Pipeline leakage positioning method based on fuzzy reasoning

A technology of pipeline leakage and positioning method, which is applied in the field of pipeline detection and can solve problems such as complex methods and poor positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

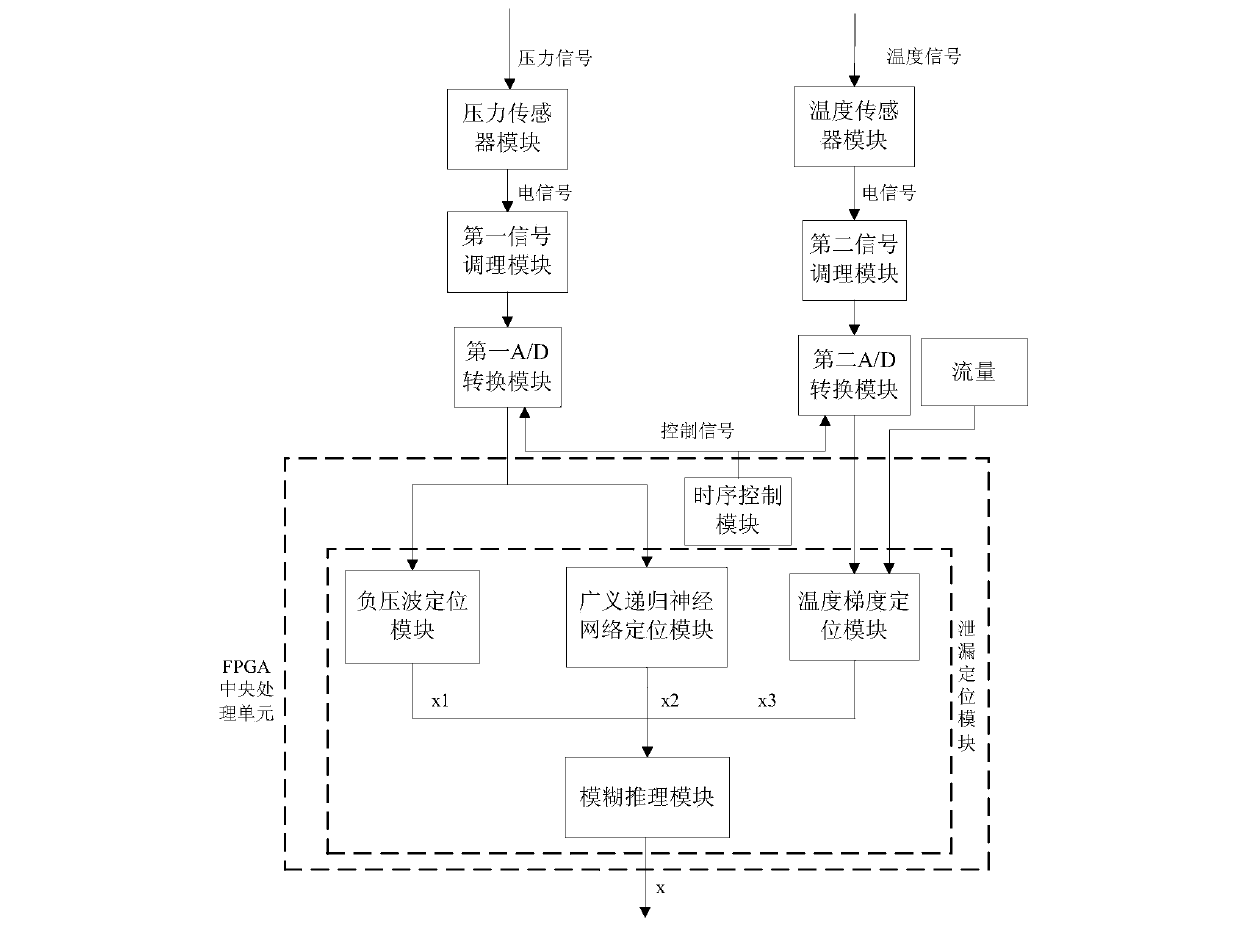

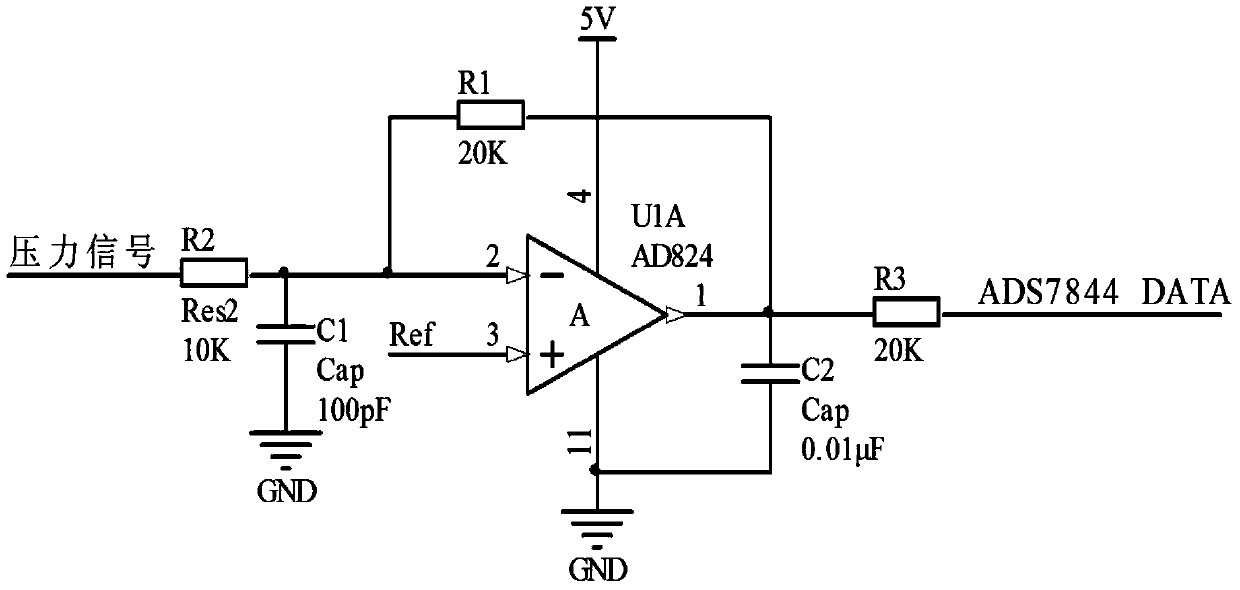

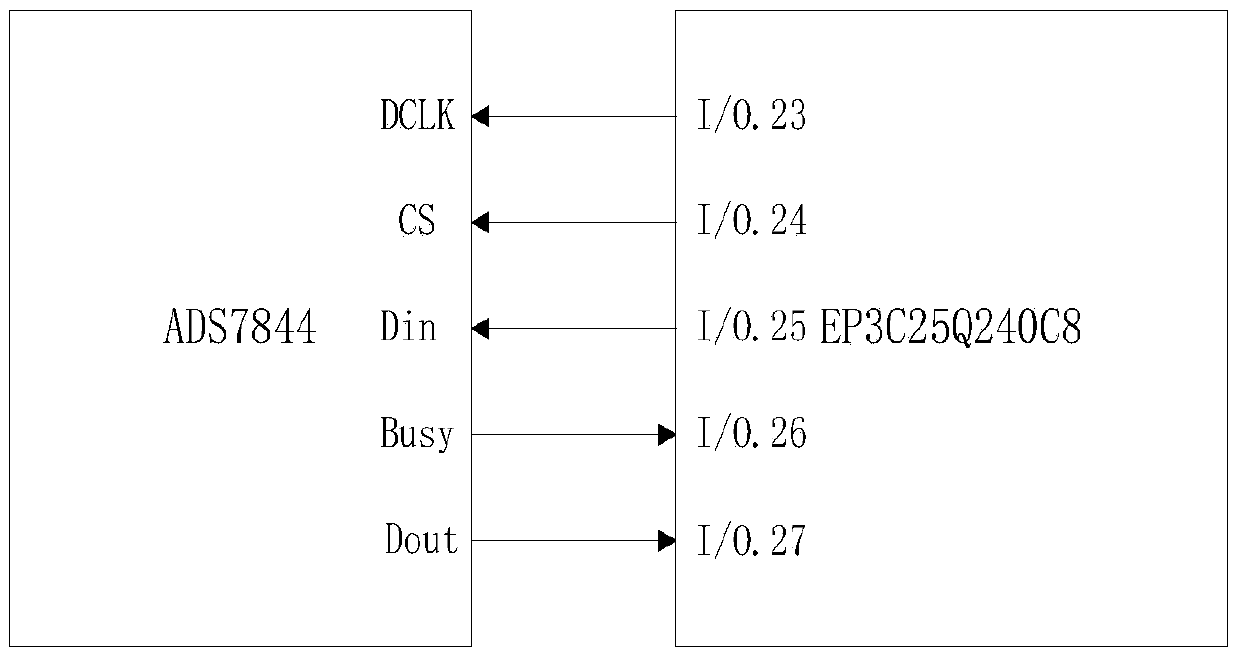

[0041] In this embodiment, the pipeline leakage location device based on fuzzy reasoning used to realize the pipeline leakage location method based on fuzzy reasoning, such as figure 1 As shown, the device includes a pressure sensor module, a temperature sensor module, a first signal conditioning module, a second signal conditioning module, a first A / D conversion module, a second A / D conversion module and an FPGA central processing unit, wherein the FPGA central processing unit The processing unit module includes a timing control module and a leak location module based on fuzzy reasoning. The timing control module is used to generate the working sequence of the A / D conversion module. The leak location module based on fuzzy reasoning includes a negative pressure wave location module and a generalized recursive neural network locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com