Multiple-point-distribution LED lamp

A technology for LED lamps and LED bulbs, applied in the field of LED lighting, to achieve the effects of easy operation and realization, improved heat dissipation efficiency, and good market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

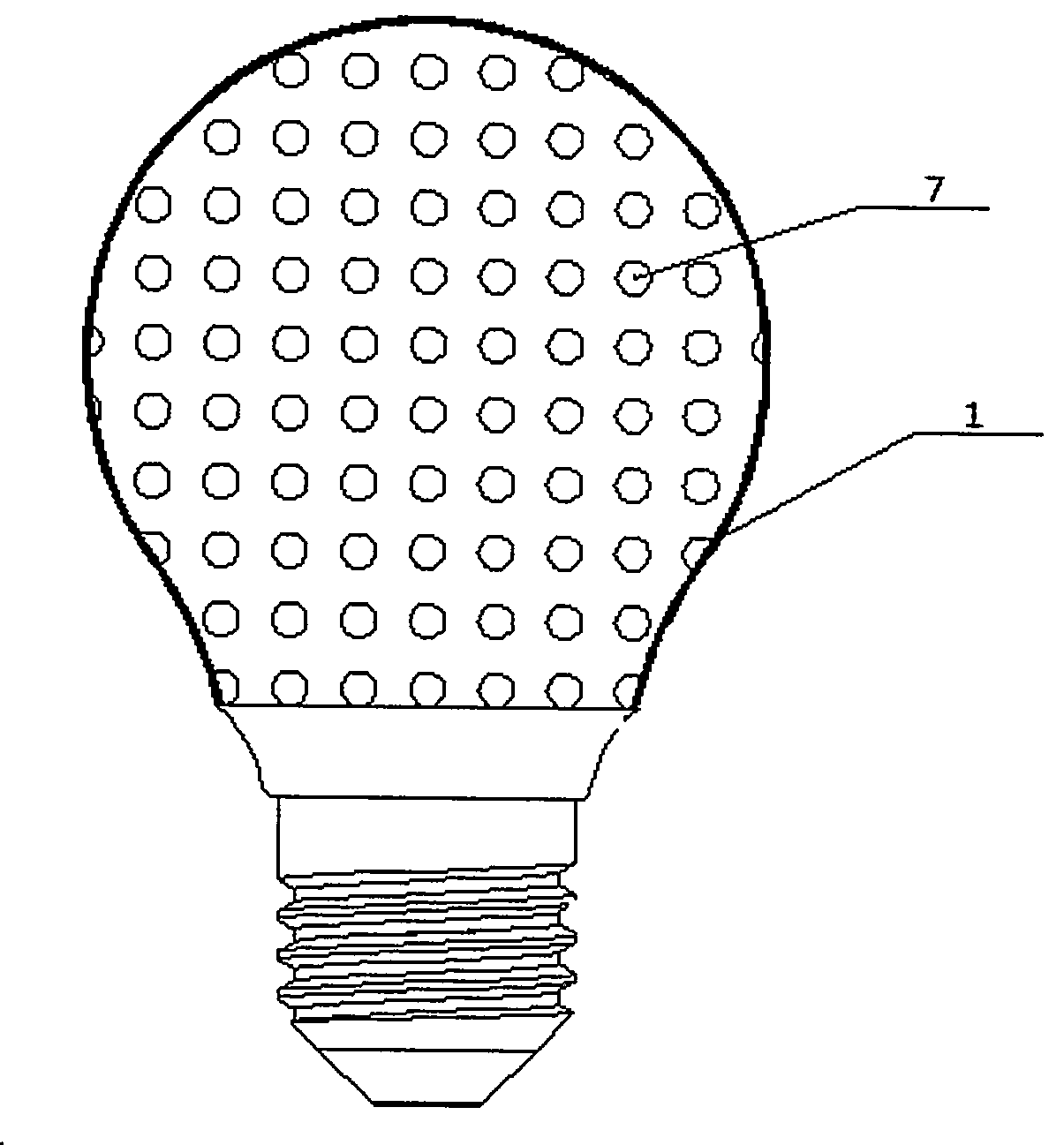

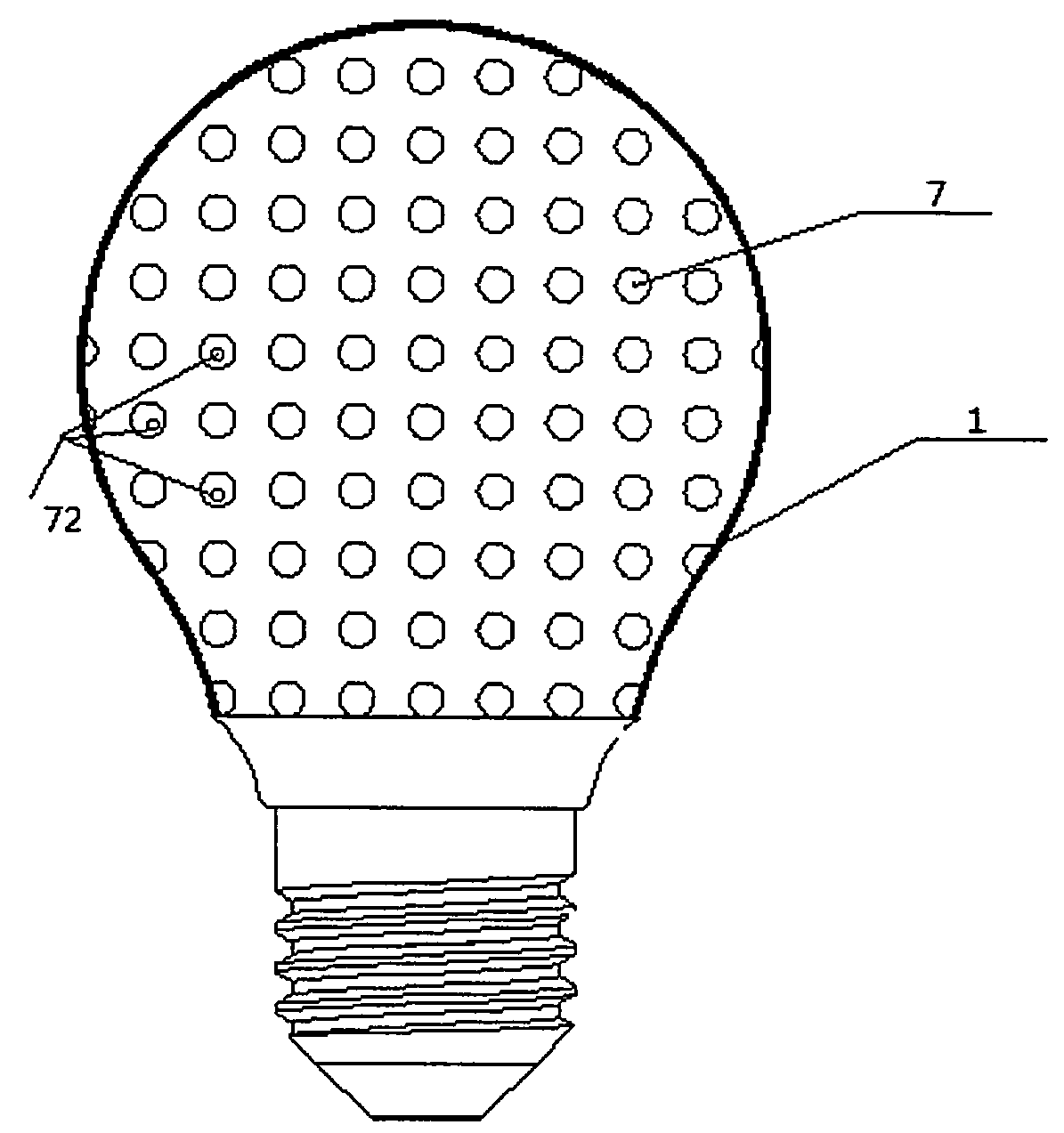

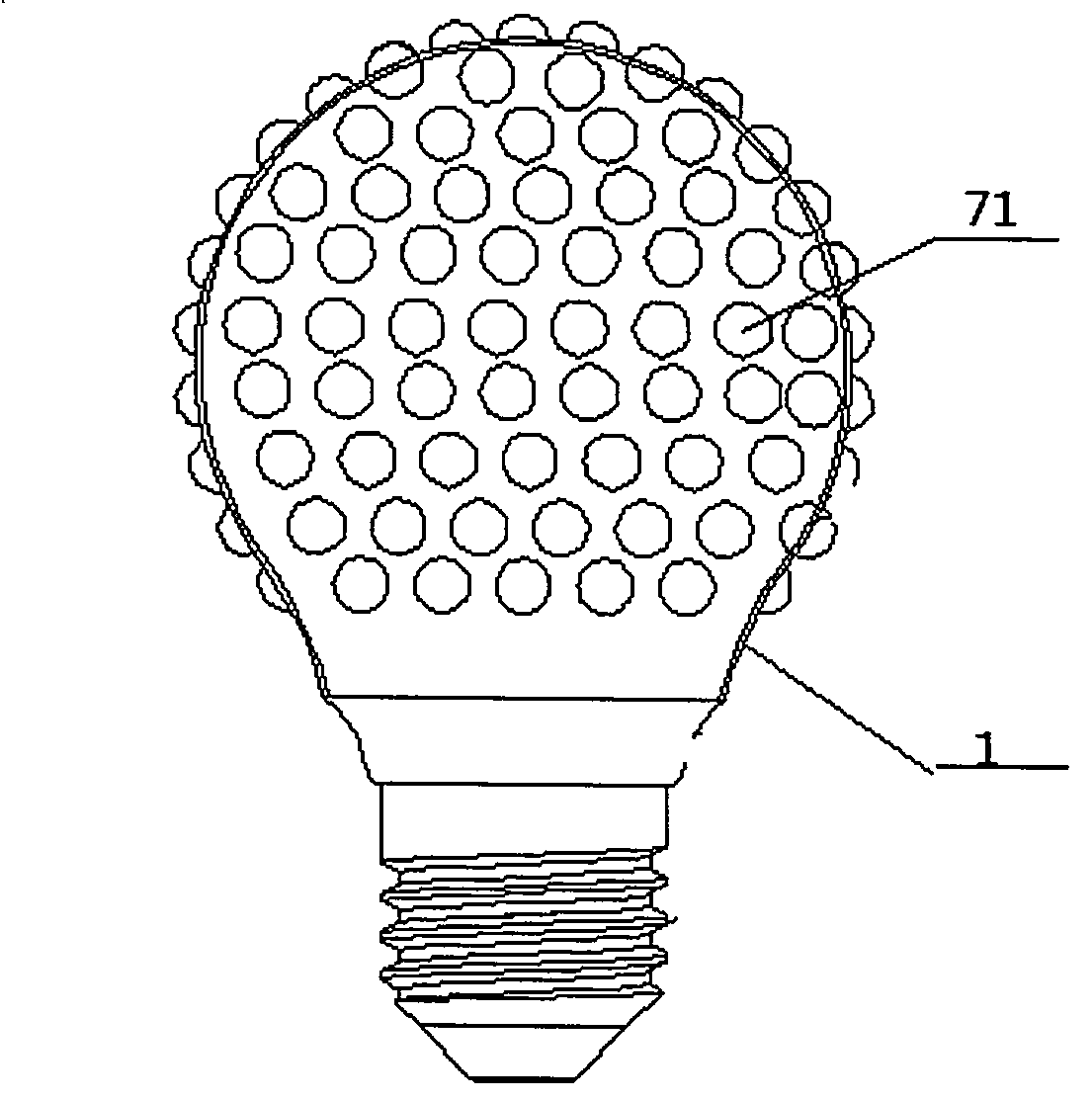

[0034] Those skilled in the art understand that the present invention mainly provides a multi-point distributed LED lamp. The advantage of using a multi-point distributed LED lamp is that it can make the LED lamp have better heat dissipation performance, and its function of improving heat dissipation efficiency is mainly The heat dissipation point 7 is provided on the LED bulb shell 1 to achieve this. The heat dissipation point 7 can additionally increase the heat dissipation area, so that the heat in the bulb shell 1 can be dissipated more quickly and fully.

[0035] specifically, figure 1 A schematic structural diagram of an LED lamp according to a specific embodiment of the present invention is shown. The present invention provides a multi-point distributed LED lamp, which at least includes an LED bulb shell 1, an LED light-emitting chip group 3 ( figure 1 not shown), the LED light-emitting chipset 3 is placed in the LED light bulb shell 1, wherein, the outer surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com