A Repairable Prestressed Concrete T-Girder Bridge

A concrete and prestressed technology, applied in the direction of bridges, buildings, etc., can solve the problems of easy damage, and achieve the effect of convenient transformation and repair, low price, convenient transformation and load lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

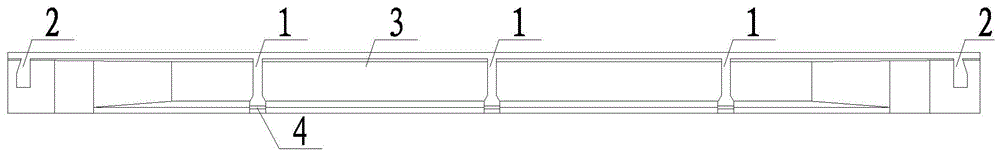

[0036] Such as Figure 1-3 As shown, a repairable prestressed concrete T-beam bridge includes a T-beam beam body 3, a middle diaphragm 1 and an end diaphragm 2; wherein, the middle diaphragm 1 adopts an external prestressed The steering block of the rib; the steering block is a rib plate type reinforced concrete block or a block type reinforced concrete block, and a guide pipe 4 is embedded in the block, and the guide pipe 4 is closely connected with the steel bars of the T beam beam body 3; the end The diaphragm 2 adopts an anchor block with external prestressed tendons; the anchor block is a block-type reinforced concrete block with a bellows channel reserved in the block, and the position where the anchor block is connected to the T-beam beam body 3 is set. There are steel angles.

[0037] The internal stirrup reinforcement method of the steering block and the anchor block is determined by using the finite element model combined with the tension and compression rod model, ...

Embodiment 2

[0054] A repairable prestressed concrete T-beam bridge, comprising a T-beam girder body 3, a middle diaphragm 1 and an end diaphragm 2; block; the steering block is a rib plate type reinforced concrete block or a block type reinforced concrete block, and a guide pipe 4 is embedded in the block, and the guide pipe 4 is closely connected with the steel bars of the T beam beam body 3; the end transverse diaphragm 2. An anchor block with external prestressed tendons is used; the anchor block is a block-type reinforced concrete block with a bellows channel reserved in the block, and an angle steel is provided at the position where the anchor block is connected to the T-beam body 3 .

[0055] When the steering block is a ribbed reinforced concrete block, the longitudinal section of the steering block is a ribbed horseshoe-shaped longitudinal section, and the width of the horseshoe is twice the rib width, and the longitudinal area of the horseshoe accounts for 15% of the total longi...

Embodiment 3

[0059] A repairable prestressed concrete T-beam bridge, comprising a T-beam girder body 3, a middle diaphragm 1 and an end diaphragm 2; block; the steering block is a rib plate type reinforced concrete block or a block type reinforced concrete block, and a guide pipe 4 is embedded in the block, and the guide pipe 4 is closely connected with the steel bars of the T beam beam body 3; the end transverse diaphragm 2. An anchor block with external prestressed tendons is used; the anchor block is a block-type reinforced concrete block with a bellows channel reserved in the block, and an angle steel is provided at the position where the anchor block is connected to the T-beam body 3 .

[0060] When the steering block is a ribbed reinforced concrete block, the longitudinal section of the steering block is a ribbed horseshoe-shaped longitudinal section, and the horseshoe width is 3 times the rib width, and the horseshoe longitudinal area accounts for 20% of the total longitudinal area o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com