Automotive follow-up mileage measuring device

A measuring device and mileage technology, applied in the direction of measuring device, measuring distance, surveying and navigation, etc., can solve problems such as inability to provide stable measurement results, tire wear, vehicle safety hazards, etc., to increase the maximum corner elastic limit function, improve Service life, wear reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

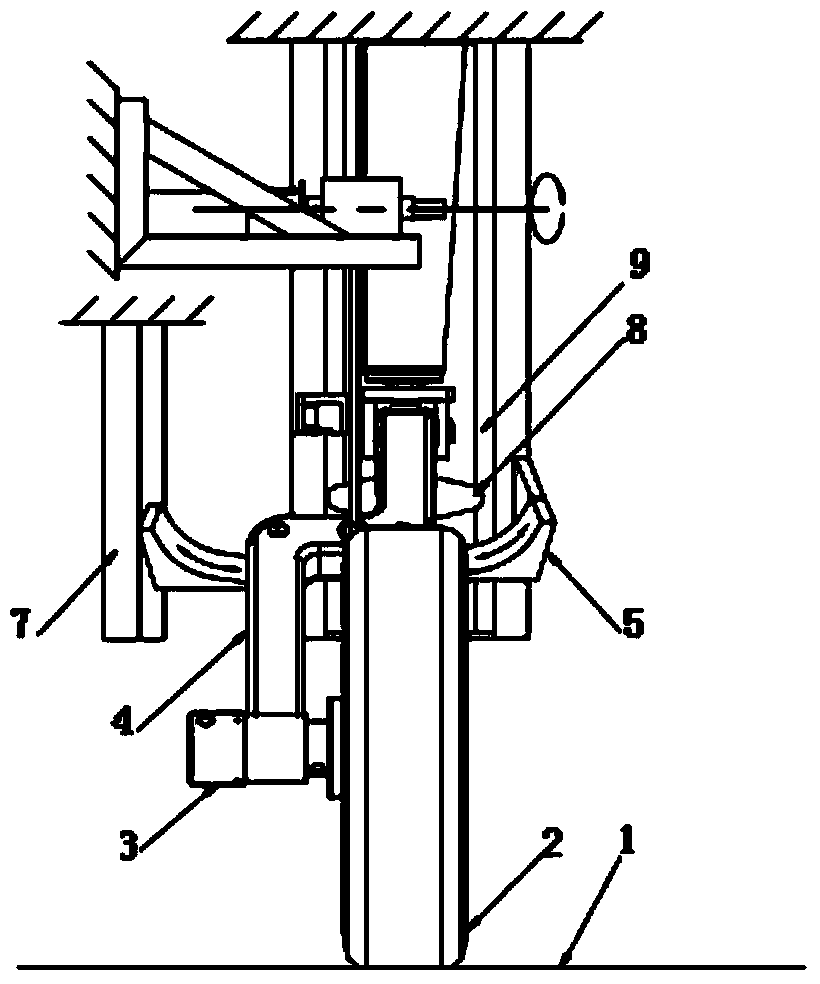

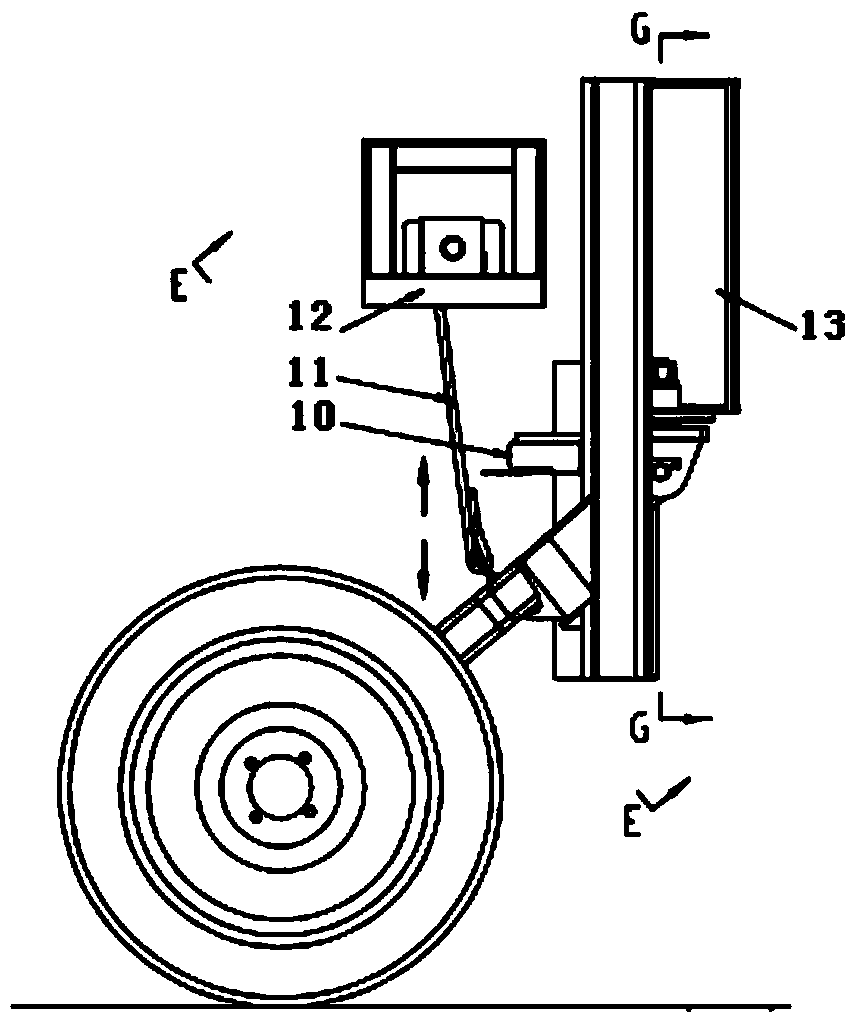

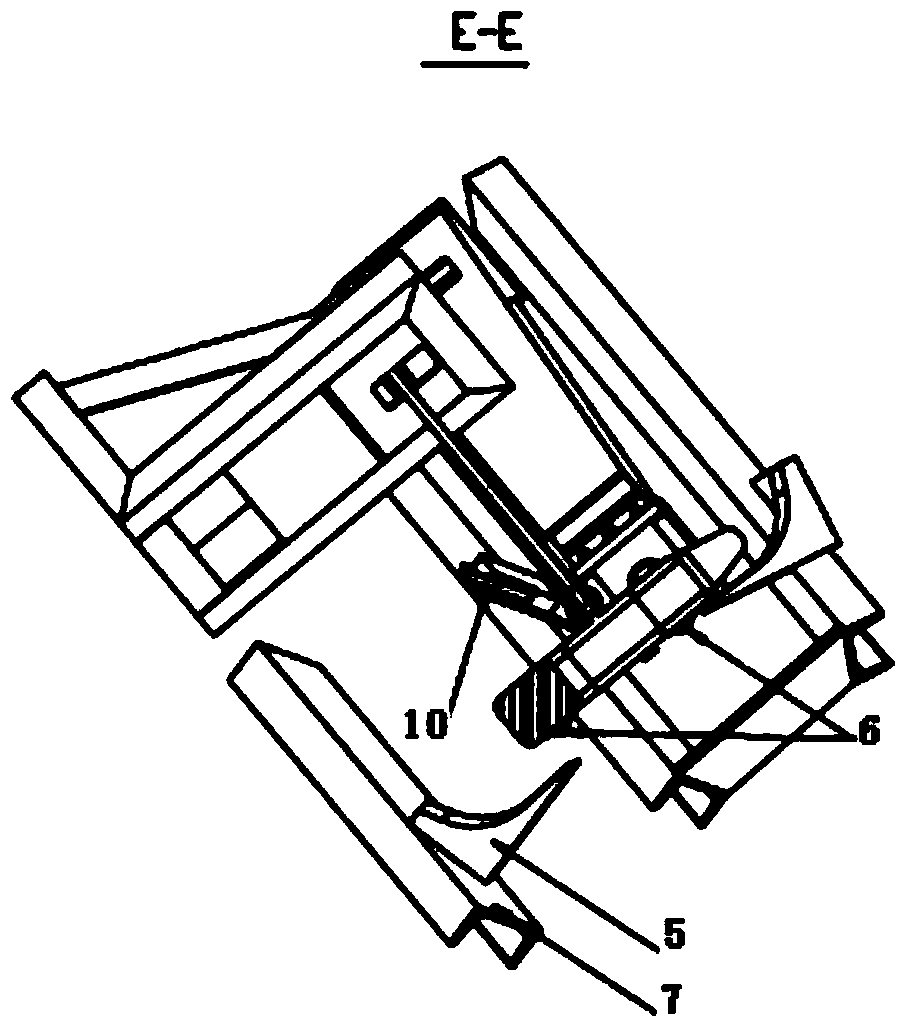

[0028] see Figure 1-4 , shows the vehicle mileage follow-up measuring device of the present invention.

[0029] The vehicle mileage follow-up measuring device of the present invention comprises a measuring wheel 2 capable of contacting the ground 1 , a wheel arm 4 , a wheel arm bracket 14 and a measuring wheel mounting seat 13 .

[0030] Wherein, one end of the wheel arm 4 is provided with a connecting shaft, the measuring wheel 2 is rotatably mounted on the connecting shaft, and an encoder 3 is fixed on the connecting shaft to directly detect the rotation information of the measuring wheel, which can be Optionally, a bearing is provided between the measuring wheel 2 and the connecting shaft.

[0031] The other end of the wheel arm 4 is provided with a shaft hole, and the shaft hole is rotatably fitted on the wheel arm shaft 15 of the wheel arm bracket 14, so that the wheel arm 4 can rotate relative to the wheel arm shaft 15, wherein, A brass bushing 17 can also be press-fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com