Rotary Bar Grille Equipment

A rotary, grid technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of insufficient strength, easy blockage, short service life, etc. The effect of preventing clogging and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

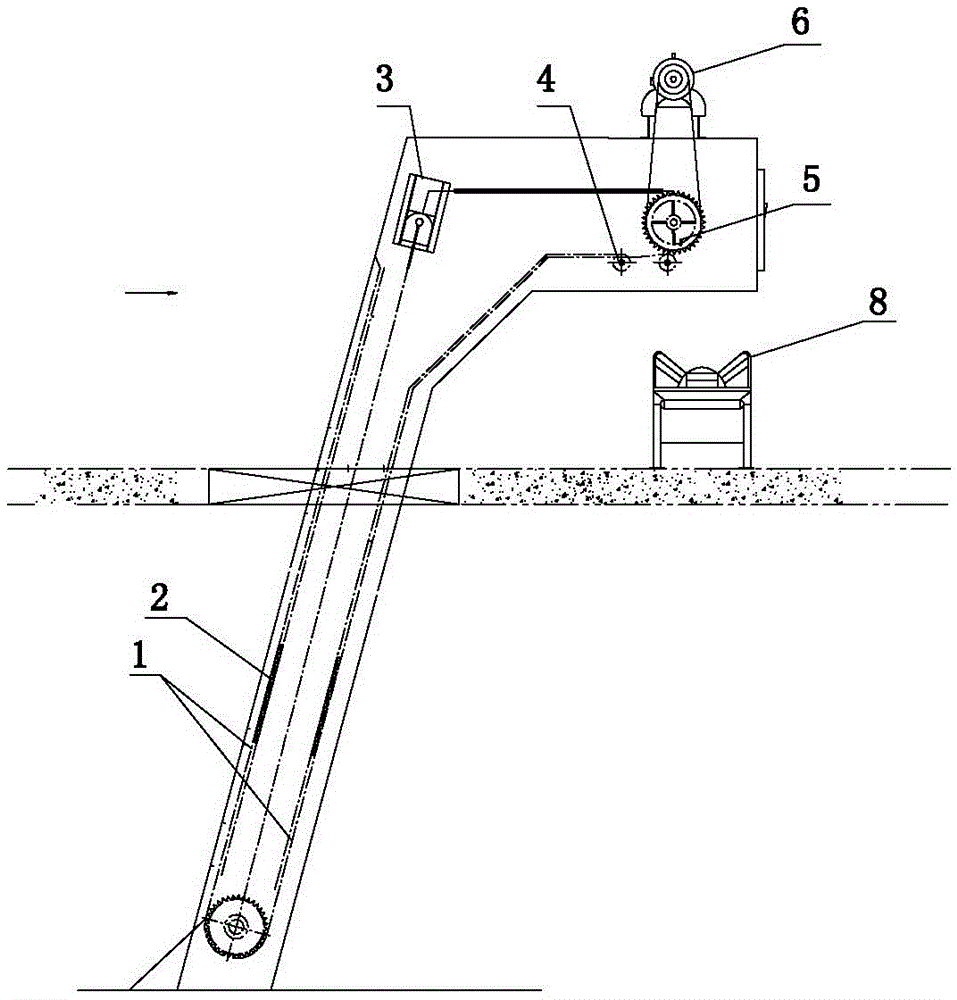

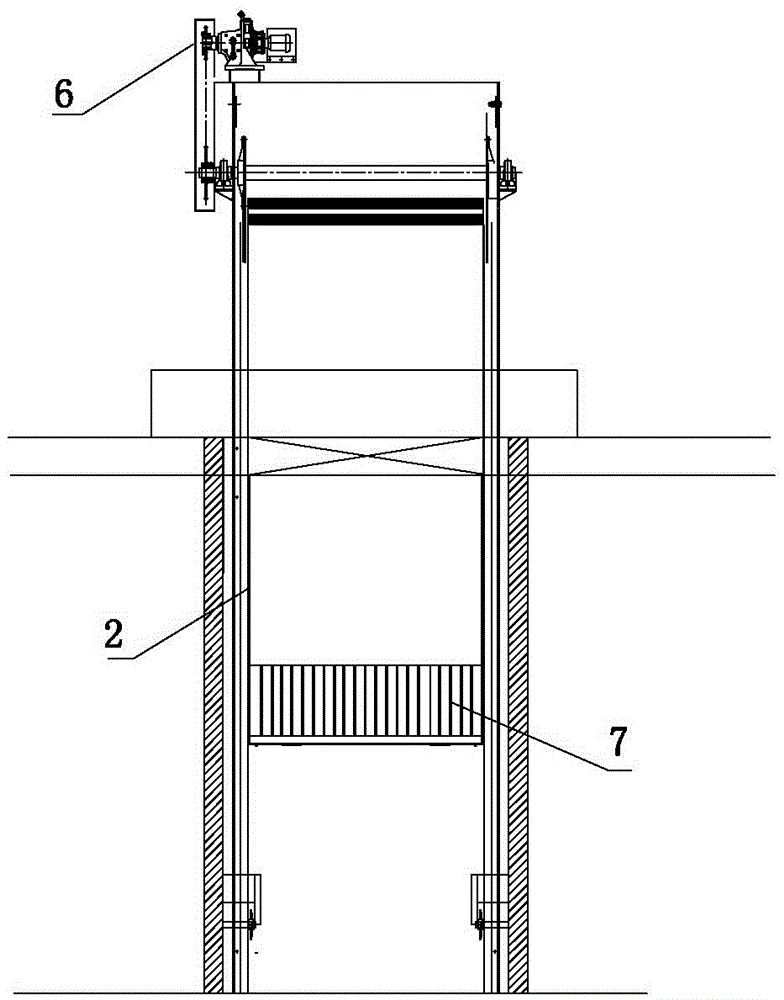

[0014] Such as figure 1 , 2 As shown, the present invention includes a traction chain 1, a grid chain 2 and a lifting system 3, the traction chain 1 and the grid chain 2 are driven by a drive system 6, and a Rotating brushes 4 and cleaning nozzles 5, the grid chain 2 is equipped with a plurality of horizontally arranged grid plates. The plurality of horizontally arranged grid chains form a group in pairs, and a plurality of cylindrical steel bars 7 perpendicular to the grid plates are welded between the two grid plates of the group. The plurality of cylindrical steel bars 7 are evenly arranged at intervals, so that the whole grid is integrated, the strength of the grid is improved, and the service life is increased. A belt conveyor 8 is provided below the highest point of the grid chain 2, and the sundries stopped by the grid are transported out by the belt conveyor 8. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com