Mine Ultrasonic Pipeline Flow Measuring Device and Measuring Method

A flow measuring device, ultrasonic technology, applied in the direction of measuring device, measuring flow/mass flow, liquid/fluid solid measurement, etc., can solve the problems of large number of components, high price, complicated debugging, etc., and achieve simple and convenient operation and low power consumption The effect of low and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

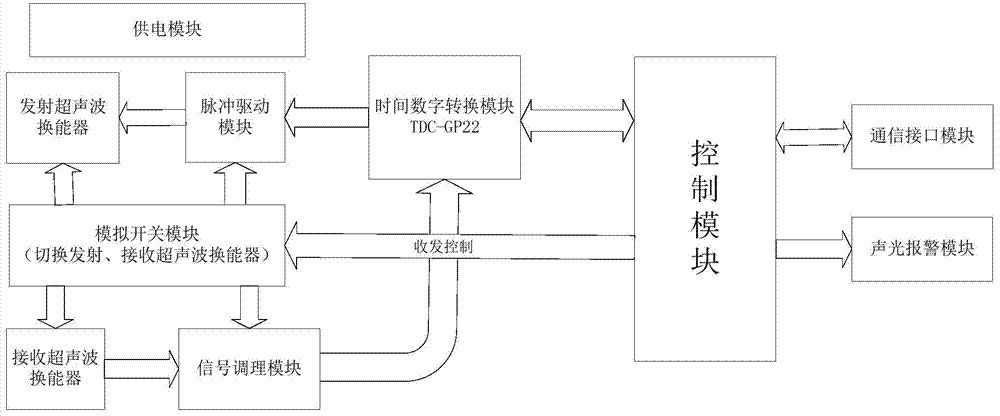

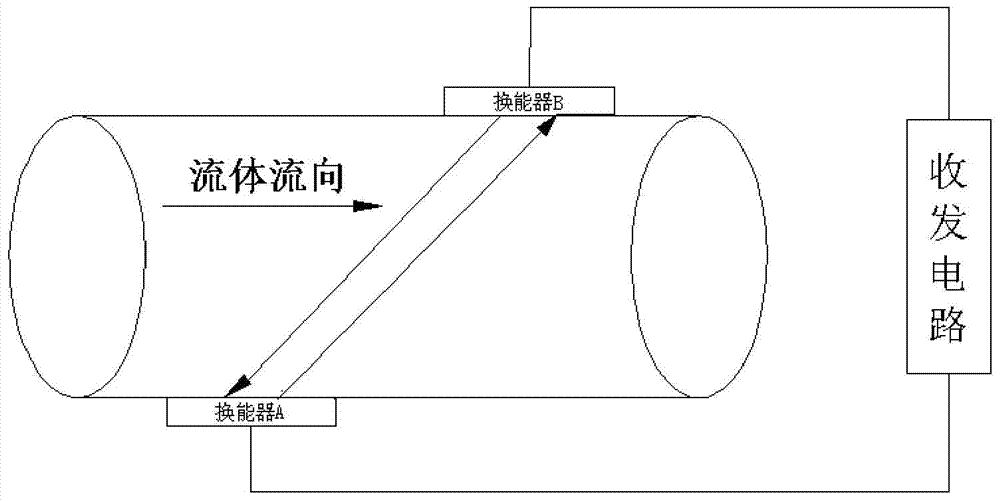

[0027] combine figure 1 As shown, the mining ultrasonic pipeline flow measurement device includes a control module, a time-to-digital conversion module, a pulse drive module, a transmitting ultrasonic transducer, a receiving ultrasonic transducer, an analog switch module, a signal conditioning module, a communication interface module and a power supply Module, preferably, the power supply module adopts 24V intrinsically safe power supply.

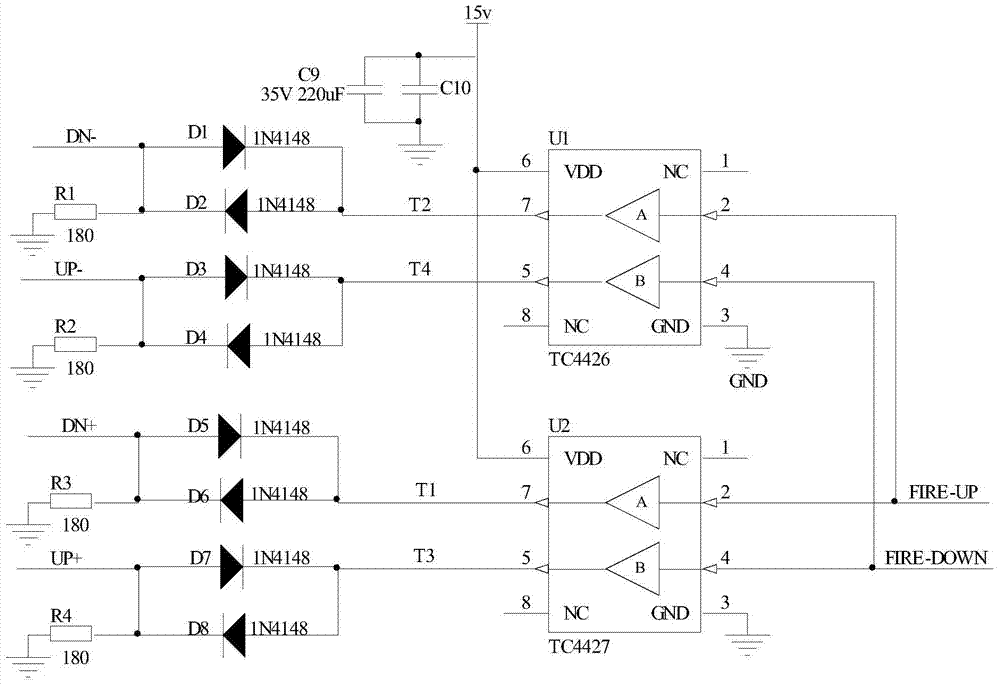

[0028] The control module is connected to the time digital module TDC-GP22 through the SPI bus, the time digital conversion module is connected to the pulse drive module, and the output end of the pulse drive module is connected to the ultrasonic transducer. The analog switch module is respectively connected with the transmitting ultrasonic transducer and the receiving ultrasonic transducer, and the control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com