Hydraulic motor glue wheel-supported stepless transmission drum mixer

A cylinder mixing and hydraulic motor technology, applied in mixers, mixers with rotating containers, dissolving, etc., can solve the problems of fast wear of idler rollers, high power of motors, and insufficient supporting force of rubber wheels, etc., to achieve material mixing and The effect of uniform granulation, large load bearing capacity and small starting resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

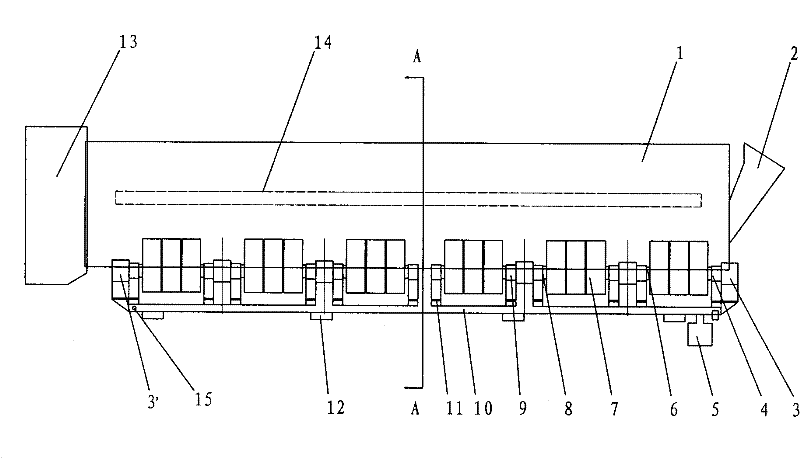

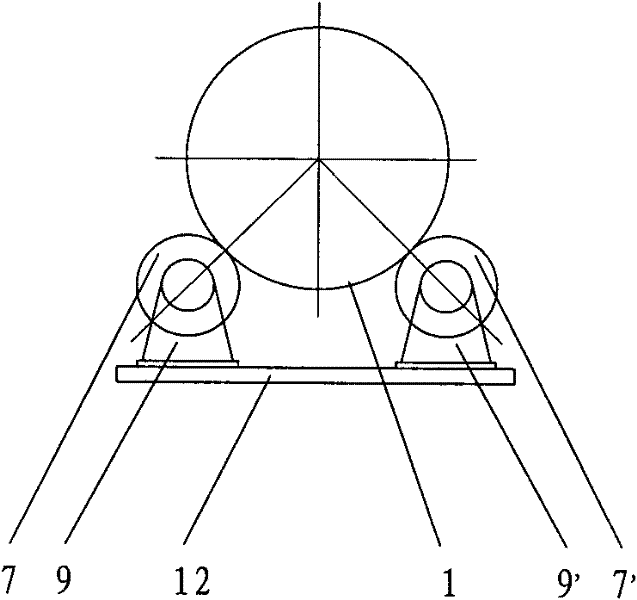

[0021] figure 1 It is the cylinder mixer with stepless transmission supported by the rubber wheels of the first hydraulic motor disclosed in the present invention. The cylinder body 1 of the cylinder mixer is provided with two sets of rubber wheel driving groups at radially symmetrical positions on both sides. The rubber wheels The transmission group is composed of the first hydraulic motor 3, the driving main shaft 6, the first rubber wheel group 7, the self-aligning bearing 8, the first bearing seat and the bracket 9, and three sets of the first rubber wheel group 7 are installed on the driving main shaft 6, each group The first rubber wheel group 7 is equipped with 3 tires. The driving main shaft 6 is installed in the shaft hole of the self-aligning bearing 8 of the first bearing seat and the bracket 9, the driving main shaft 6 is connected with the output shaft of the first hydraulic motor 3 through the shaft coupling 4, and the first hydraulic motor 3 drives the main sha...

Embodiment 2

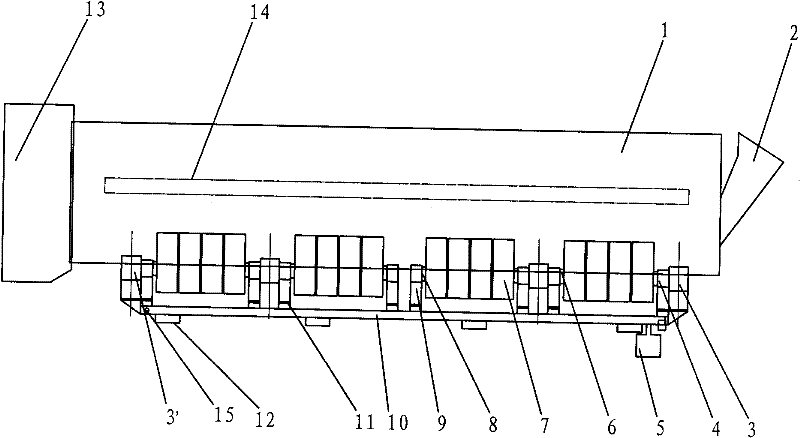

[0023] image 3 It is a cylindrical mixer with stepless transmission supported by rubber wheels of the second hydraulic motor disclosed in the present invention. The cylinder body 1 of the cylindrical mixer is driven by two sets of rubber wheel driving groups located at radially symmetrical positions on both sides of the cylindrical mixer. 2 groups of first rubber wheel groups 7 are installed on the main shaft 6, and every assembly has 4 tires. Others are the same as in Example 1.

Embodiment 3

[0025] Figure 4 It is the third hydraulic motor rubber wheel supported stepless transmission cylinder mixer disclosed in the present invention. The cylinder body 1 of the cylinder mixer is driven by two sets of rubber wheel driving groups located at radially symmetrical positions on both sides of the cylinder mixer. 3 groups of first rubber wheel groups 7 are installed on the main shaft 6, wherein 2 are assembled with 4 tires, and the other is assembled with 2 tires. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com