High-speed automatic tucker for industrial sewing machine

An industrial sewing machine, high-speed technology, applied in the direction of sewing machine components, sewing equipment, cloth feeding mechanism, etc., can solve the problems of inconvenient adjustment, low sewing efficiency, unstable operation, etc., to improve stability, sewing efficiency and speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples illustrate the invention in detail.

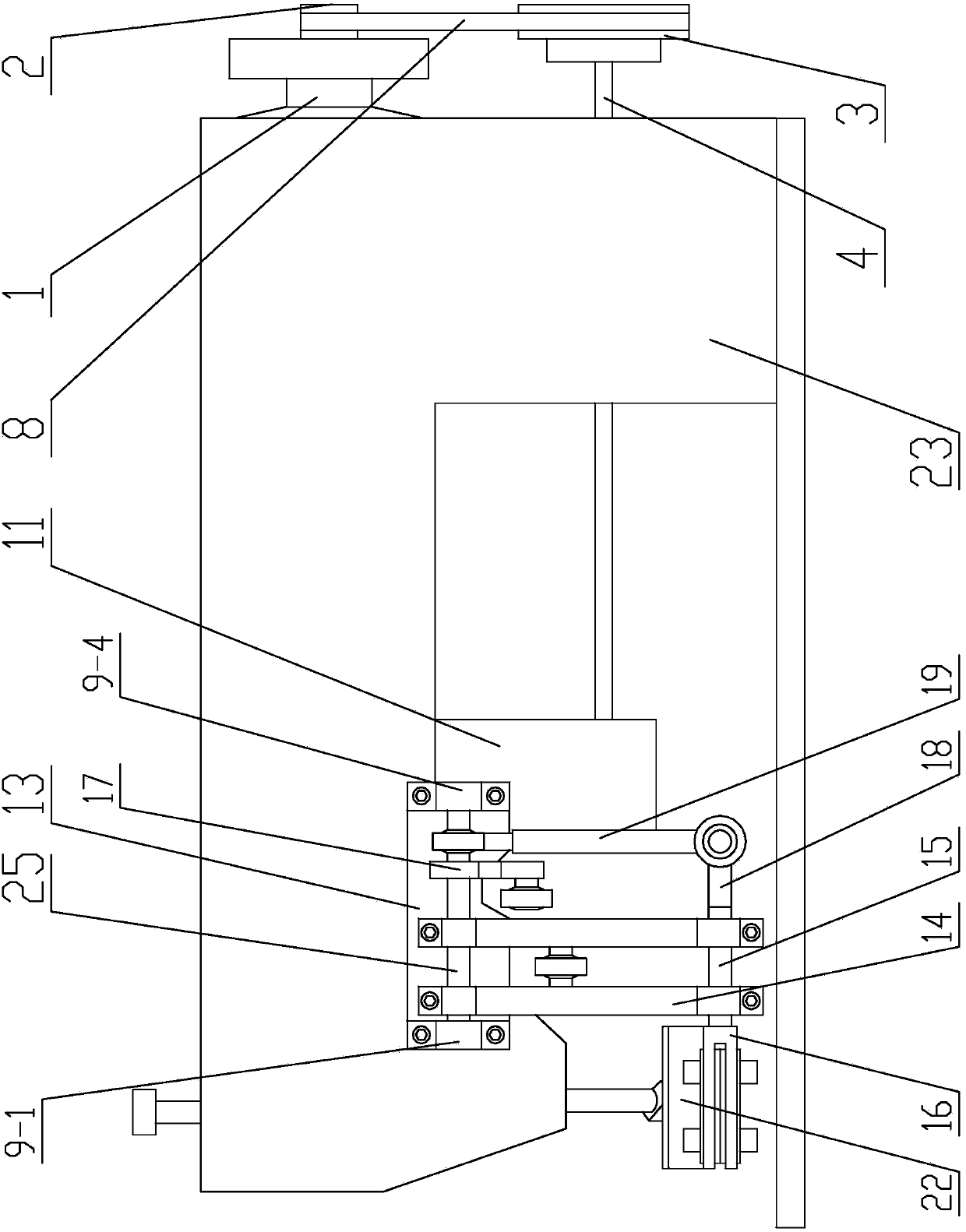

