A harvester rotates a large granary

A harvester and granary technology, applied in harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of inconvenient logistics and transportation, large deformation of columns, and low maintenance efficiency, and achieve easy transportation and disassembly, small deformation, and strength. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

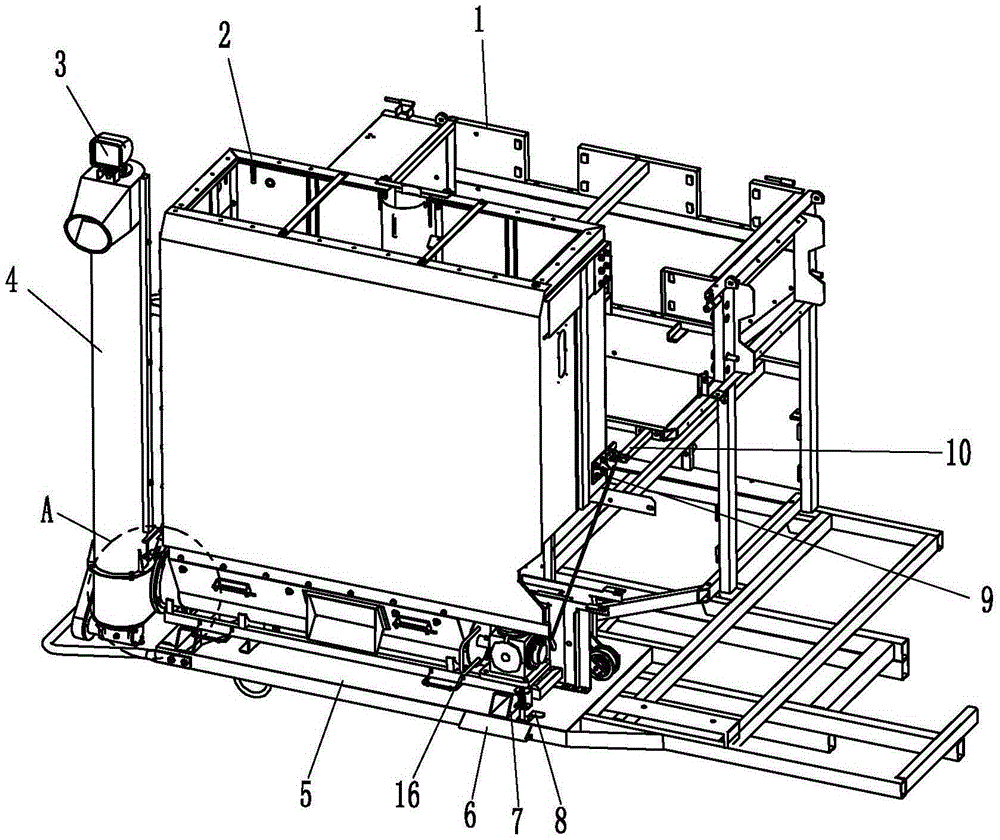

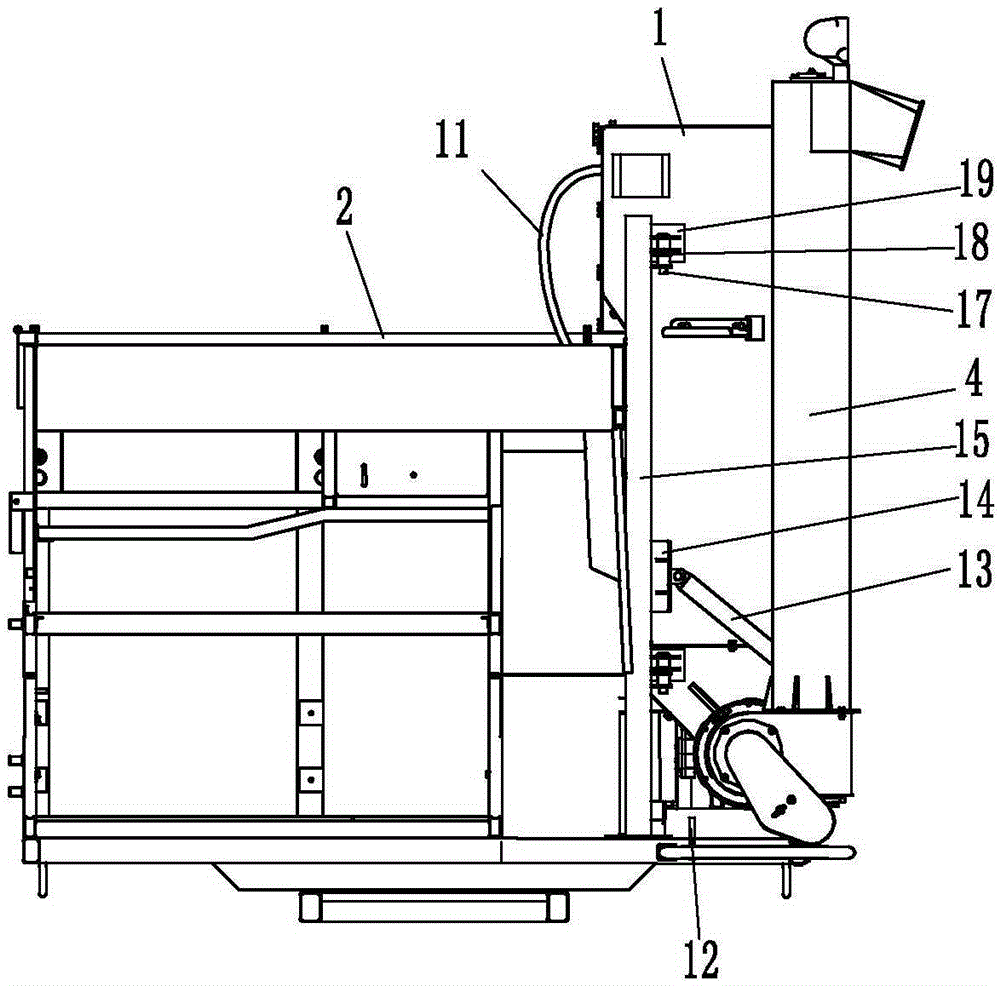

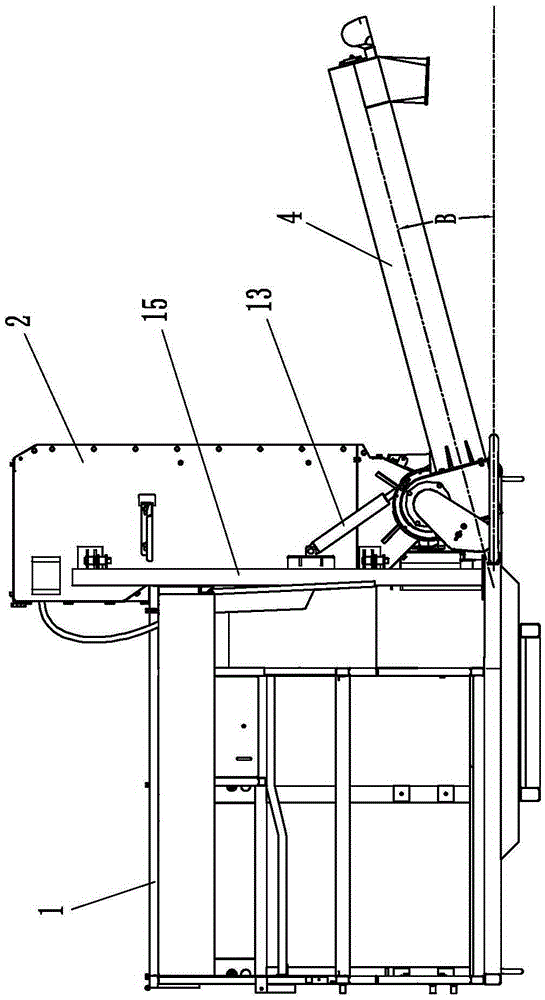

[0028] Such as Figure 1 to Figure 9 As shown, the harvester of the present invention rotates a large granary, and the rotary large granary includes a non-rotating device and a rotating device.

[0029] The non-rotating device includes a column welding 15, a granary transfer-in limiter, and a granary transfer-out limiter. Described column welding 15 comprises column 31, the bottom fara plate 32 that is connected at the bottom of column 31, the column hinge seat 18 that is connected at one side of column 31, as Image 6 As shown, in the present embodiment, there are two column hinge seats 18, the number of column hinge seats 18 can be set in different quantities according to the size of the harvester, and the upper side of the column welding 15 is fixedly connected to the harvester thresher by bolts After the afterbody of cleaning frame 1, the bottom flange plate 32 of column welding 15 lower ends is fastened and connected on the harvester chassis 5 with bolts. The granary is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com