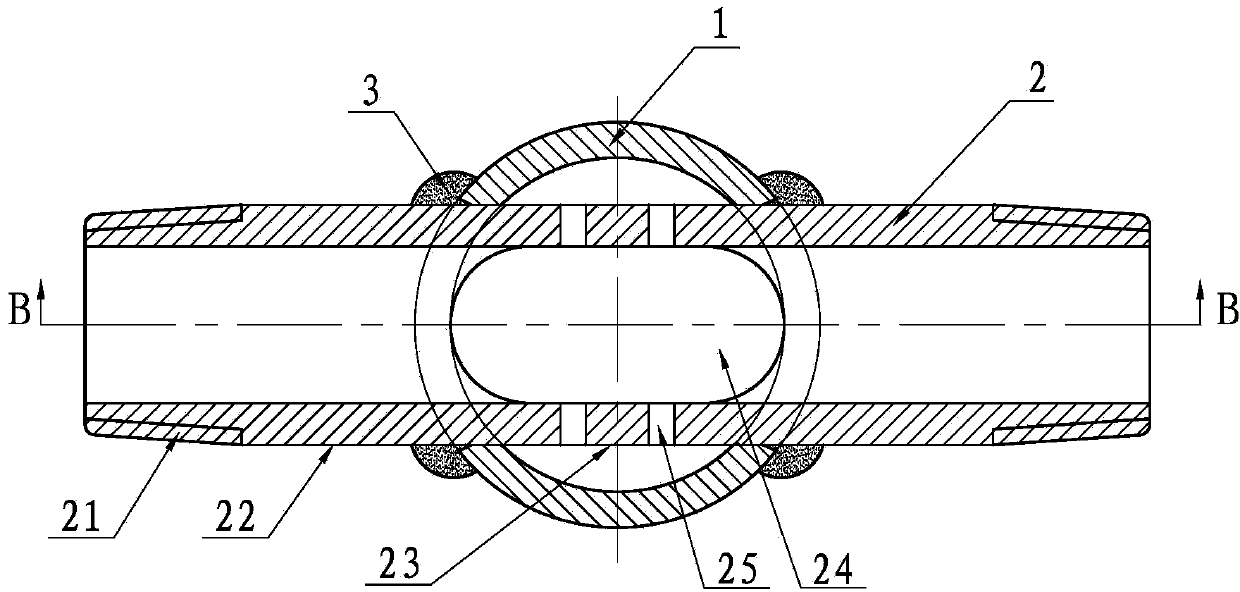

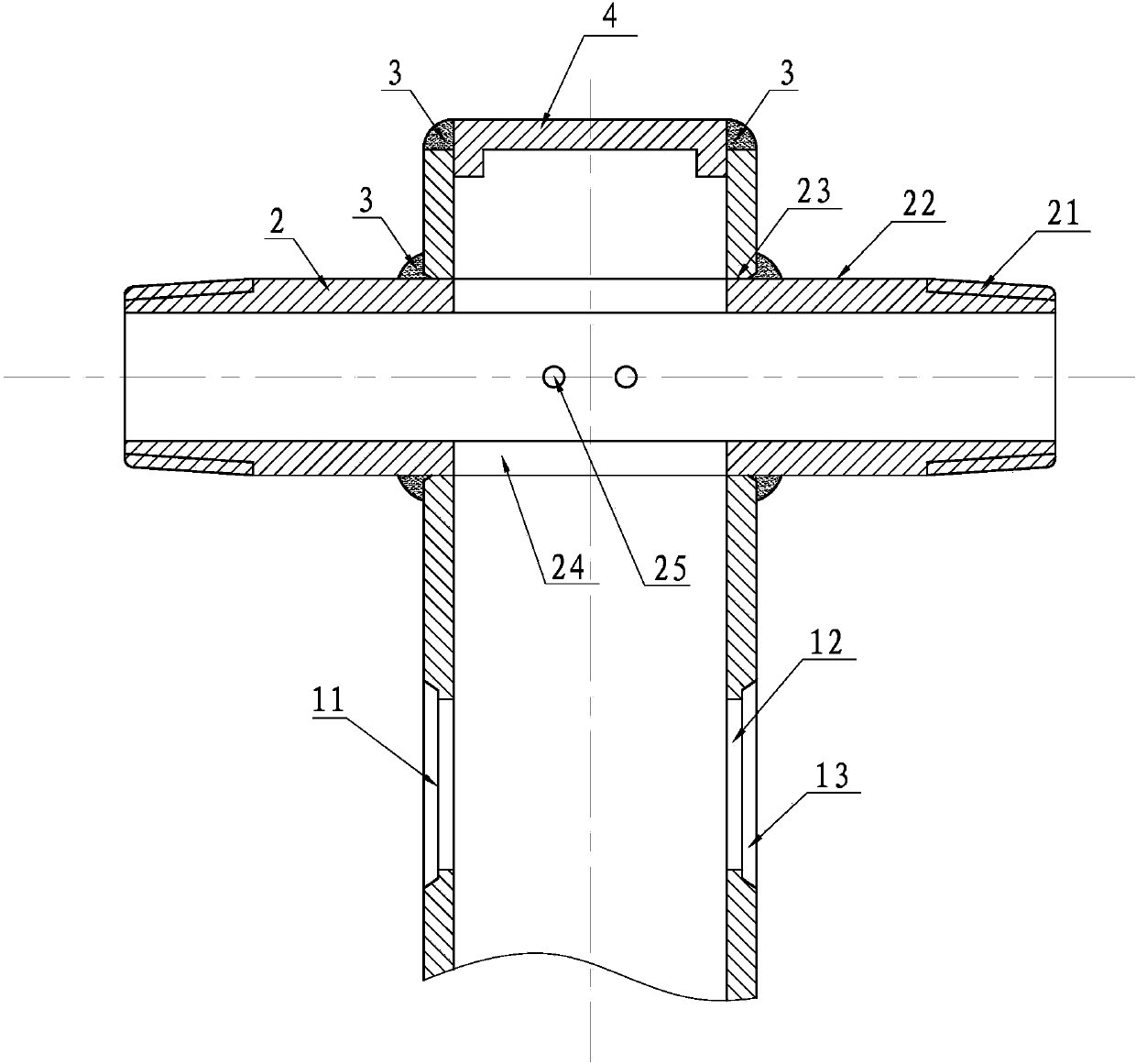

[0022] A cross-shaped gas manifold arranged in a straight line, including an air inlet pipe 1 and a threaded pipe joint 2, on the air inlet pipe 1, coaxial hole systems 11 are arranged at intervals in the axial direction, and the axes of all the coaxial hole systems 11 are at the same In the plane, and the axis of the coaxial hole system 11 is perpendicular to the axis of the intake pipe 1, the coaxial hole system 11 is a through-hole structure, and the threaded pipe joint 2 is a double-head structure, which consists of a connecting thread section 21, a transition section 22 and a matching The connecting threaded section 21 is arranged at both ends of the threaded pipe joint 2 for connecting and installing the gas meter. The mating section 23 is located in the middle of the threaded pipe joint 2. The diameters of the transition section 22 and the mating section 23 are the same and are larger than the connecting section 22. The maximum outer diameter of the threaded section 21 i...

Embodiment 2

[0023] Embodiment 2: The coaxial hole system 11 is composed of a positioning matching hole 12 and a welding groove hole 13, the welding groove hole 13 is arranged outside the positioning matching hole 12, and the welding seam 3 is simultaneously connected with the welding groove hole 13 1. The outer pipe wall of the intake pipe 1 is sealed and fixedly connected with the outer circular surface of the transition section 22 of the threaded pipe joint 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com