Full-automatic flame cutting device

A flame cutting and cutting device technology, applied in auxiliary devices, gas flame welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high labor cost, high labor intensity, low efficiency, etc., and achieve low cost and high work efficiency. , the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

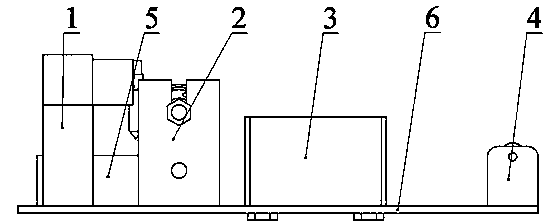

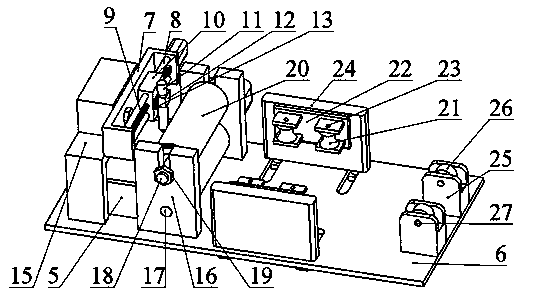

[0026] Example 1: Such as figure 1 , figure 2 , Figure 5 , Figure 8 , a fully automatic flame cutting device, the fully automatic flame cutting device includes a cutting device 1, a longitudinal pressing device 2, a lateral limiting device 3, a support wheel device 4, a finished product collection box 5 and a device bottom plate 6, the described The cutting device 1 is installed on one end of the device base plate 6 by welding, and the longitudinal pressing device 2 is installed on the device base plate 6 by welding, and a finished product collection box 5 is arranged between the cutting device 1 and the longitudinal pressing device 2, so that The lateral limiting device 3 is installed on the bottom plate 6 of the device through a limit adjusting screw 35, and the supporting wheel device is installed on the other end of the bottom plate of the device. In this technical solution, the cutting device 1 is used for flame cutting the plate 38, the longitudinal pressing devi...

Embodiment 2

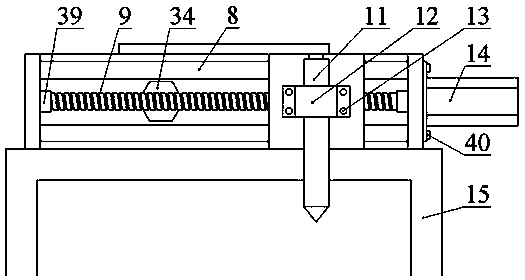

[0027] Example 2: Such as figure 1 , figure 2 , image 3 , Figure 5, as an improvement of the present invention, the cutting device 1 includes a cutting device mounting frame 7, a cutting device support frame 15, a sliding rod 8, a lead screw 9, a sliding block 10, a linkage device 39, a small servo motor 14, a small servo Motor screw 40 and screw rod 34, described cutting device support frame 15 is installed on the front end position of device bottom plate by welding, and described cutting device mounting frame 7 is installed on the cutting device support frame 15 by screw rod 34, and described slide bar 8 is threaded Installed on the cutting device mounting frame, one end of the leading screw 9 is installed on the cutting device mounting frame through a linkage 39, and the other end is connected to a small servo motor 14, and the small servo motor 14 is installed on the cutting device through a small servo motor screw 40. The right end of the mounting frame 7, the sli...

Embodiment 3

[0028] Example 3: Such as figure 1 , image 3 , as an improvement of the present invention, the linkage device 39 is set as a rolling bearing or other bearing structure. The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com