Power source management driving chip and application circuit thereof

A technology for driving chips and power management, which is applied in the layout of electric lamp circuits, electric light sources, light sources, etc., can solve the problems of inability to use primary side negative feedback, no fixed frequency oscillator, and difficulty in obtaining effective protection, so as to shorten the response time, Cost reduction, high power factor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

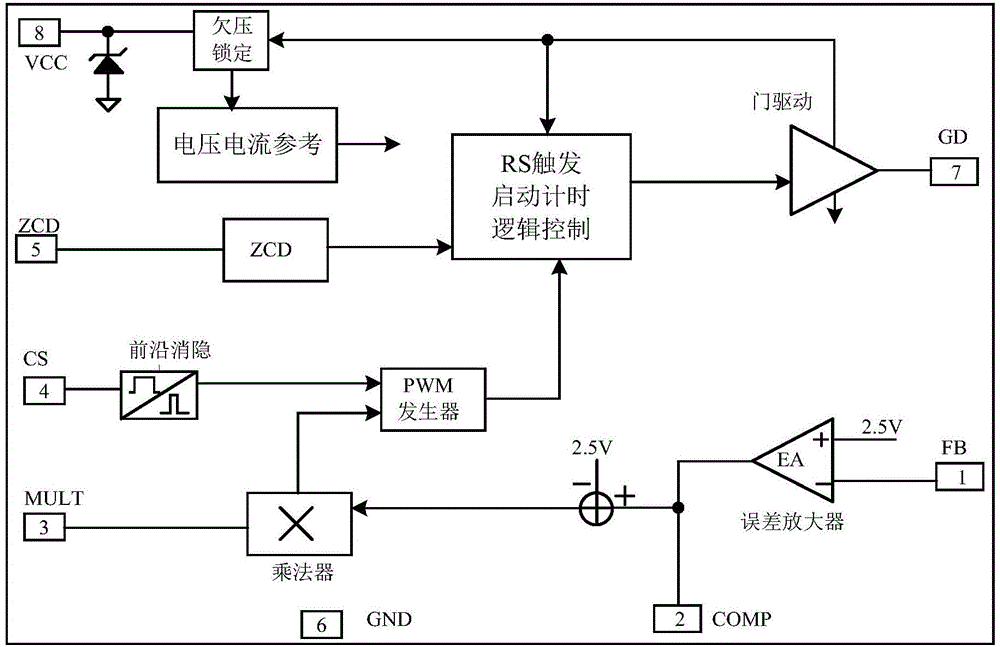

[0046] See Figure 4 , a power management drive chip, which is provided with a power input pin VCC, a ground pin GND, a peak voltage input pin Vmax, a sampling resistor pin Rs, a zero current detection pin ZCD, a current sensing pin CS and a gate driving pin GD, inside the chip It is equipped with V / I converter, delay unit 1, delay unit 2, RS flip-flop, monostable circuit, leading edge blanking circuit, error comparator A1, Schmitt trigger G1, NOT gate G2, follower G3, three-input NAND gate G4, NAND gate G5, NOT gate G6, counter G7, logic control unit G8 and output stage G9, wherein:

[0047] The peak voltage input pin Vmax and the sampling resistor pin Rs are connected to the V / I converter, and the peak voltage signal input by the peak voltage input pin Vmax is converted into a current signal throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com