Small pipeline gas-liquid two-phase flow phase distribution optical detection system and method

A gas-liquid two-phase flow and phase distribution technology, which is applied in the direction of using optical devices, material analysis by optical means, measuring devices, etc., can solve problems such as difficulty in implementation, high cost, and affecting the physical properties of working fluids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The system and invention of the present invention will be further described below in conjunction with the drawings.

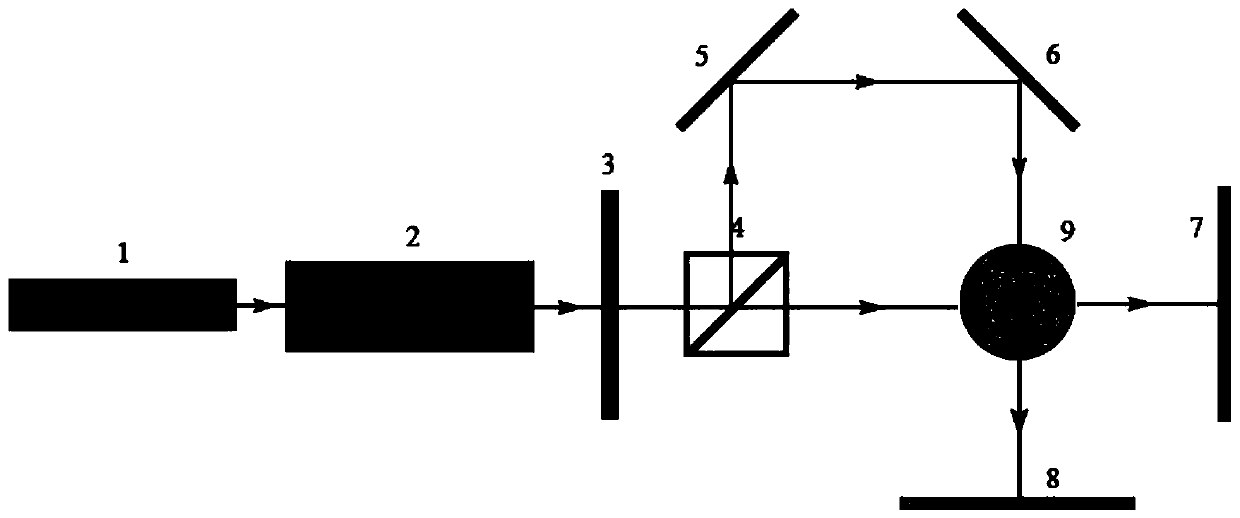

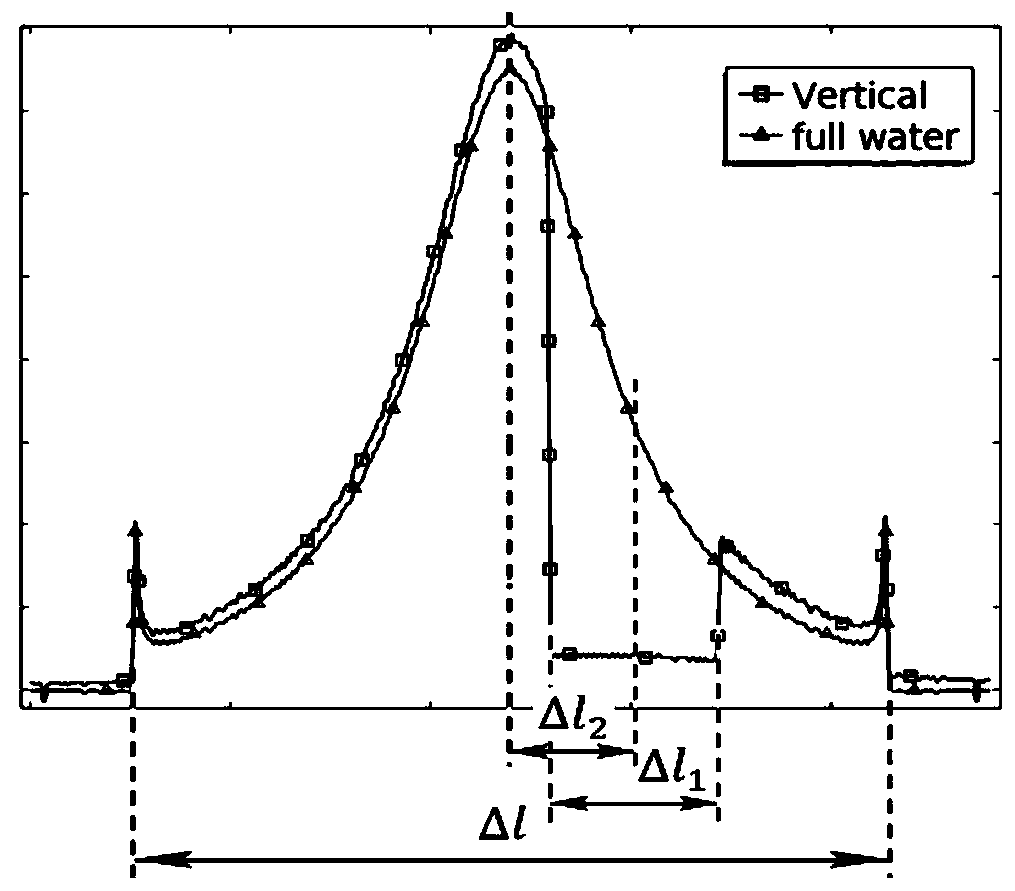

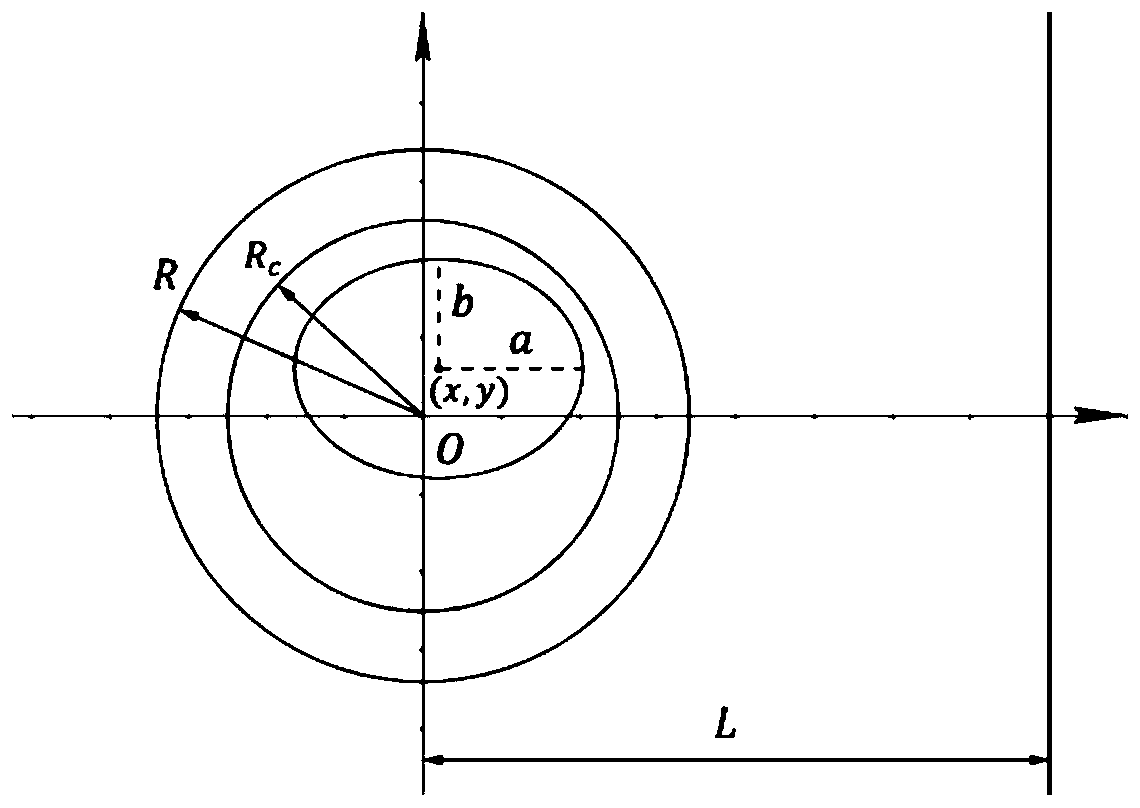

[0054] Such as figure 1 As shown, a small pipeline gas-liquid two-phase flow phase distribution optical detection system consists of laser 1, beam expander 2, slit 3, beam splitter 4, first flat mirror 5, second flat mirror 6, and first high-speed CMOS sensor 7. The second high-speed CMOS sensor 8 and a small pipe gas-liquid two-phase flow 9 are composed. First, the beam emitted by the laser 1 passes through the beam expander 2 and the slit 3 and becomes a parallel sheet beam with a suitable width, which is the same width as the outer diameter of the pipe under test; then, the original parallel sheet beam passes through the beam splitter 4 It is divided into two horizontal and vertical sheet beams. The horizontal beam directly enters the small pipe gas-liquid two-phase flow 9, and the vertical sheet beam is reflected by the first plane mirror 5 and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com