Mirror explosion-proof film

A technology of explosion-proof film and mirror surface layer, which is applied in the direction of film/sheet-like adhesives and adhesives, can solve the problems of insufficient UV protection, inability to match, affecting wireless signals, etc. good mirror effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

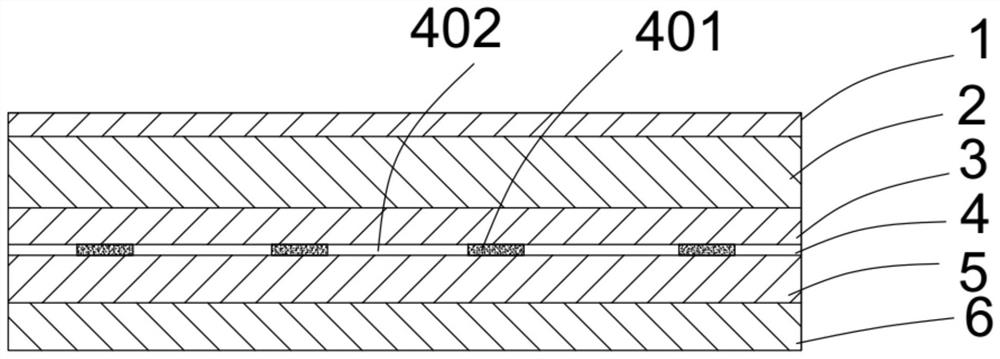

[0025] Such as figure 1 As shown, a mirror explosion-proof film, the mirror explosion-proof film comprises from top to bottom: a protective layer 1, a main film layer 2, a mirror layer 3, a grating layer 4, a pressure-sensitive adhesive layer 5 and a release film layer 6;

[0026] The mirror layer 3 is coated with mirror ink, and the mirror ink includes: 30% acrylic resin, 30% methyl ethyl ketone, 20% butyl acetate, 0.2% dispersant, 0.3% heat stabilizer, and 5% silica sol , flaky glass powder 5.5%, polyisocyanate 9%; among them, the dispersant model BYK-P104S used, BYK of Germany; the heat stabilizer used is BASF Tinuvin622LD; the silica sol used is ethanol silica sol ND-0104, and the silica content 30%, Suzhou Nadi Microelectronics;

[0027] Silica sol and scaly glass powder play an important role in the formation of the mirror effect. It is worth noting that the mirror effect of the mirror layer of the present invention is compared with the metal mirror layer made by magnet...

Embodiment 2

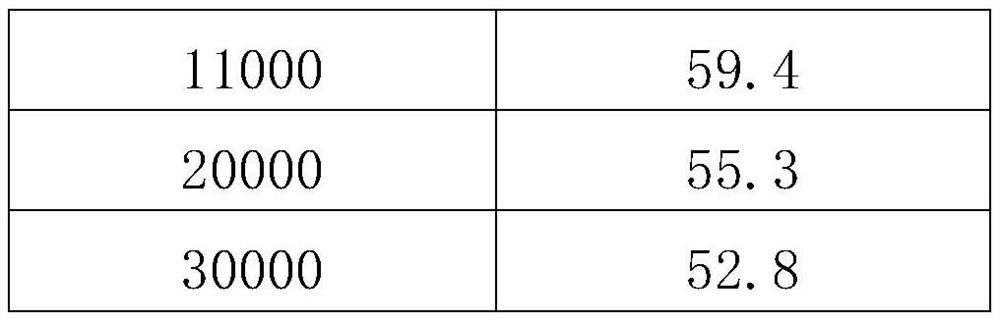

[0041] Using the PEAKMETER brand PM6612L digital illuminance meter, respectively test the light transmittance of the mirror explosion-proof film of Example 1 under different direct light intensity, the obtained data are as follows:

[0042]

[0043]

[0044] It can be known from the above data that the light transmittance of the explosion-proof mirror film of Example 1 will gradually decrease with the increase of light intensity, which has a good practical effect.

Embodiment 3

[0046] Install the wireless signal strength test software Homedale, version v1.71 on the notebook;

[0047] Respectively make a single-layer closed cylinder A and B made of the Wanxiang film mirror silver glass film and the mirror explosion-proof film of Example 1; put the A cylinder and the B cylinder opposite;

[0048] The measured wireless signal strength at a certain point outside is -62dbm; put the notebook into the A barrel and the B barrel respectively, and the measured wireless signal strength in the A barrel is -76dbm, and the wireless signal strength in the B barrel is -71dbm;

[0049] From the above data, it can be known that the mirror explosion-proof film of Example 1 has a better wireless signal transmittance than ordinary universal film brand mirror silver glass film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com