Spatial position simulation and calibration method

A technology of spatial position and calibration method, applied in the direction of measuring devices, optical devices, instruments, etc., to achieve the effect of high centering accuracy, low cost, and strong universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below with reference to the accompanying drawings.

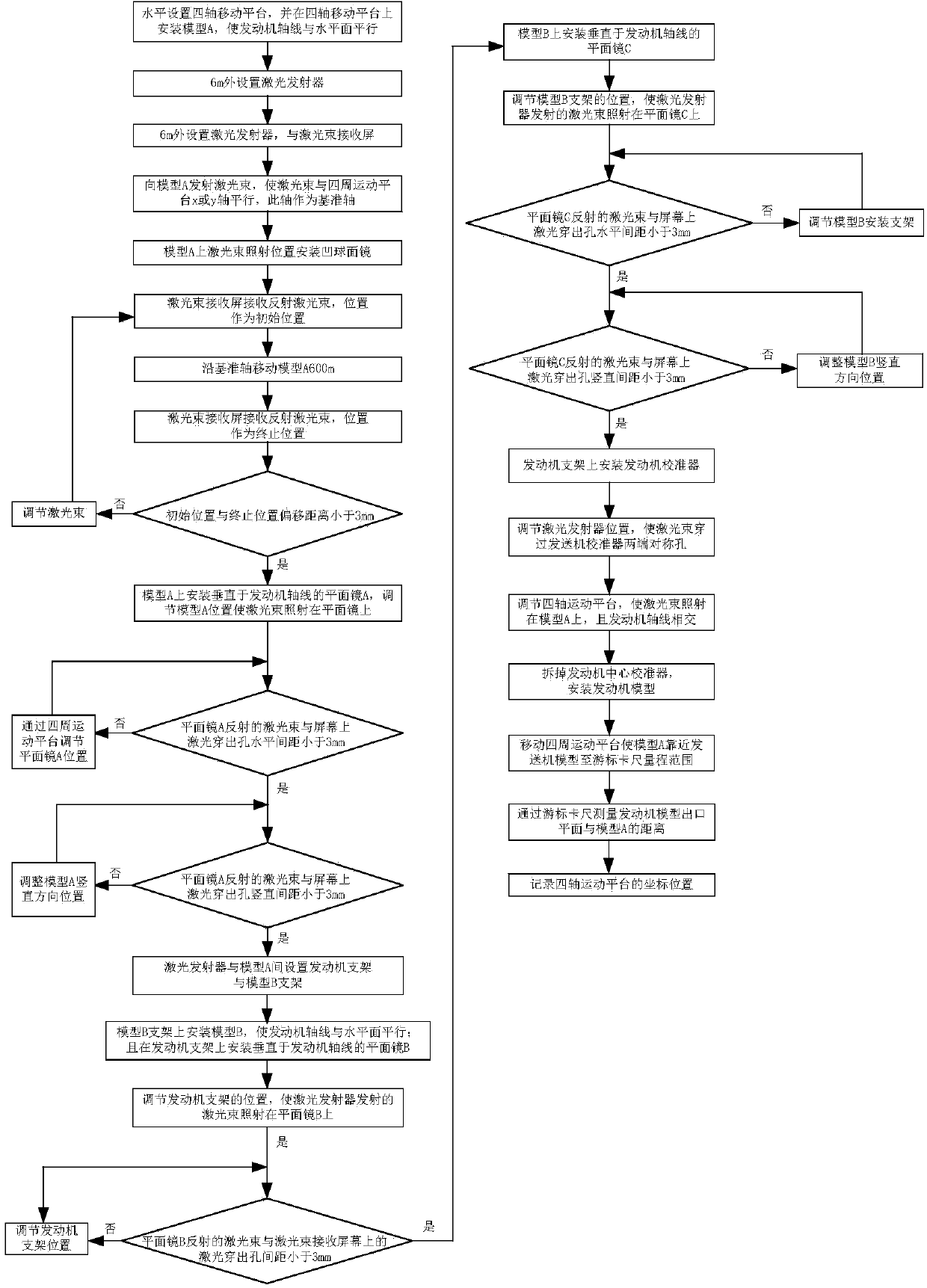

[0043] The spatial position simulation and calibration method of the present invention is specifically completed through the following steps, such as: figure 1 shown:

