CFG pile composite roadbed rubber spacer static load testing device and method

A technology of rubber cushion and composite roadbed, which is applied in the test of foundation structure, foundation structure engineering, construction, etc., and can solve problems such as large errors, lateral flow of sand grains, and inability to guarantee the stiffness and thickness of the cushion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the embodiments.

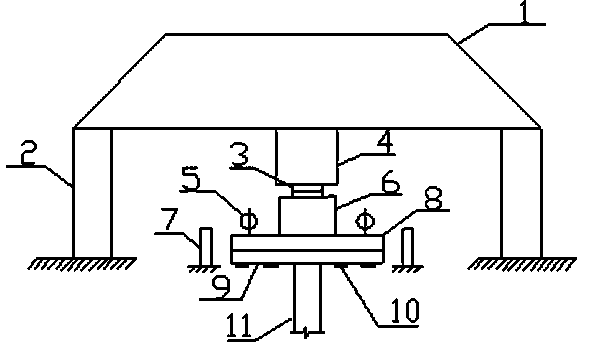

[0048] Such as figure 1 As shown, the present invention discloses a static load test device for CFG pile composite subgrade rubber cushion, comprising the following components: reaction force test block 1, support beam 2, dynamometer 3, reaction force beam 4, displacement meter 5, Jack 6, reference beam 7, rubber pad 8, pressure bearing plate 9, earth pressure gauge 10, CFG test pile 11, wherein, the upper end of the CFG test pile 11 is coaxially arranged with pressure bearing plate 9 and rubber pad sequentially from bottom to top 8. Jack 6, reaction beam 4; earth pressure gauge 10 is arranged on the bottom surface of the pressure bearing plate 9; displacement gauge 5 is arranged on the rubber pad 8; force measuring is arranged coaxially between the jack 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com