Bulk cargo conveying tank reconstructed through container

A container and conveying tank technology, which is applied in the field of container transformation into bulk material conveying tanks, can solve the problems of lack of bulk materials, difficulty in unloading, and small loading capacity, and achieve the effects of efficient work, safety protection, and speeding up.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

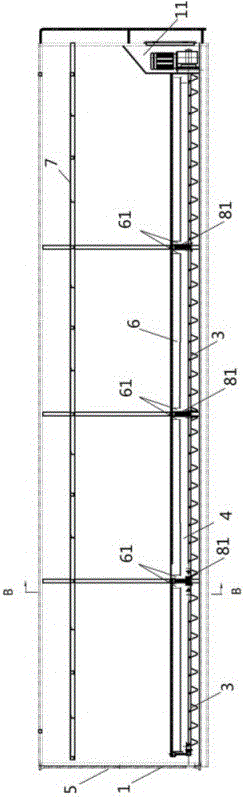

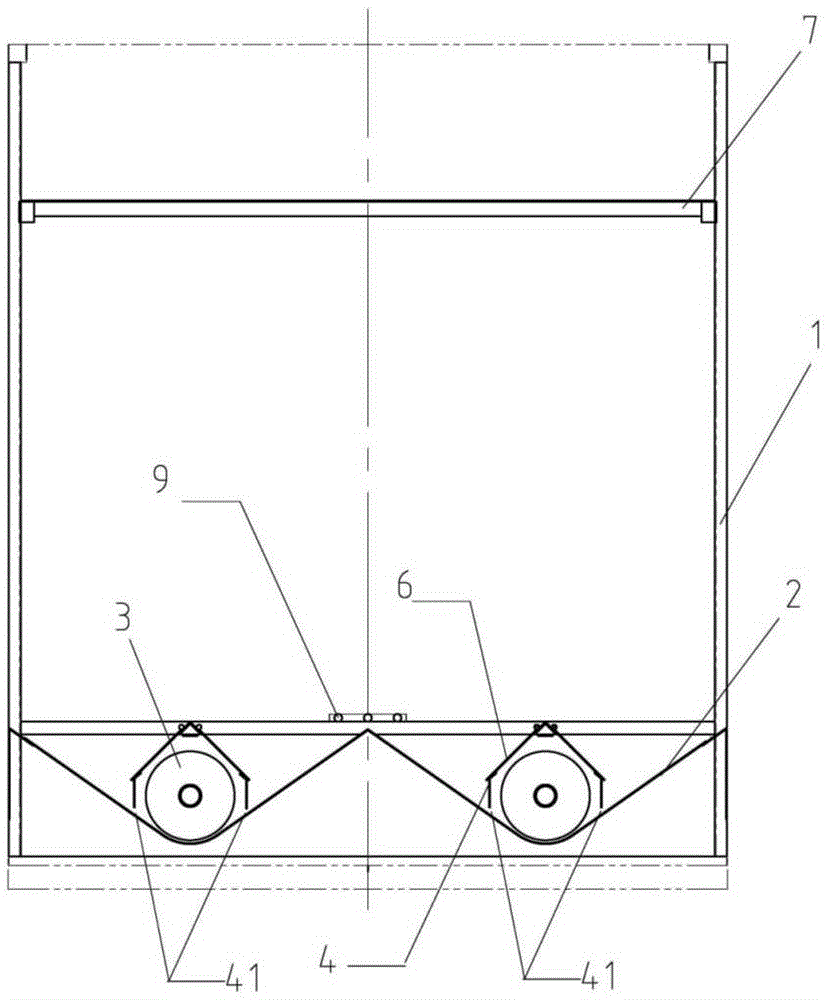

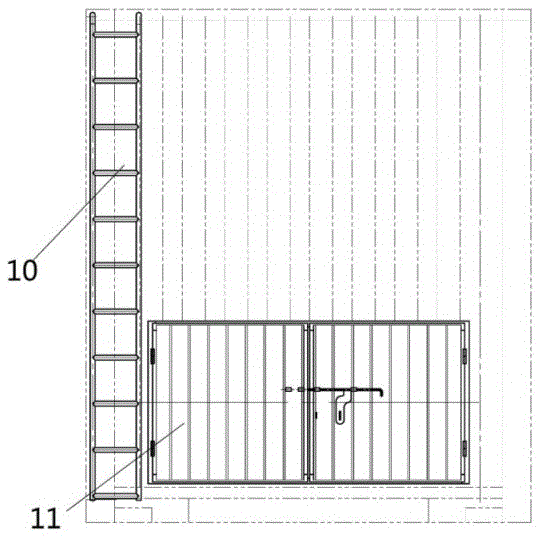

[0024] refer to figure 1 , figure 2 and image 3 , the container is remade into a bulk material conveying tank, including a container body 1, and the container body 1 includes a box top, a box bottom and a box door 5, and it is characterized in that the box bottom is a W-shaped box bottom 2, and the two sides of the W-shaped box bottom 2 Each of the lower recesses is provided with a horizontal auger discharge device 3, and a deflector is arranged above the horizontal auger 3.

[0025] The bottom of the common container is a flat plate, which is not convenient for laying the horizontal auger. It is transformed into a W-shaped bottom, so that the horizontal auger 3 is placed on two sunken positions of the W shape. The horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com