Control method of electronic expansion valve of air conditioner

An electronic expansion valve and control method technology, applied in heating and ventilation control systems, refrigerators, heating methods, etc., can solve the problems of increasing the maintenance probability of air conditioners, shortening the service life of capacitors, etc., to achieve reliable design solutions and reduce start-up The effect of reducing resistance and inrush current values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

[0018] The invention provides a method for controlling the electronic expansion valve of an air conditioner. The electronic expansion valve is used as the main throttling device of the air conditioner system, and the opening of the electronic expansion valve is fully opened when starting up to reduce the refrigerant pressure difference at both ends of the system throttling device. , reduce the starting resistance of the compressor, and then reduce the starting current.

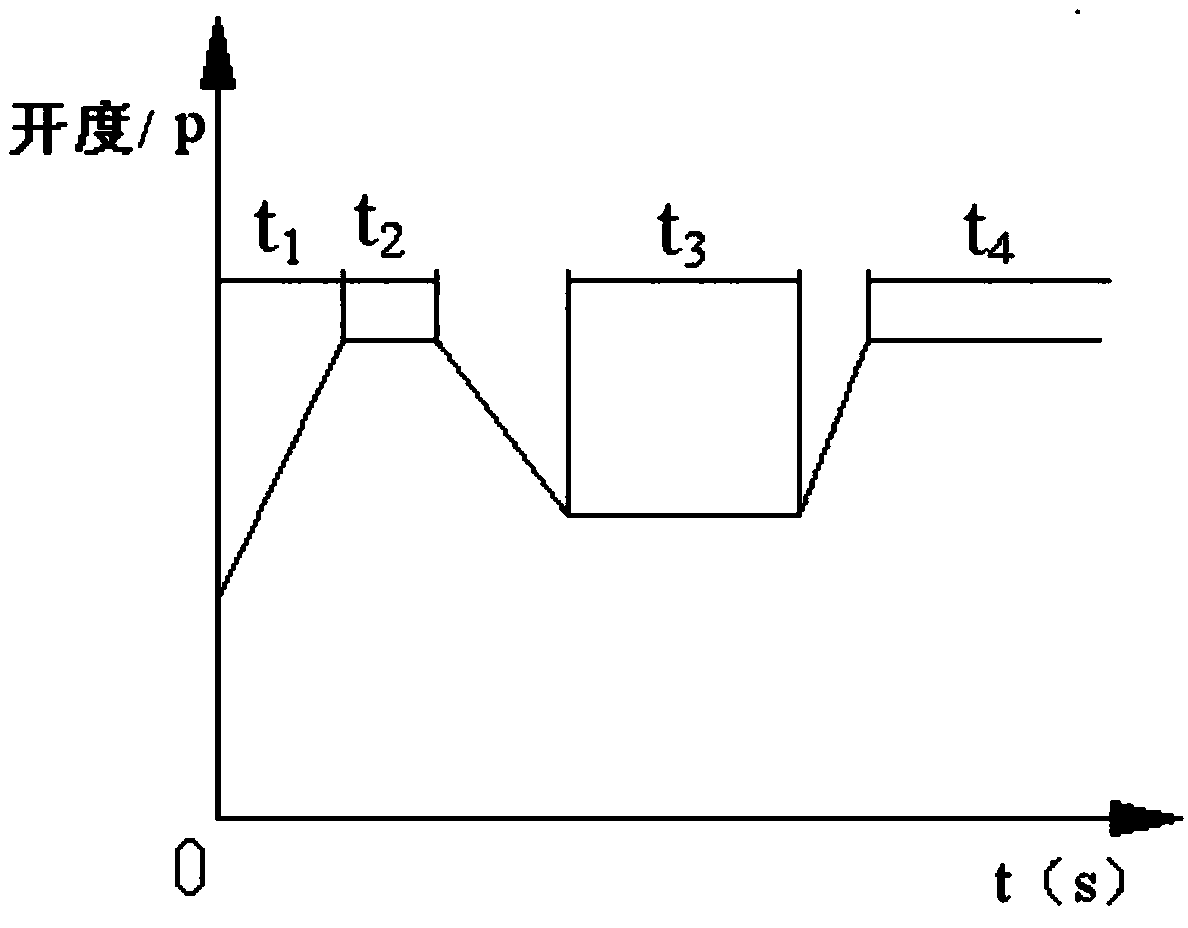

[0019] Such as figure 1 The control process of the present invention shown. In the picture:

[0020] t 1 Indicates the time for the electronic expansion valve t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com