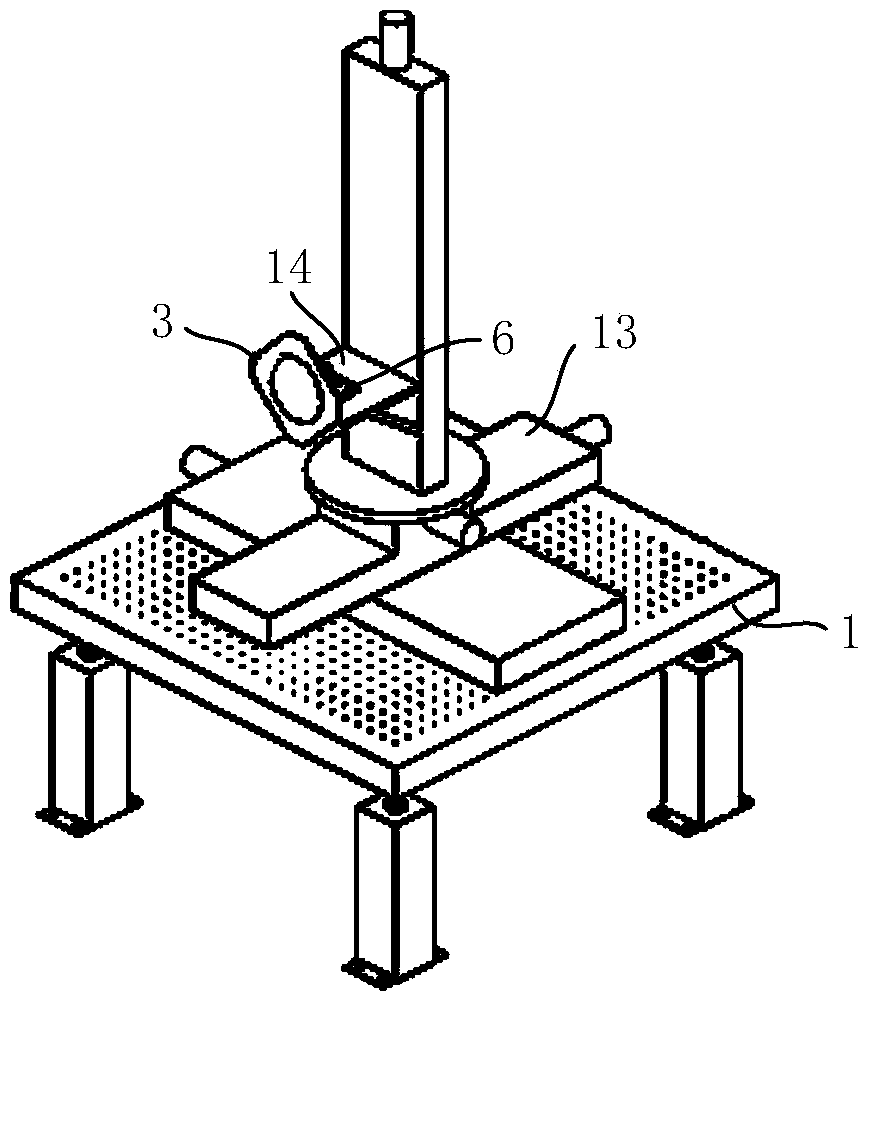

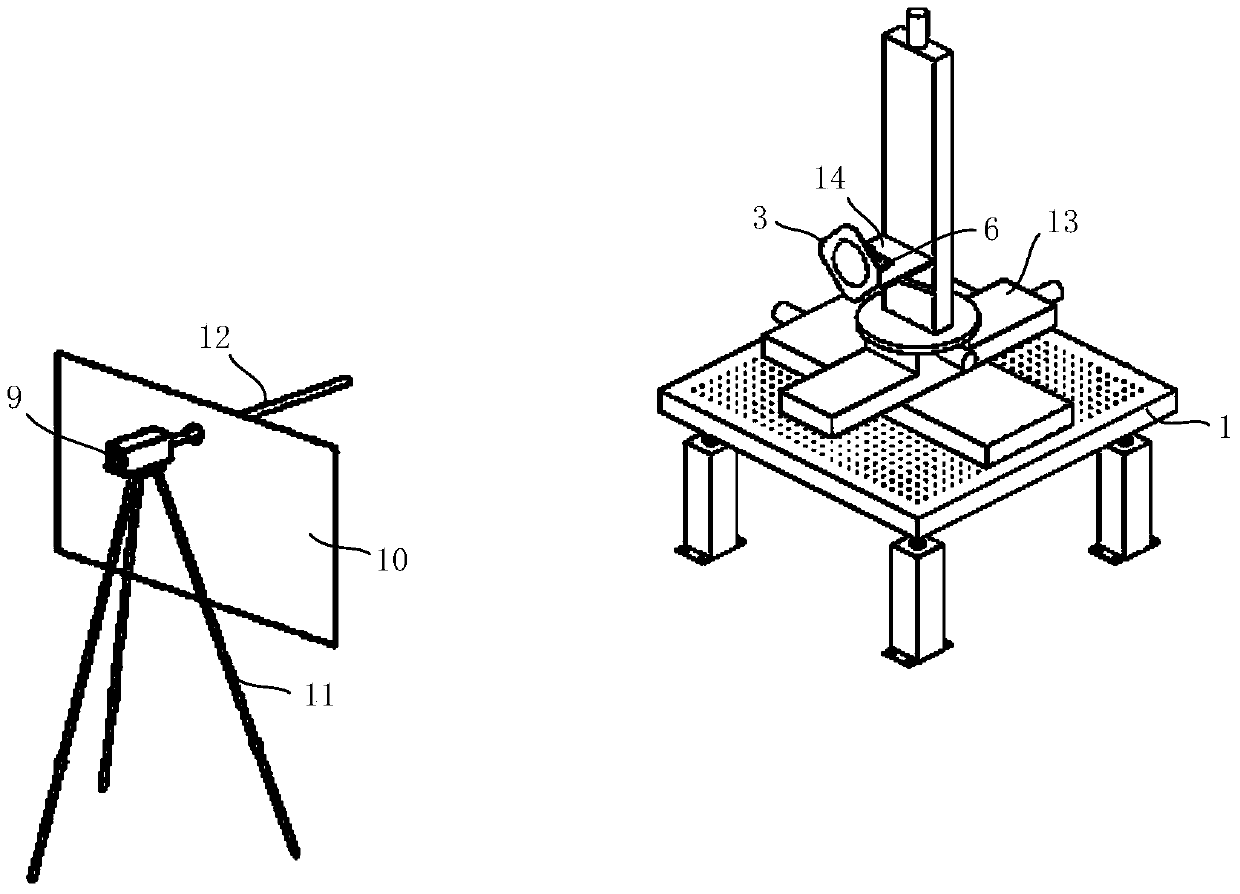

[0044] Step A: Place the assembled four-axis motion platform 13 on the optical platform A1, such as figure 2As shown, the plane formed by the x and y axes of the four-axis motion platform 13 is made parallel to the surface of the optical platform A1; the optical platform A1 is leveled with a high-precision level. Let the separated or docked parts in the spacecraft (such as the lander and ascender of the Chang'e series lunar lander.) be part A and part B respectively; according to the actual spacecraft size, the spacecraft is scaled or reduced in equal proportions, and the The part A, part B and the spacecraft engine are made into models, which are model A3, model B4 and engine model 5 respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com