Rear longitudinal cutting mechanism of bag making machine

A bag making machine and slitting technology, which is applied to container manufacturing machinery, paper/cardboard containers, containers, etc., can solve the problems of difficult adjustment of the position of the cutter, complicated installation process of the cutter, time-consuming and laborious, etc. Compact structure, avoid the effect of lifting and deviating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

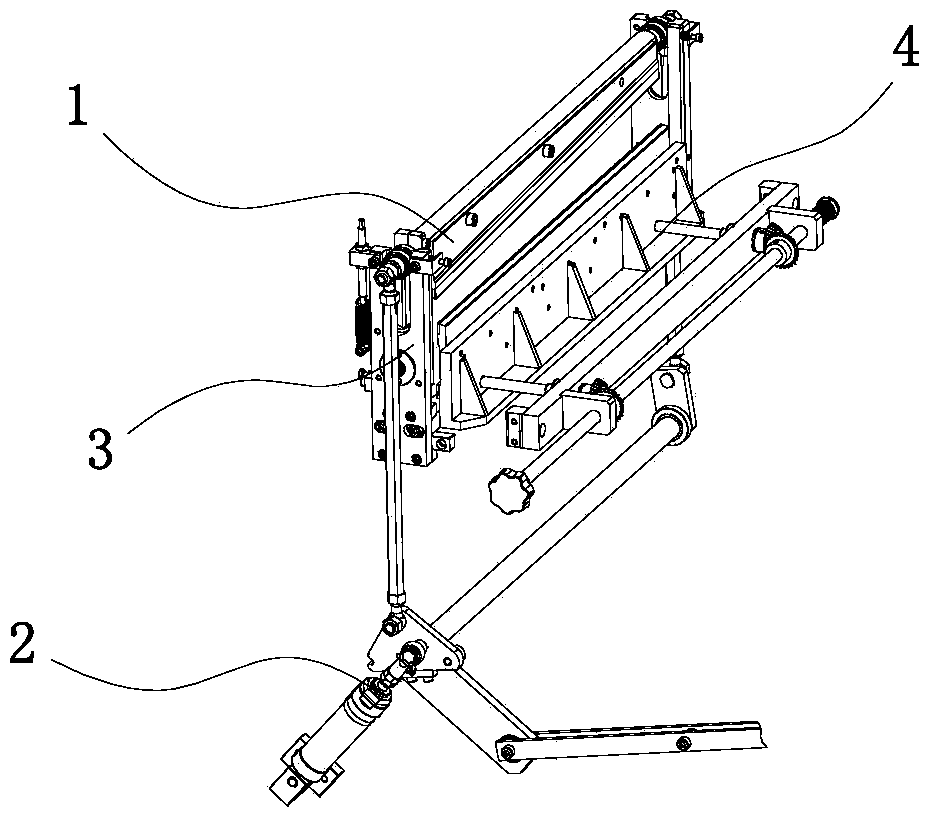

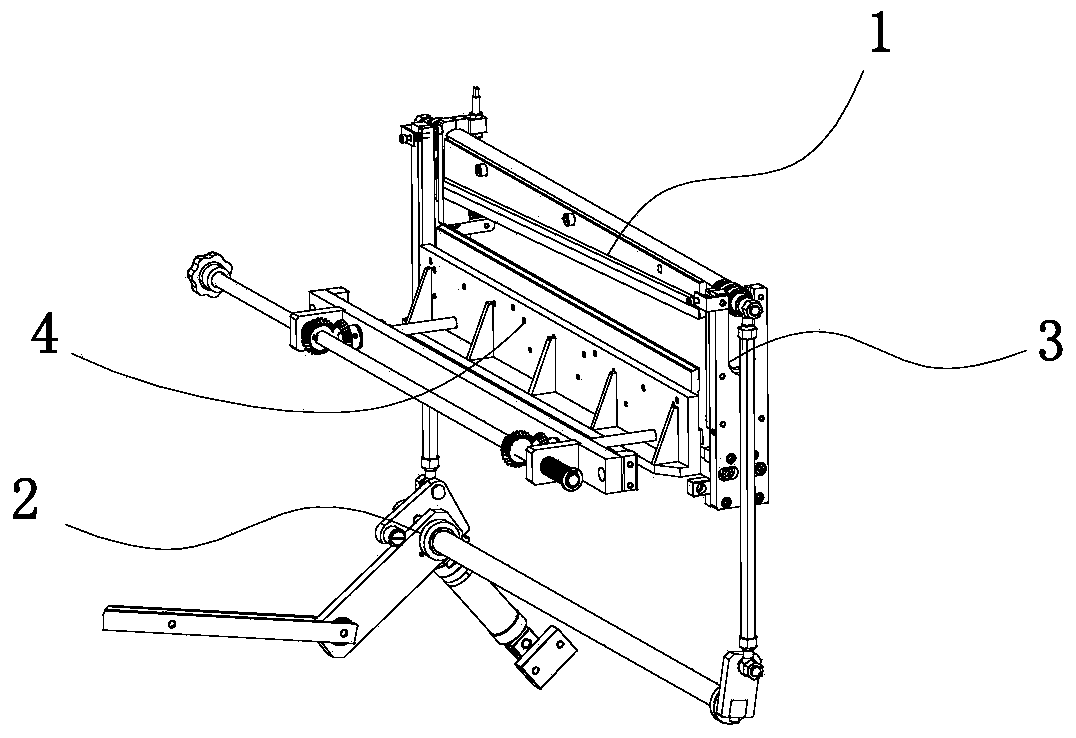

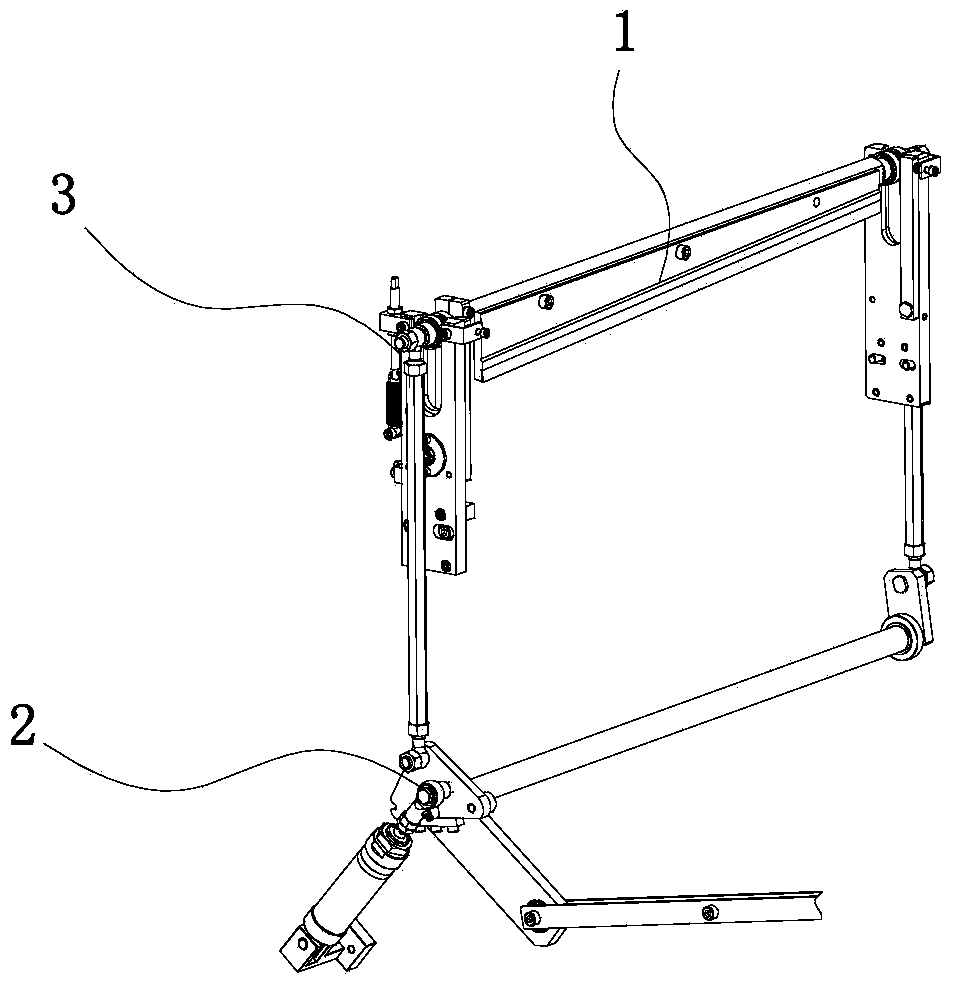

[0038] like Figure 1 to Figure 4 As shown, the rear slitting mechanism of the bag making machine of this embodiment includes an upper cutter frame 3 for installing the upper cutter 1 and an upper cutter pushing device 2 for driving the upper cutter 1 to move up and down;

[0039] like Figure 8 to Figure 14 As shown, the upper cutter frame 3 includes a lift bar 31 for the upper cutter 1 on the device, and the two ends of the lift bar 31 are slidingly installed on the two opposite frame plates 32, and the two ends of the lift bar 31 are respectively By means of the outer bearing 33 sliding device in the U-shaped groove 321 on the upper end of the frame plate 32, the two ends of the elevating cross bar 31 are also equipped with inner bearings 34 respectively, and the inner bearing 34 is positioned at the inner side of the outer bearing 33;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com