A kind of transparent flame-retardant antistatic polyamide film and preparation method thereof

A flame retardant and antistatic, polyamide film technology, applied in chemical instruments and methods, synthetic resin layered products, coatings, etc., can solve the problems of film transparency and mechanical properties decline, and achieve excellent antistatic performance, thermal conductivity Small, high transparency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

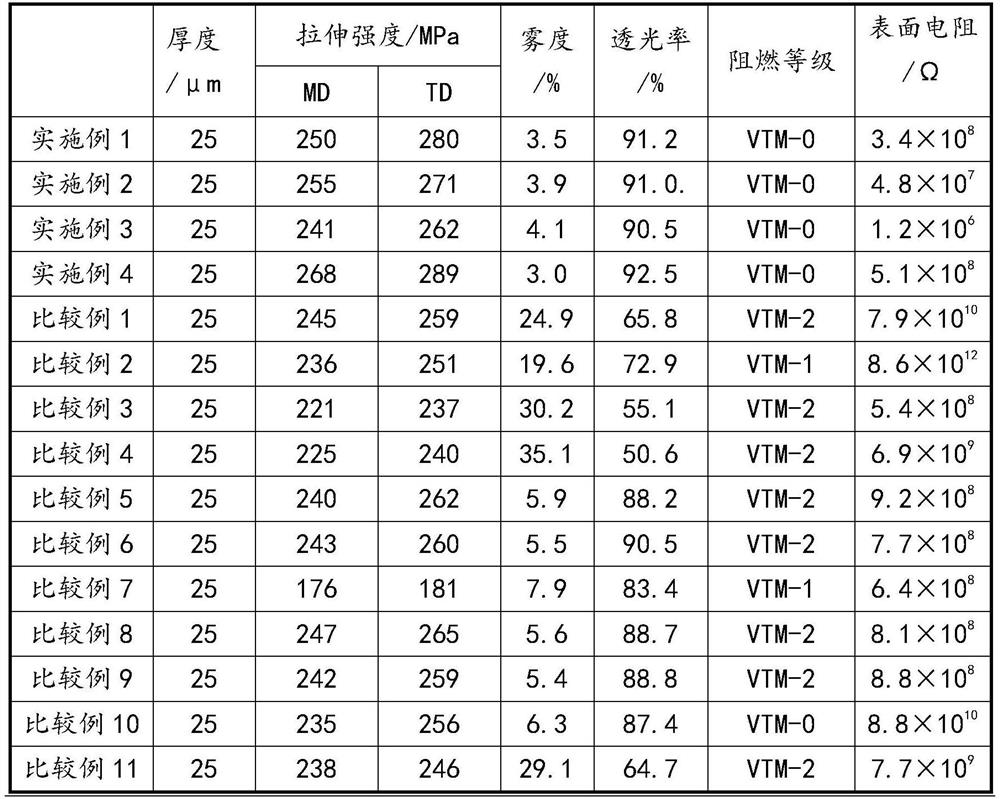

[0041] The transparent flame-retardant and antistatic polyamide film of this embodiment is a three-layer structure composed of a first surface layer, an intermediate layer and a second surface layer.

