Quick connection and positioning structure for assembly of offshore buoyancy tanks

A technology for quick connection and positioning of the structure, applied in the direction of floating buildings, etc., can solve the problems of heavy weight, manpower and material resources, large joint volume, etc., and achieve the effect of light weight, cost saving and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

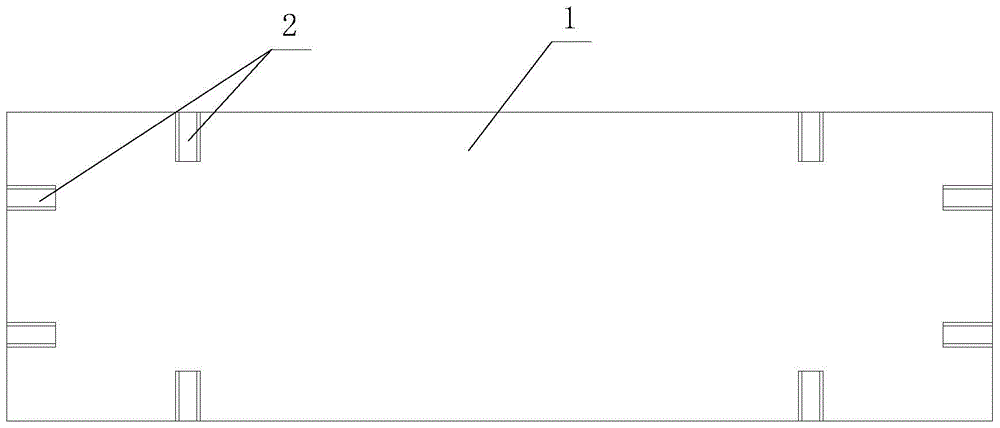

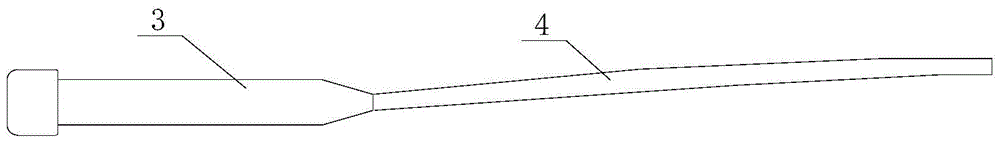

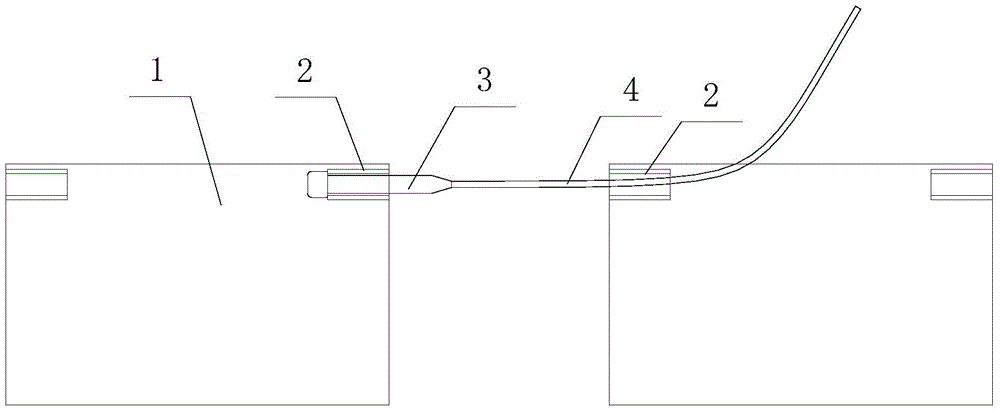

[0017] see Figure 1 ~ Figure 4 , a quick connection and positioning structure for assembly of offshore buoyancy tanks, comprising a connection positioning seat 2 and a connection positioning component arranged on a buoyancy tank module 1 .

[0018] Corresponding to each connection surface of the buoyancy tank module 1, at least two connection positioning seats 2 are installed, and a pin hole perpendicular to the connection surface is provided in the connection positioning seat 2 . In this embodiment, in order to facilitate the formation of pin holes, the connecting positioning seat adopts a tubular structure, usually a round tube or a square tube. The position of the connection positioning seat 2 in the vertical direction is near the deck s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com