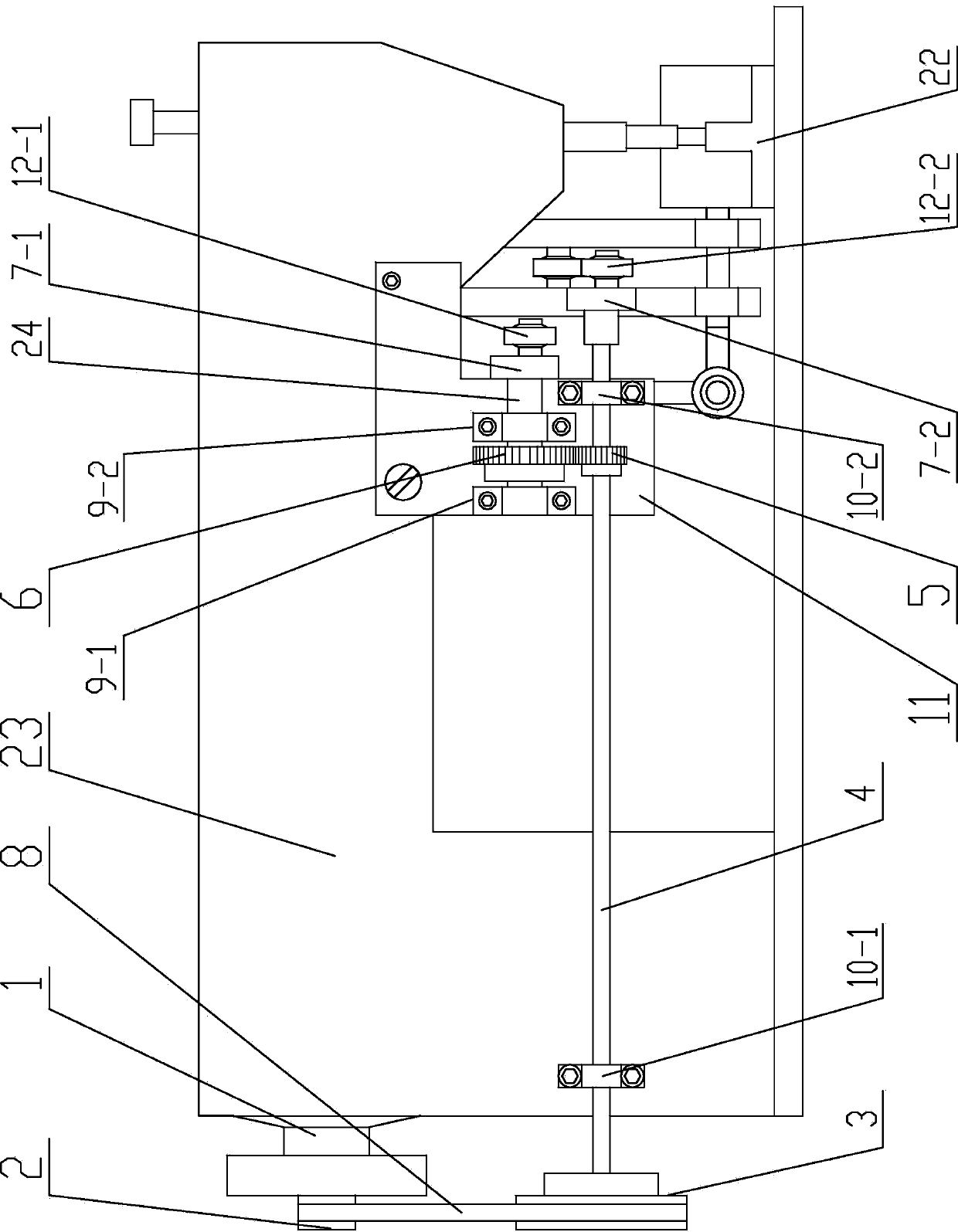

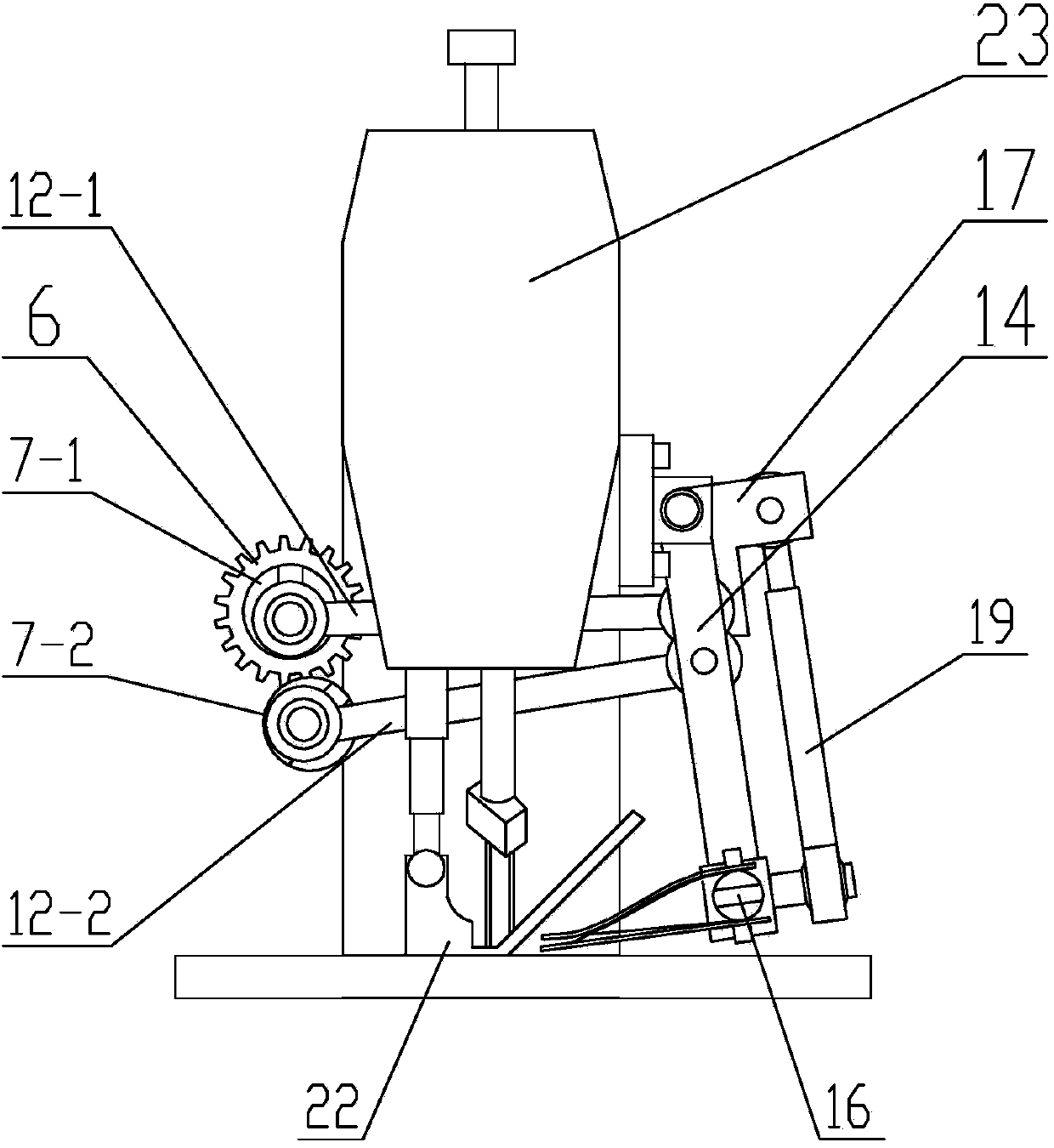

[0023] Such as Figure 1 to Figure 3 As shown, the present invention discloses a high-speed automatic pleating device for an industrial sewing machine, including a transmission shaft 4, a swing frame connecting rod 14 and a feeding blade; the transmission shaft 4 is installed on the back of the sewing machine body 23, and the swing frame connecting rod 14 is installed On the front of the sewing machine body 23, the position of the feeding blade corresponds to the presser foot of the sewing machine. The installation method of the transmission shaft 4 is as follows: two bearing seats 10-1, 10-2 are fixed on the back of the sewing machine body 23, and the transmission shaft 4 is sleeved in two bearing seats 10-1, 10-2 respectively. In the bearing. The pleating device of the present invention is directly installed on the sewing machine, using the motor of the sewing machine as the power source. The specific method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com