Steel pipe material frame

A technology for steel pipes and material racks, applied in the field of material racks, can solve the problems that oil stains are not easy to drip automatically, affect processing efficiency, and have many oil stains on the pipe wall, etc., and achieve the effects of high toughness, enhanced practicability, and good aging resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

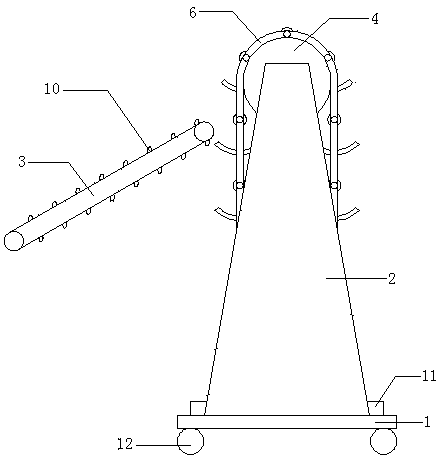

[0024] Such as figure 1 Shown is the front view of the present invention, the present invention is a steel pipe rack, including a base 1 , a support platform 2 and a pipe feeding device 3 .

[0025] An oil storage pan 11 is installed on the upper surface of the base 1 , and four universal wheels 12 are also installed on the bottom of the base 1 .

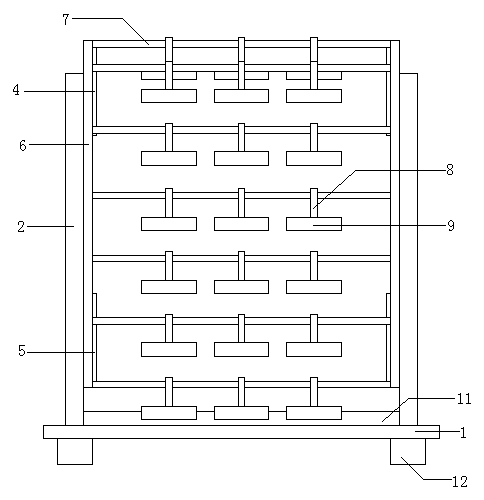

[0026] Such as figure 2 As shown, the support platform 2 is in the shape of an isosceles trapezoidal plate; the number of support platforms 2 is two, and they are symmetrically fixed on the base 1; a pair of upper gears 4 are installed symmetrically on the top of the two support platforms 2, and on the two supports ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com