Resin composition and molded body thereof

A technology of resin composition and compounding amount, which is applied in the field of resin composition containing polylactic acid, and can solve the problems of plasticizer leakage and low plasticizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] Hereinafter, although an Example is shown and this invention is demonstrated in more detail, this invention is not limited to these Examples.

[0052] (raw material)

[0053] Copolyester raw material A: P(LA-co-3HB) manufactured according to the description of the literature: Journal of Biotechnology, 154 (2011), pp. 255-260 was obtained from Tokyo University of Agriculture and used. The mole fraction of lactic acid constituting the copolyester raw material A was 45 mol%, and the weight average molecular weight was about 110,000. The measurement of the mole fraction and weight average molecular weight of these lactic acids is based on the measurement method described in the said document. In addition, the monomer unit derived from lactic acid in this copolyester raw material A is a monomer unit derived from D-lactic acid.

[0054] Copolyester raw material B for comparison: A copolymer of 3-hydroxybutyric acid and 3-hydroxyhexanoic acid: P(3HB-co-3HH) produced accordin...

Embodiment 2

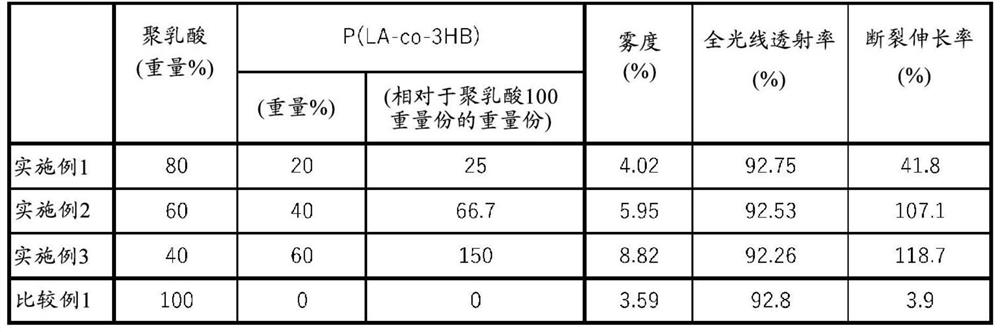

[0065] The weight ratio of the polylactic acid raw material A and the copolyester raw material A was changed to 60:40 (66.7 parts by weight of the copolyester relative to 100 parts by weight of polylactic acid), and obtained by the same method as in Example 1 except that Granules and tablets were measured for haze, total light transmittance and elongation at break. These results are shown in Table 1.

Embodiment 3

[0067] The weight ratio of polylactic acid raw material A and copolyester raw material A was changed to 40:60 (150 parts by weight of copolyester relative to 100 parts by weight of polylactic acid), and obtained by the same method as in Example 1 except that Granules and tablets were measured for haze, total light transmittance and elongation at break. These results are shown in Table 1.

[0068]

[0069] Except for using only the polylactic acid raw material A instead of the copolyester raw material A, pellets and sheets were obtained in the same manner as in Example 1, and the haze, total light transmittance, and elongation at break were measured. These results are shown in Table 1.

[0070] [Table 1]

[0071]

[0072] From Table 1, it is clear that the haze of polylactic acid does not substantially increase by compounding P(LA-co-3HB) to polylactic acid, but the elongation at break increases significantly. From this, it can be seen that the complexation with P(LA-co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| haze | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com