Glass structure for enhancing glass strength and manufacturing method thereof

A glass and strength technology, applied in chemical instruments and methods, glass/slag layered products, layered products, etc., to achieve the effect of not easily broken, improving shock resistance, pressure resistance and drop resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The invention will be described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the descriptions of the specific embodiments are only used to explain the technical solutions proposed by the present invention, not to limit the present invention.

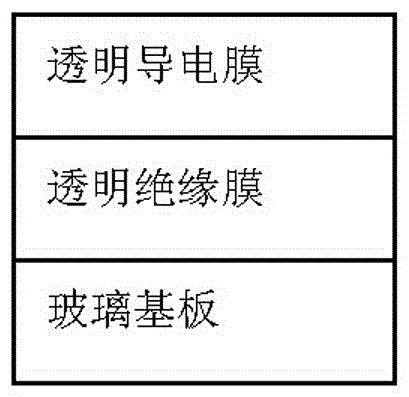

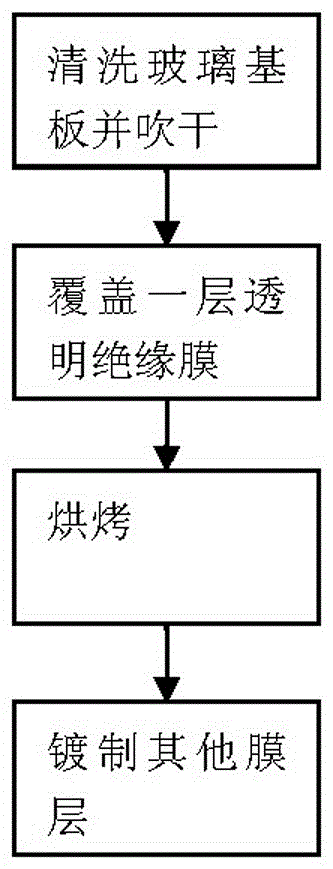

[0015] figure 1 It is a schematic diagram of the structure of an embodiment of the present invention. The glass structure to enhance the strength of glass proposed by the present invention is to cover a layer of transparent insulating film on the surface of the glass substrate by coating or printing. The transparent insulating film can use organic substances such as OC glue and PI glue, and the method of covering the transparent insulating film can be printing or coating. By covering the transparent insulating film, the strength of the glass can be improved. When the glass is subjected to the ball drop test, the height of the falling ball can be increased by 2-3 times...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com