Internal over-voltage protection LED driver, internal over-voltage protection LED driving circuit and LED driver working method

A technology of LED driver and overvoltage protection, which is applied in the direction of lamp circuit layout, electric light source, lighting device, etc., can solve problems such as fluctuations, and achieve the effect of simplified peripheral circuits and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

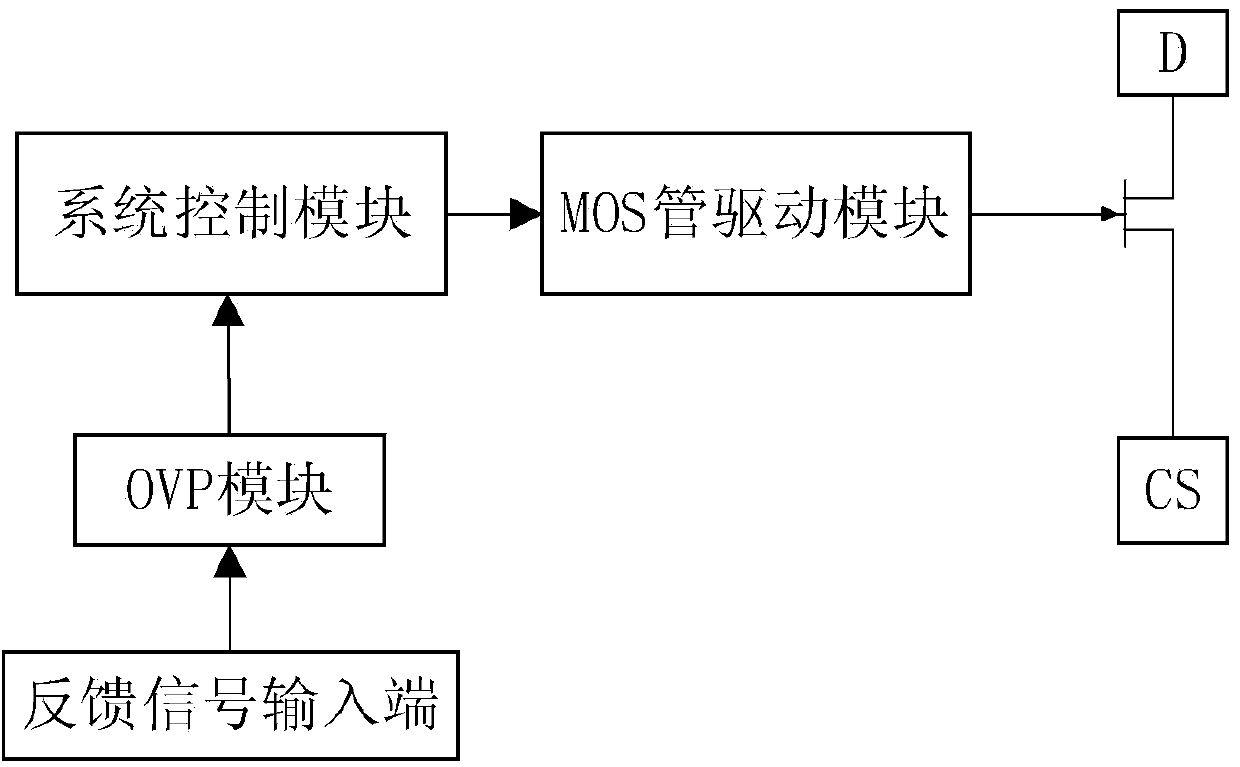

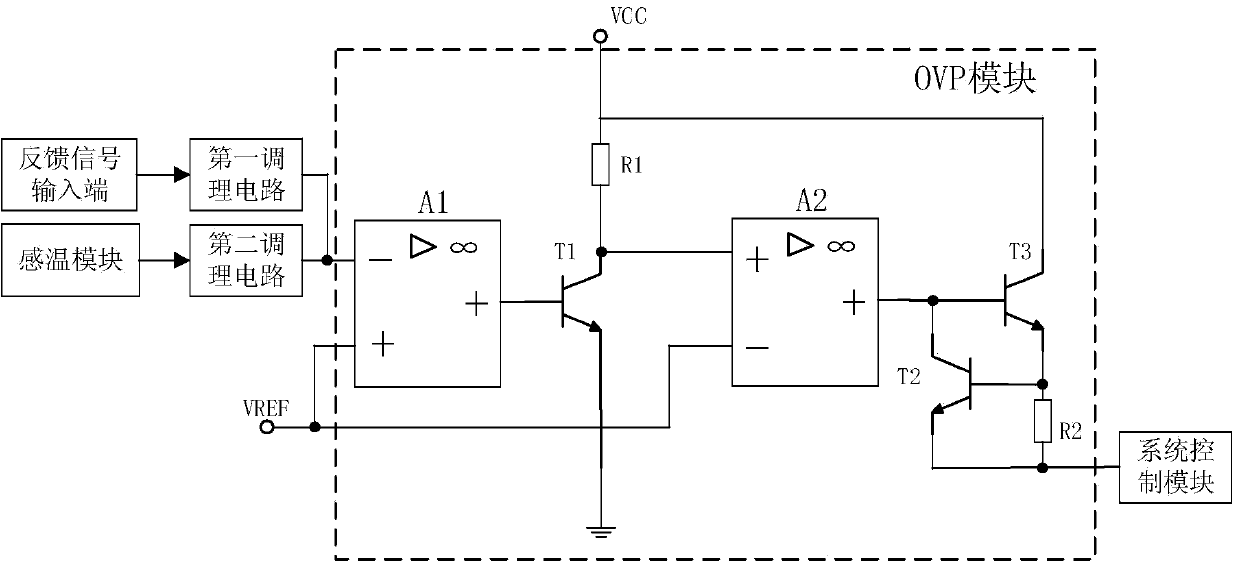

[0025] figure 1 A block diagram of the LED driver is shown.

[0026] Such as figure 1 As shown, an LED driver with built-in overvoltage protection, including:

[0027] The feedback signal input terminal ZCD collects the output voltage of the LED driving circuit formed by the LED driver U1.

[0028] The OVP module judges whether to output an overvoltage protection signal according to the obtained output voltage. Specifically, the output voltage is compared with the overvoltage protection reference voltage UREF, and if the output voltage is greater than the overvoltage protection reference voltage, an overvoltage protection signal is output. The OVP module is an overvoltage protection module.

[0029] A system control module, configured to lock the LED driver according to the overvoltage protection signal.

[0030] Wherein, the system control module can be realized by a microprocessor. It can also be realized by using ST's STM8S series MCU. The locking of the LED driver m...

Embodiment 2

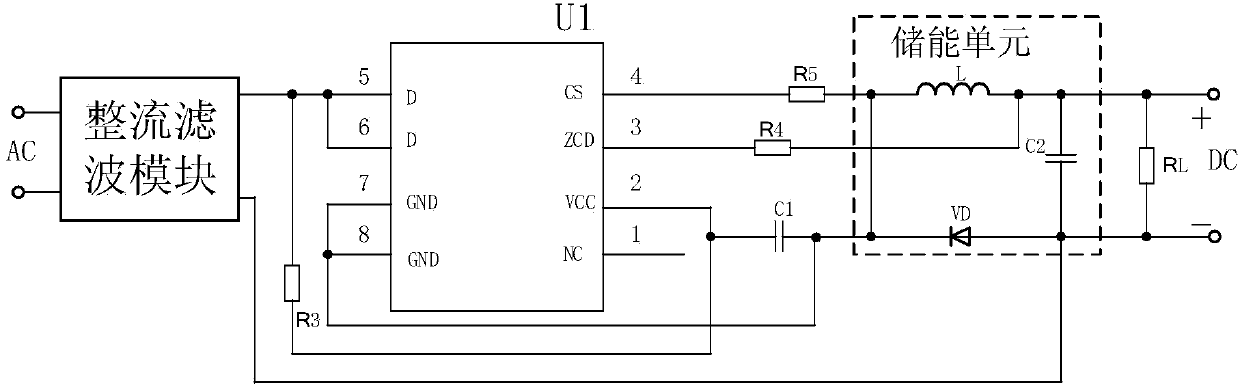

[0037] image 3 A circuit diagram of an LED driving circuit constituted by the LED driver is shown.

[0038] Among them, the pins of the LED driver U1: pin 1 floating, pin 2 power supply, pin 3 feedback signal input terminal, pin 4 MOS tube source, pin 5 and pin MOS tube drain, pin 7 and pin 8 grounding terminal .

