UV (Ultraviolet) straight printing method of 3D (Three-Dimensional) picture

A three-dimensional painting, 3D technology, applied in the field of 3D three-dimensional painting UV direct printing, to achieve the effect of reducing equipment cost, improving production speed, and reducing the number of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

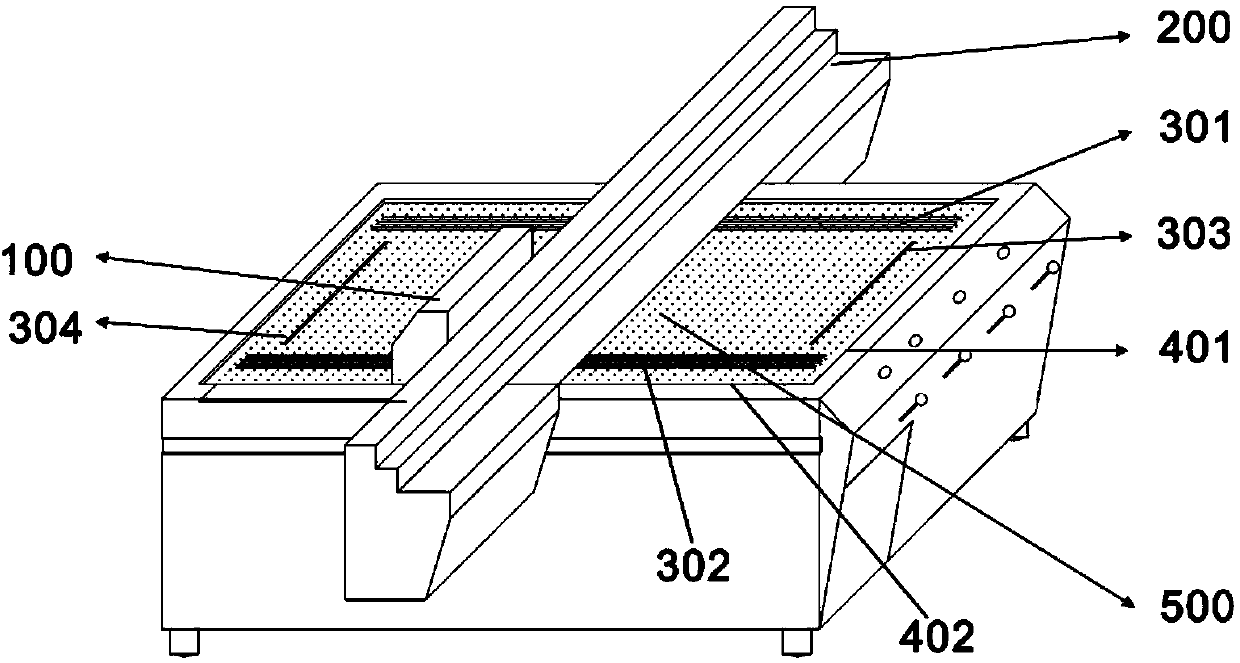

[0029] see figure 1 with 2 , this embodiment includes the following steps:

[0030] 1) According to the required screen size, cut the blank of the lenticular material to the corresponding size to obtain the lenticular material plate to be printed;

[0031] 2) After preparing the UV ink printing equipment, make accurate size measurement on the carrying platform of the flatbed direct printer, and then print out the alignment indicator line of the lenticular material plate to be printed and the horizontal and vertical data of the carrying platform on the carrying platform Marking lines; the alignment indicator lines are the alignment indicator lines 302 and 301 on the left and right sides of the bearing platform in the longitudinal direction, and the alignment indicator lines 304 and 303 on the left and right sides of the bearing platform; the horizontal and vertical data marker lines of the bearing platform are 401 and 402;

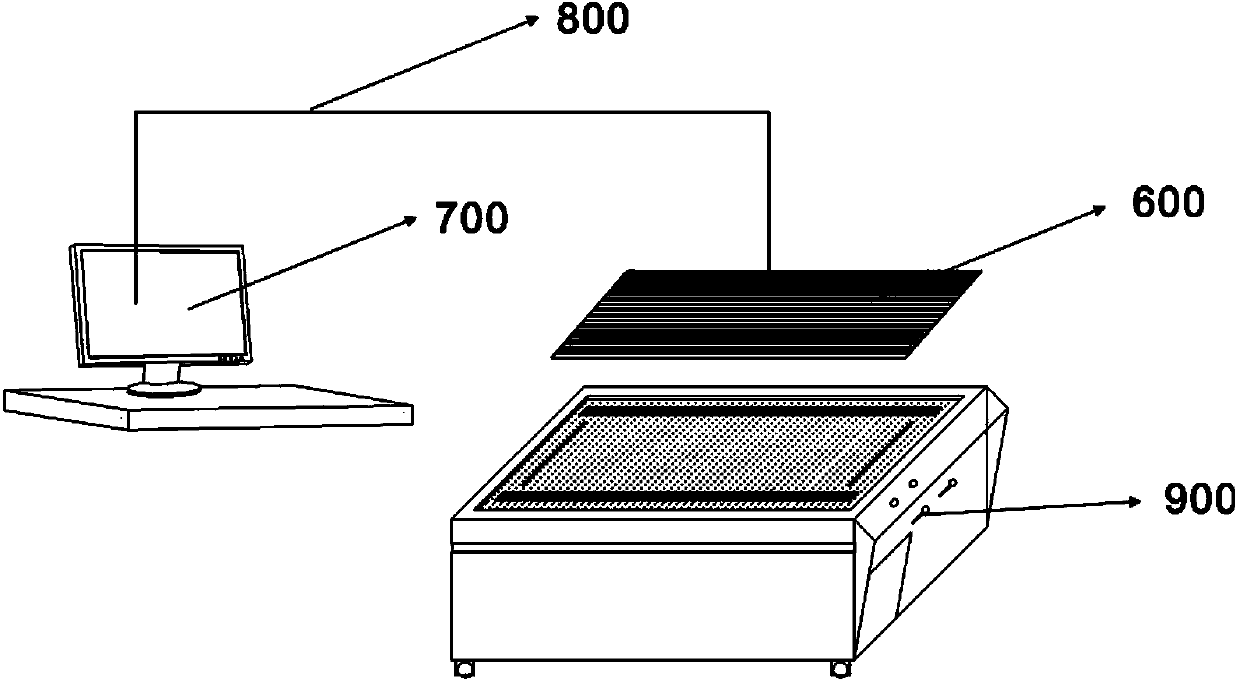

[0032] 3) Place the grating material plate 600 cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com