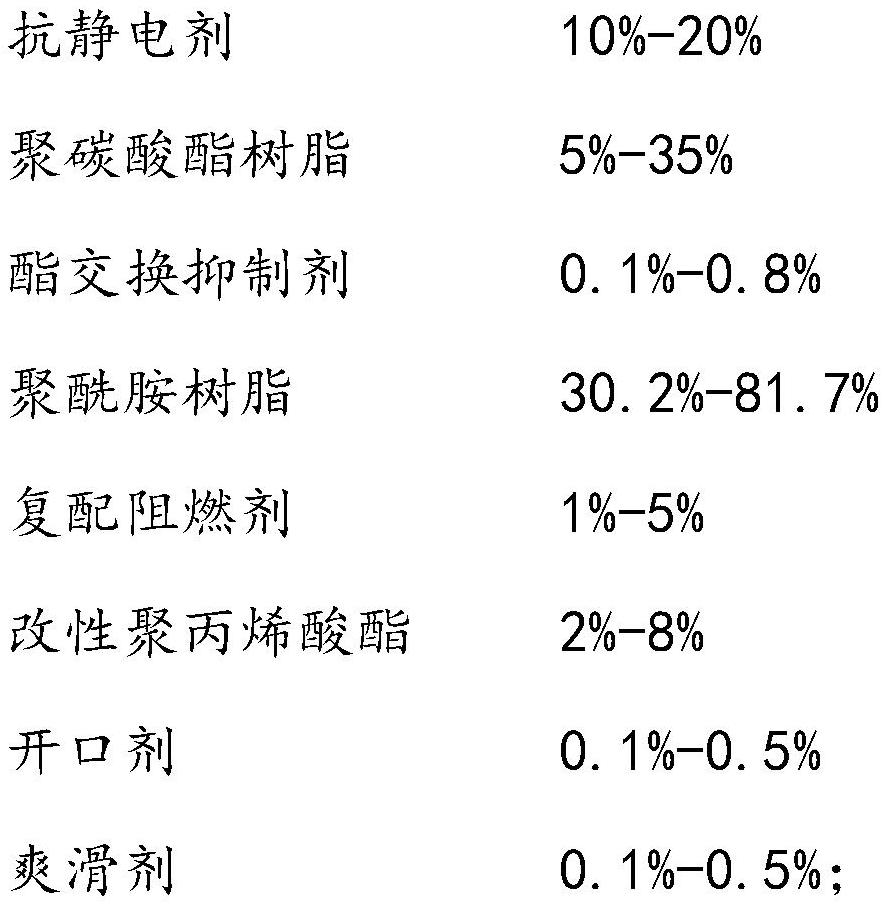

[0042] In terms of mass percentage, the first surface layer includes 10% antistatic agent, 20% polycarbonate resin, 0.5% transesterification inhibitor, 61% polyamide resin, 3% flame retardant, 5% modified Non-toxic polyacrylate, 0.25% anti-opening agent and 0.25% slip agent.

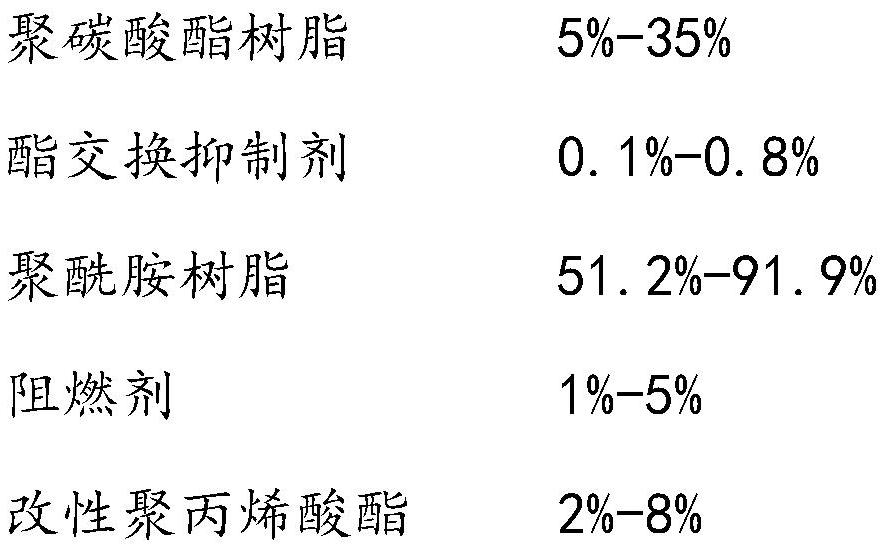

[0043] The second skin layer consists of 20% polycarbonate resin, 0.5% transesterification inhibitor, 71% polyamide resin, 3% flame retardant, 5% modified polyacrylate, 0.25% antiblocking agent and 0.25 % slip agent.

[0044]The middle layer is 20% polycarbonate resin, 0.5% transesterification inhibitor, 71.5% polyamide resin, 3% flame retardant, 5% modified polyacrylate.

[0045] The ratio of the compound flame retardant sulfonate, anti-dripping agent, organic silicon and hollow glass microspheres in th...

Embodiment 2

[0055] The transparent flame-retardant and antistatic polyamide film of this embodiment is a three-layer structure composed of a first surface layer, an intermediate layer and a second surface layer.

[0056] In terms of mass percentage, the first surface layer includes 15% antistatic agent, 20% polycarbonate resin, 0.5% transesterification inhibitor, 54% polyamide resin, 5% flame retardant, 5% modified Non-toxic polyacrylate, 0.25% anti-opening agent and 0.25% slip agent.

[0057] The second skin layer consists of 20% polycarbonate resin, 0.5% transesterification inhibitor, 69% polyamide resin, 5% flame retardant, 5% modified polyacrylate, 0.25% antiblocking agent and 0.25 % slip agent.

[0058] The middle layer is 20% polycarbonate resin, 0.5% transesterification inhibitor, 69.5% polyamide resin, 5% flame retardant, and 5% modified polyacrylate.

[0059] The ratio of the compound flame retardant sulfonate, anti-dripping agent, organic silicon and hollow glass microspheres ...

Embodiment 3

[0069] The transparent flame-retardant and antistatic polyamide film of this embodiment is a three-layer structure composed of a first surface layer, an intermediate layer and a second surface layer.

[0070] In terms of mass percentage, the first surface layer includes 20% antistatic agent, 20% polycarbonate resin, 0.5% transesterification inhibitor, 49% polyamide resin, 5% flame retardant, 5% modified Non-toxic polyacrylate, 0.25% anti-opening agent and 0.25% slip agent.

[0071] The second skin layer consists of 20% polycarbonate resin, 0.5% transesterification inhibitor, 69% polyamide resin, 5% flame retardant, 5% modified polyacrylate, 0.25% antiblocking agent and 0.25 % slip agent.

[0072] The middle layer is 20% polycarbonate resin, 0.5% transesterification inhibitor, 69.5% polyamide resin, 5% flame retardant, and 5% modified polyacrylate.

[0073] The ratio of the compound flame retardant sulfonate, anti-dripping agent, organic silicon and hollow glass microspheres ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com