Sewage treatment system with mutually communicated tanks

A technology of sewage treatment system and sewage treatment station, which is applied in the field of sewage treatment systems where pools and ponds are connected together, can solve the problems of easy loss of submersible sewage pumps, delay in construction period, inconvenient handling, etc., so as to prevent poor pumping and ensure efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

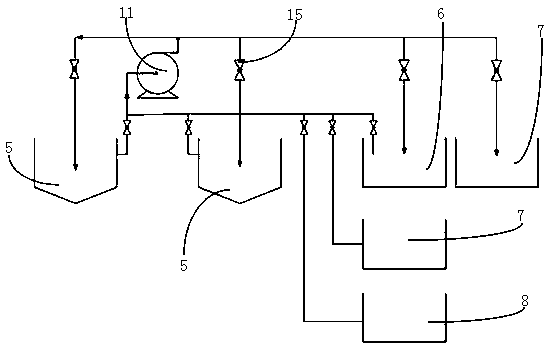

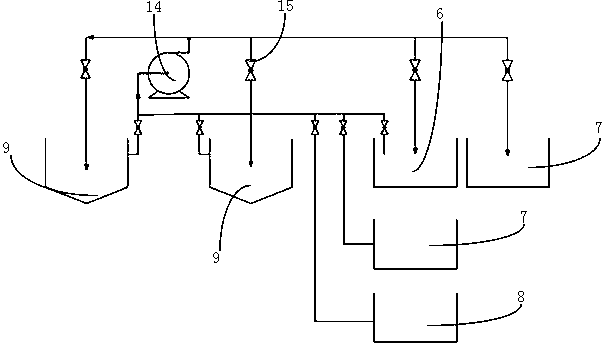

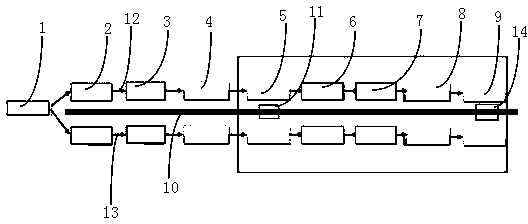

[0018] as attached figure 1 , attached figure 2 And attached image 3 As shown, a sewage treatment system with pools connected in series includes a raw water pool 1 and two sewage treatment stations, and each sewage treatment station includes a first reaction pool 2, a second reaction pool 3, and a first reaction pool connected in sequence. The flocculation tank 4, the first sedimentation tank 5, the third reaction tank 6, the fourth reaction tank 7, the second flocculation tank 8 and the second sedimentation tank 9, a partition wall 10 is set between adjacent sewage treatment stations, and a set Two corrosion-resistant self-priming pumps above the separation wall 10 and connected to the adjacent sewage treatment station. Each sewage treatment station adopts a linear design. Adjacent sewage treatment station, the first corrosion-resistant self-priming pump 11 inlets are respectively connected with the first sedimentation tank 5, the third reaction tank 6, the fourth reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com