Method for producing disposable wearable article

A manufacturing method, a one-time technology, applied in medical science, clothing, underwear, etc., can solve the problem of unclear patterns, etc., and achieve the effect of continuous production and high-efficiency production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Hereinafter, the structure of the wearing article 1 which concerns on one Example of this invention is demonstrated based on drawing.

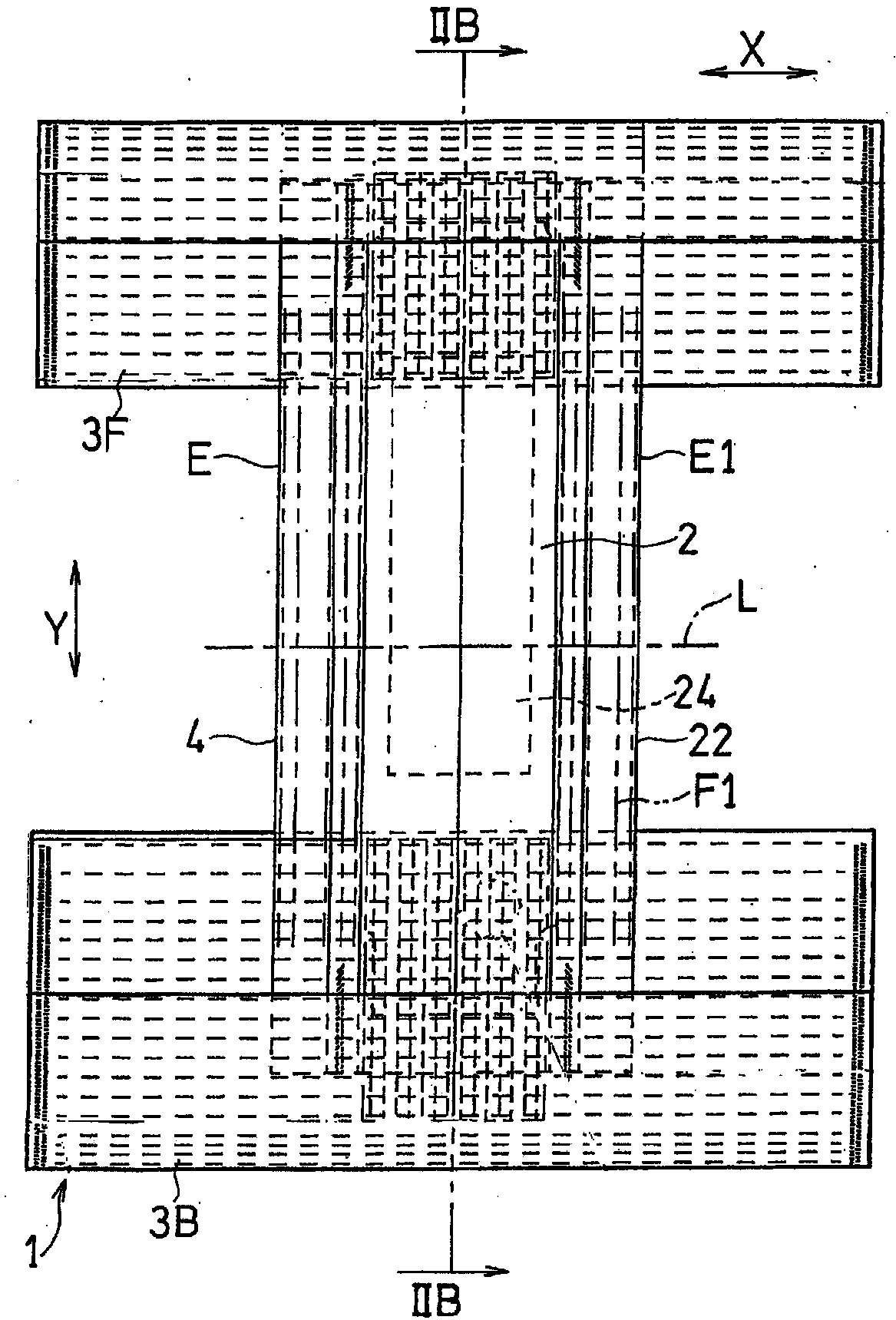

[0053] Figure 1 to Figure 7 Example 1 is shown.

