Ink piece device

An ink piece and ink knife technology, applied in the field of ink piece devices, can solve the problems of difficult replacement of vulnerable parts, low ink use efficiency, and high printing cost, and achieve the effects of reducing ink consumption, facilitating replacement, and fast loading and unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

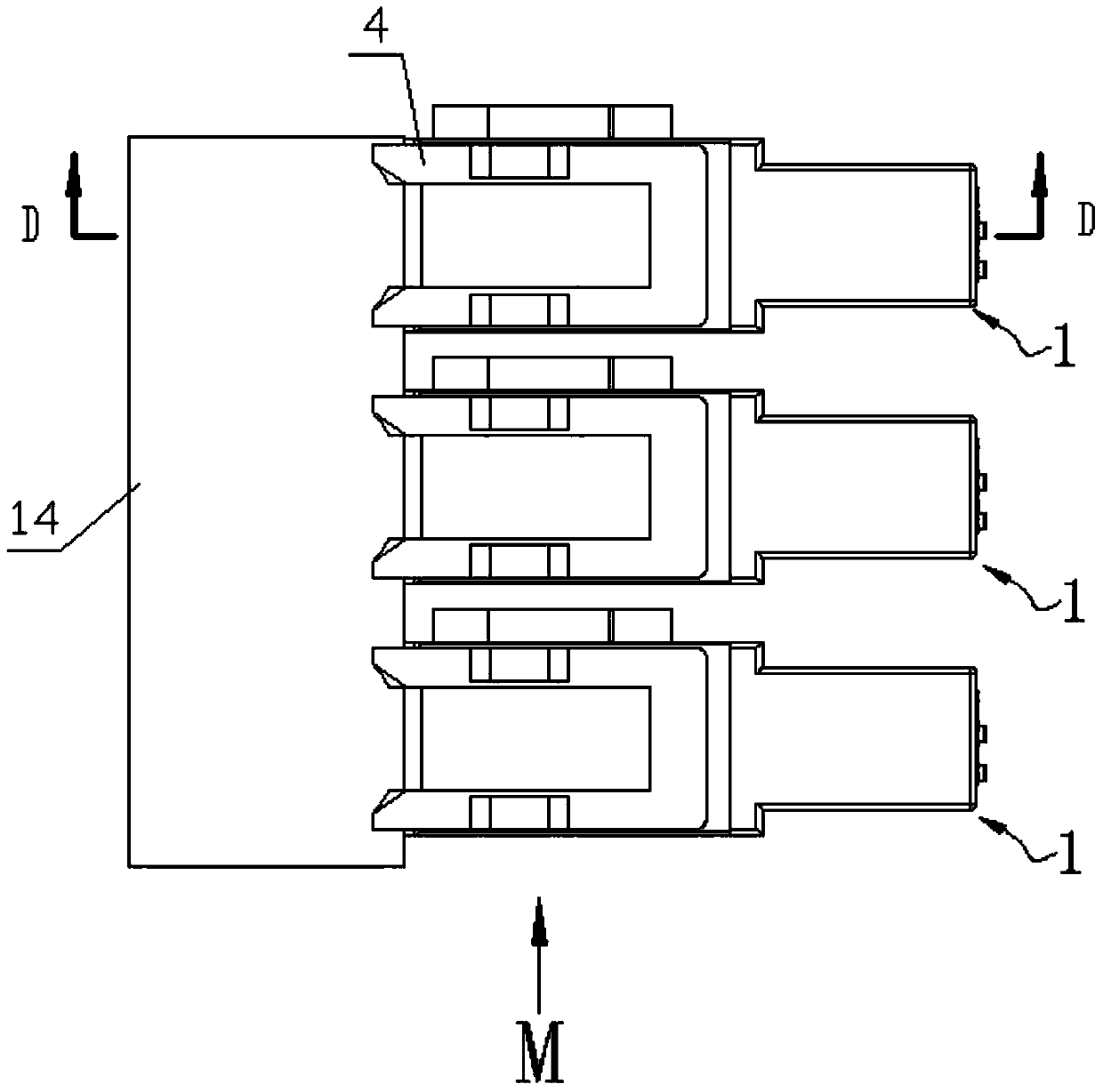

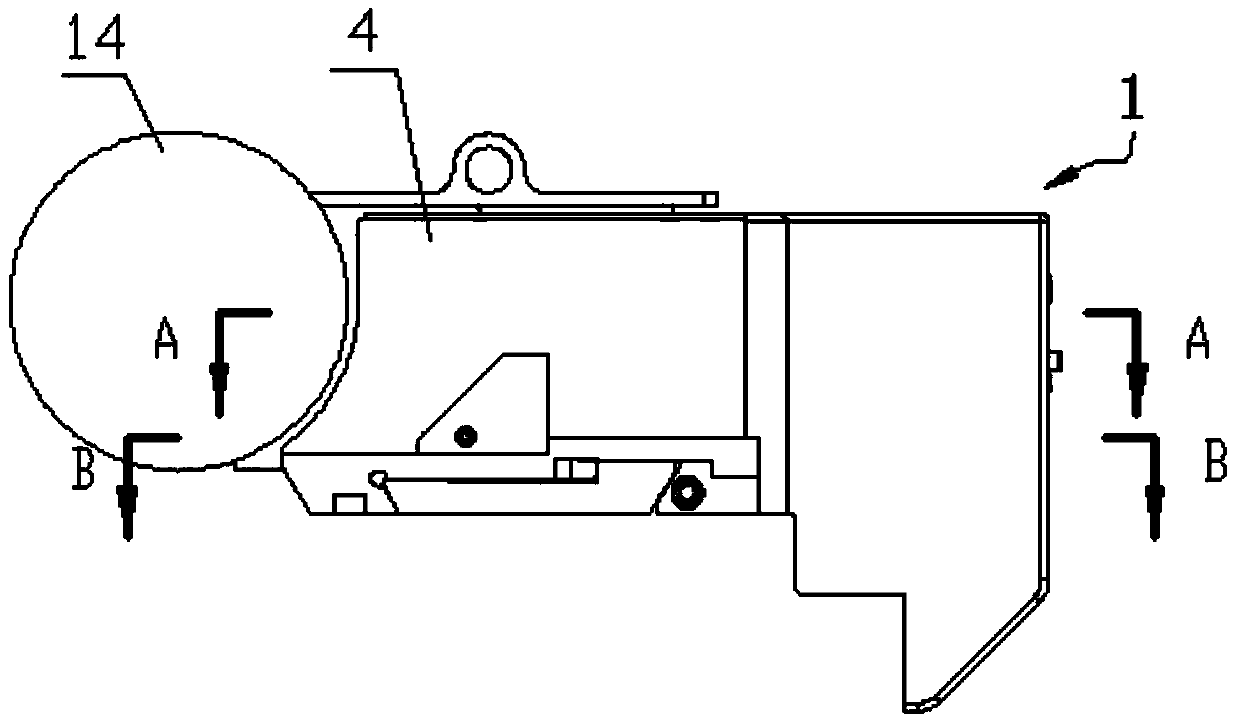

[0022] like figure 1 , 2 , the ink device of the present invention has 3 ink units 1, the 3 ink units 1 are arranged on one side of the ink roller 14 along the axial direction of the ink roller 14, and can move along the axial direction of the ink roller 14, so that each An ink unit 1 forms three independent ink supply areas at positions corresponding to the ink roller 14 .

