A device that can detect the motion state of the ball in the rolling kinematic pair

A technology of balls in the motion state and pair, which is applied in the direction of measuring/indicating equipment, machine gear/transmission mechanism testing, metal processing machinery parts, etc., can solve the problem of loss of pre-tightening force, degradation of rolling motion pair precision, and inability to directly observe the ball Running status and other issues, to achieve the effect of simple structure and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

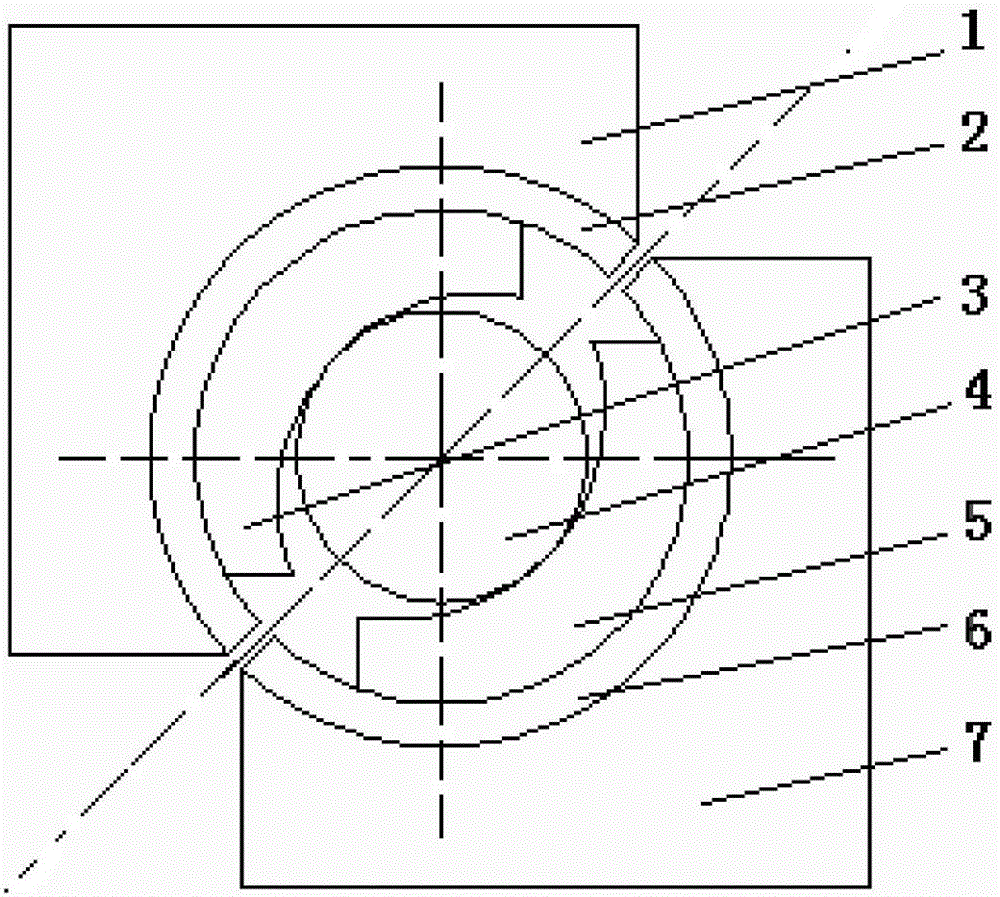

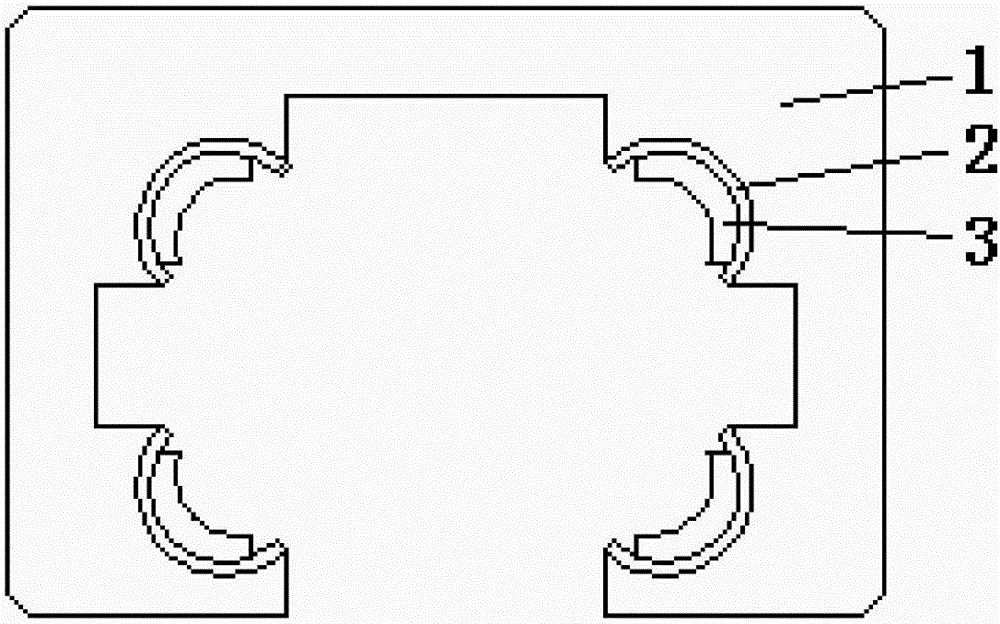

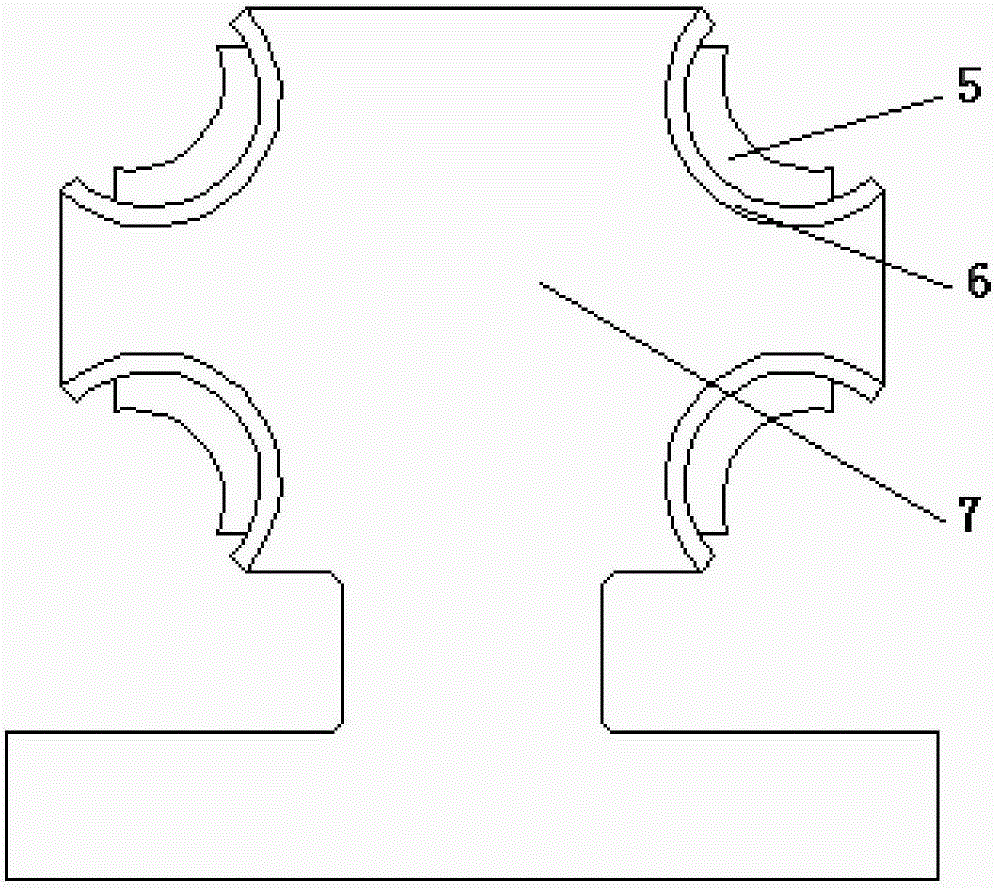

[0021] Such as Figure 1-8 As shown, a device that can detect the motion state of the ball in the rolling motion pair, the device includes a slider 1, a slider magnetic switch ring 2, a non-metallic slider raceway 3, a magnetic ball 4, a non-metallic guide rail raceway 5 , guide rail magnetic switch ring 6, guide rail 7, magnetic switch array 8, ball strong magnet 9.

[0022] Slider 1, slider magnetic switch ring 2, non-metallic slider raceway 3, the three are fixedly connected by keys or pins, and there is no relative movement between the three; non-metallic guide rail raceway 5, guide rail magnetic switch ring 6. The guide rail 7 is also connected and fixed by keys or pins, and there is no relative movement between the three; the slider 1 and the guide rail 7 cooperate to form a rolling motion pair. In the rolling motion pair, the slider 1 passes The ball moves linearly along the guide rail 7; the magnetic ball 4 and other balls roll between the non-metal slider raceway 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com