[0039] Such as image 3 As shown, in the LED driving circuit composed of the LED driver based on Embodiment 1, the output terminal of the LED driver is connected to the energy storage unit through an output resistor R5, and the output terminal of the energy storage unit is connected through a feedback resistor R4 is connected with the feedback signal input terminal (pin 3).

[0040] Wherein, the energy storage unit includes: an inductor L, a capacitor C2, and a freewheeling tube VD.

[0041] The LED driver realizes the feedback function only through the feedback resistor R4, which is simpler than the circuit of the traditional LED driver circuit and saves hardw...

Embodiment 3

[0043] The working method of the LED driver based on Embodiment 1, the working method includes: an overvoltage protection method, the method includes:

[0044] The OVP module judges whether to output an overvoltage protection signal according to the obtained output voltage; if the output voltage is greater than the overvoltage protection reference voltage UREF, then outputs an overvoltage protection signal, and the system control module outputs the overvoltage protection signal according to the overvoltage protection signal The LED driver is locked out.

[0045] In this embodiment, the specific implementation of the OVP module is the same as that in Embodiment 1, and will not be repeated here.

[0046] Further, the working method also includes: a method for overheating protection, which includes: converting the temperature signal into a voltage signal through a temperature sensing module and then inputting it to the OVP module through a second conditioning circuit, and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com