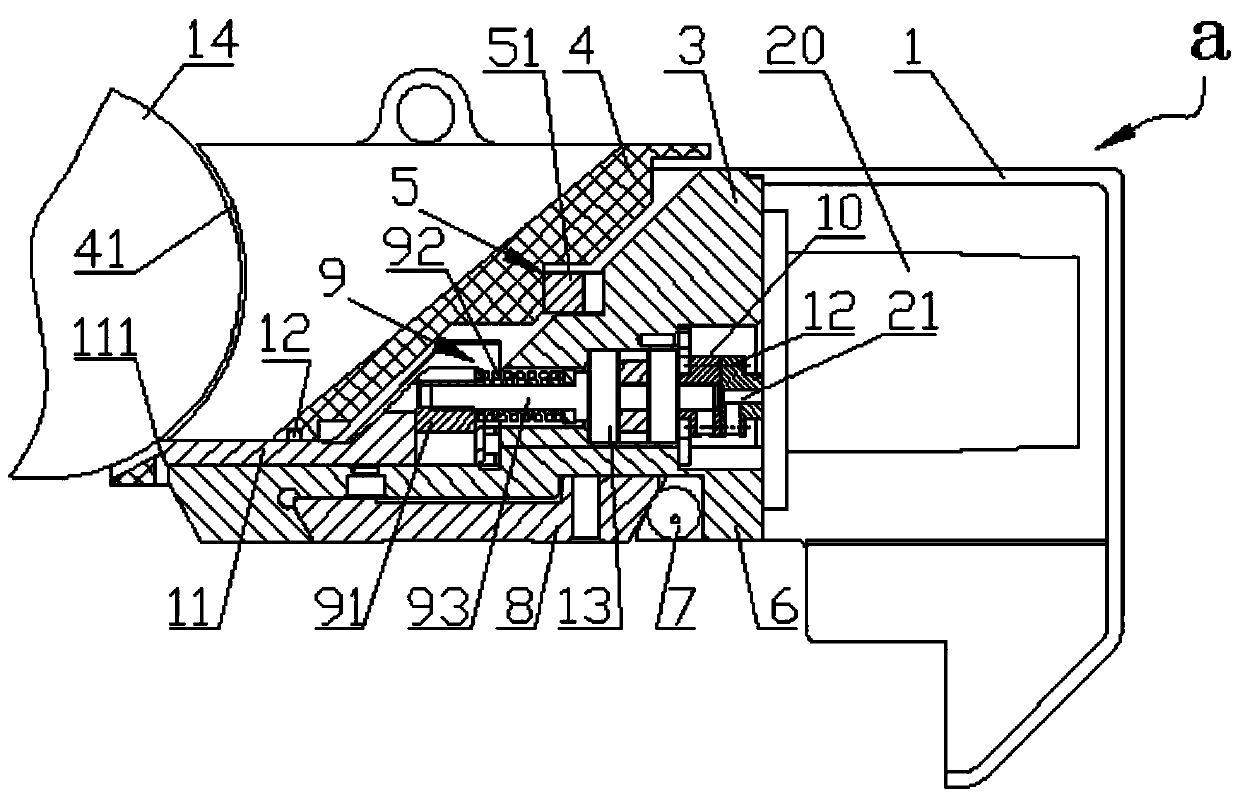

[0023] like image 3 , for each of the ink parts unit 1, including the ink knife 11, the ink knife box 4 and the ink layer adjustment mechanism 9 for adjusting the gap between the ink knife 11 and the ink roller 14 and for adjusting the ink knife box 4 and the ink roller 14 Gap automatic compensation mechanism 5. The ink layer adjustment mechanism 9 and the gap automatic compensation mechanism 5 are accommodated in an inner cavity formed by the combination of the upper casing 3 and the lower casing 6 . The ink knife 11 is arranged on one side of the ink roller 14 , and its edge line 111 is attached to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com