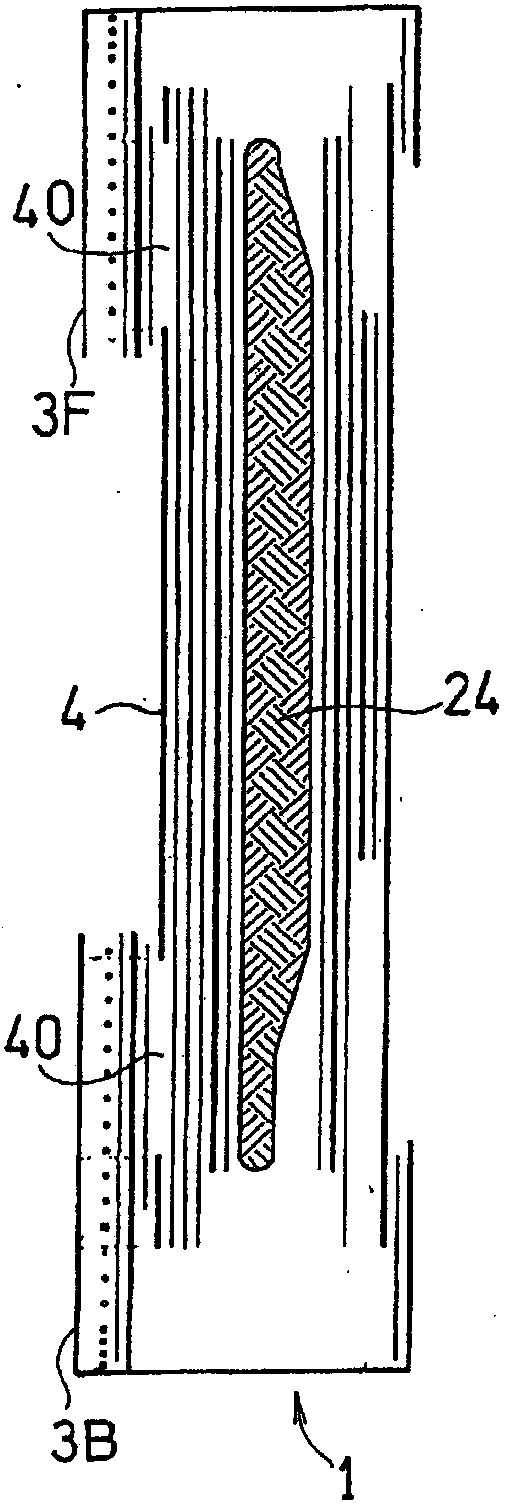

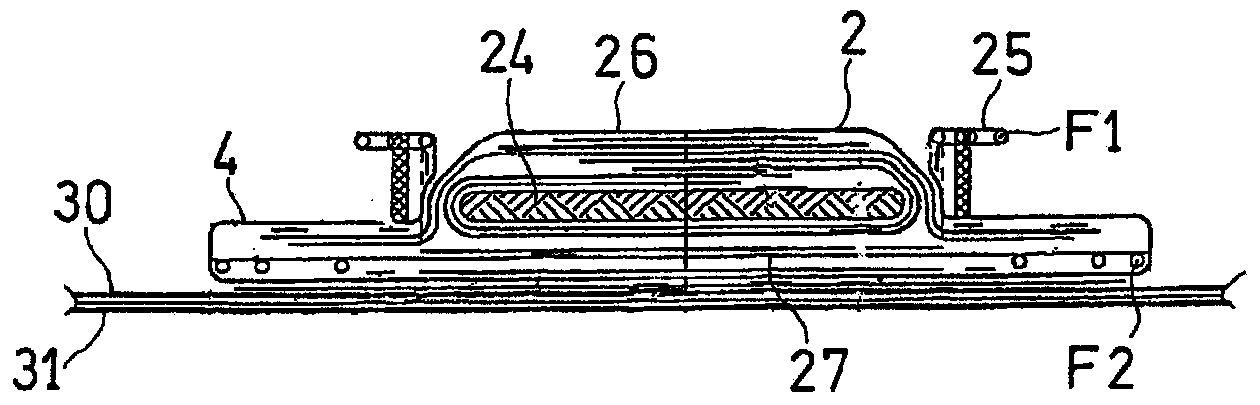

[0054] Such as figure 1 as well as Figure 2A As shown, the wearing article 1 of this embodiment includes an absorbent main body 2, a front waist member 3F, and a rear waist member 3B. The absorbent main body 2 has a front portion (front waist portion) 20 covering the front body of the wearer and extending in the waist direction X, and a rear portion (rear waist portion) covering the rear body of the wearer and extending in the waist direction X. ) 21, and the crotch portion 22 covering the crotch between the front portion 20 and the rear portion 21.

[0055] The crotch portion 22 is connected to the front portion 20 and the rear portion 21 and extends along a longitudinal direction Y perpendicular to the waist direction X. The absorbent main body 2 constitutes part or all of the c...

Embodiment 2

[0099] Figure 9 ~ Figure 13 Example 2 is shown. Hereinafter, the difference between Example 2 and Main Example 1 will be mainly described.

[0100] In the first embodiment, the periphery of the notch 40 is completely surrounded by the outer non-woven fabric 4, but in Figure 9 as well as Figure 10 In this embodiment, the periphery of the notch 40 is not completely surrounded by the exterior nonwoven fabric 4 .

[0101] Such as Figure 10 As shown, the outer nonwoven fabric 4 is formed with a notch 40 that is depressed from the end in the longitudinal direction Y toward the center. End edges of the exterior nonwoven fabric 4 in the longitudinal direction Y are not connected in the waist direction X, but are separated from each other in the waist direction X via the notch 40 .

[0102] That is, both ends of the notch 40 in the waist direction X are defined by the exterior nonwoven fabric 4, and the longitudinal direction Y of the notch 40 is defined by the exterior nonwov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com