Anti-scouring testing device for road pavement material

A technology of pavement materials and test equipment, applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve problems such as insufficient real data and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

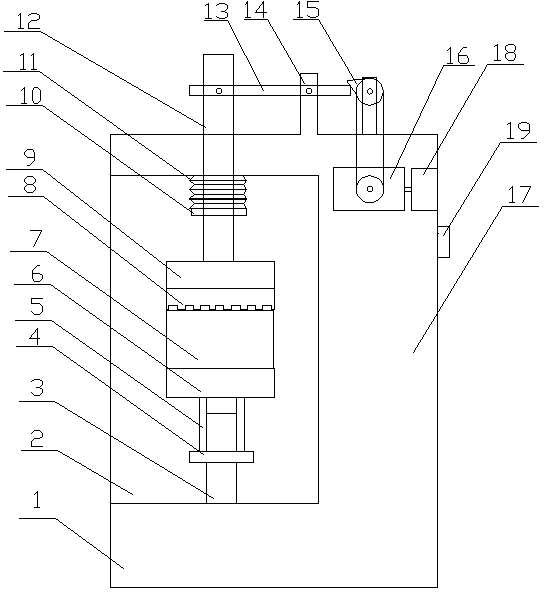

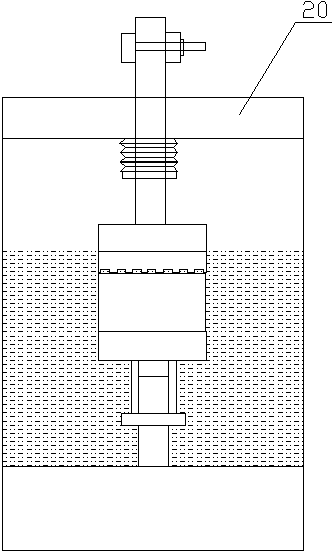

[0022] A kind of anti-scouring test equipment for highway pavement materials, comprising an extrusion mechanism, a tray mechanism, a box body 2, a drive mechanism and a bracket, the box body 2 is arranged in the bracket, and the tray mechanism is connected to the bracket through the box body 2, An extruding mechanism is arranged on the upper part of the support, and the extruding mechanism is connected with the driving mechanism.

[0023] The tray mechanism includes a tray 6 and a lowering strut module. The lowering strut module is arranged on the box body 2. The upper part of the lowering strut module is a tray 6. The lowering strut module includes a screw rod 3 and a threaded pipe 5. And the locking nut 4, the screw rod 3 is fixedly connected with the box body 2, the upper part of the threaded pipe 5 is fixedly connected with the tray 6, and the locking nut 4 is arranged on the screw rod 3.

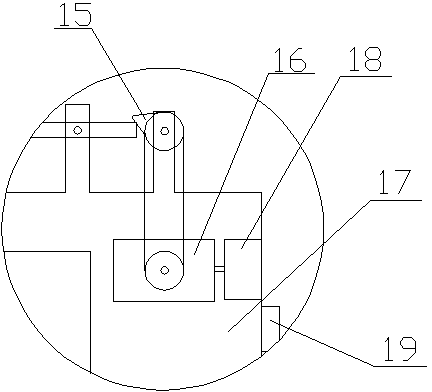

[0024] The extruding mechanism comprises a pressing plate 9, a pressing rod 12, a p...

specific Embodiment 2

[0029] A kind of anti-scouring test equipment for highway pavement materials, comprising an extrusion mechanism, a tray mechanism, a box body 2, a drive mechanism and a bracket, the box body 2 is arranged in the bracket, and the tray mechanism is connected to the bracket through the box body 2, An extruding mechanism is arranged on the upper part of the support, and the extruding mechanism is connected with the driving mechanism.

[0030]The tray mechanism includes a tray 6 and a lowering strut module. The lowering strut module is arranged on the box body 2. The upper part of the lowering strut module is a tray 6. The lowering strut module includes a screw rod 3 and a threaded pipe 5. And the locking nut 4, the screw rod 3 is fixedly connected with the box body 2, the upper part of the threaded pipe 5 is fixedly connected with the tray 6, and the locking nut 4 is arranged on the screw rod 3.

[0031] The extruding mechanism comprises a pressing plate 9, a pressing rod 12, a pr...

specific Embodiment 3

[0034] A kind of anti-scouring test equipment for highway pavement materials, comprising an extrusion mechanism, a tray mechanism, a box body 2, a drive mechanism and a bracket, the box body 2 is arranged in the bracket, and the tray mechanism is connected to the bracket through the box body 2, An extruding mechanism is arranged on the upper part of the support, and the extruding mechanism is connected with the driving mechanism.

[0035] The tray mechanism includes a tray 6 and a lowering strut module. The lowering strut module is arranged on the box body 2. The upper part of the lowering strut module is a tray 6. The lowering strut module includes a screw rod 3 and a threaded pipe 5. And the locking nut 4, the screw rod 3 is fixedly connected with the box body 2, the upper part of the threaded pipe 5 is fixedly connected with the tray 6, and the locking nut 4 is arranged on the screw rod 3.

[0036] The extruding mechanism comprises a pressing plate 9, a pressing rod 12, a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com