Device for hydrodynamically strengthening nonwovens, wovens or knitted fabrics

A kind of non-woven fabric, knitted fabric technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

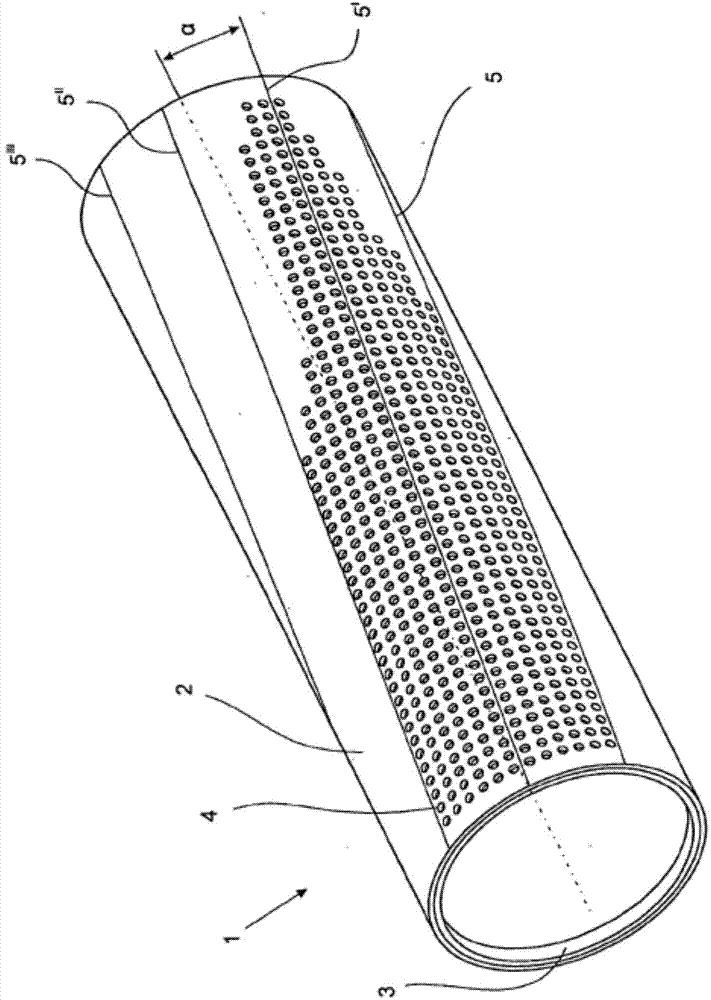

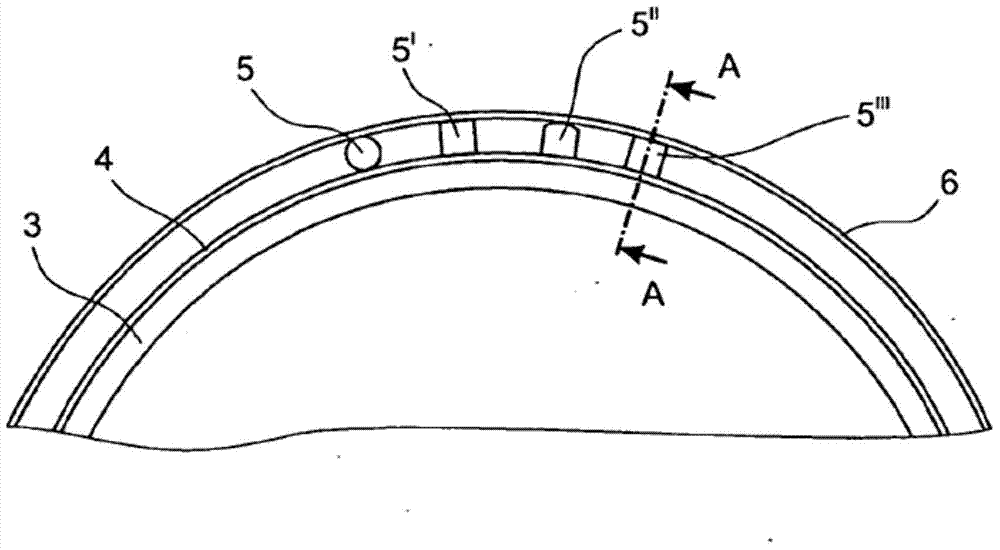

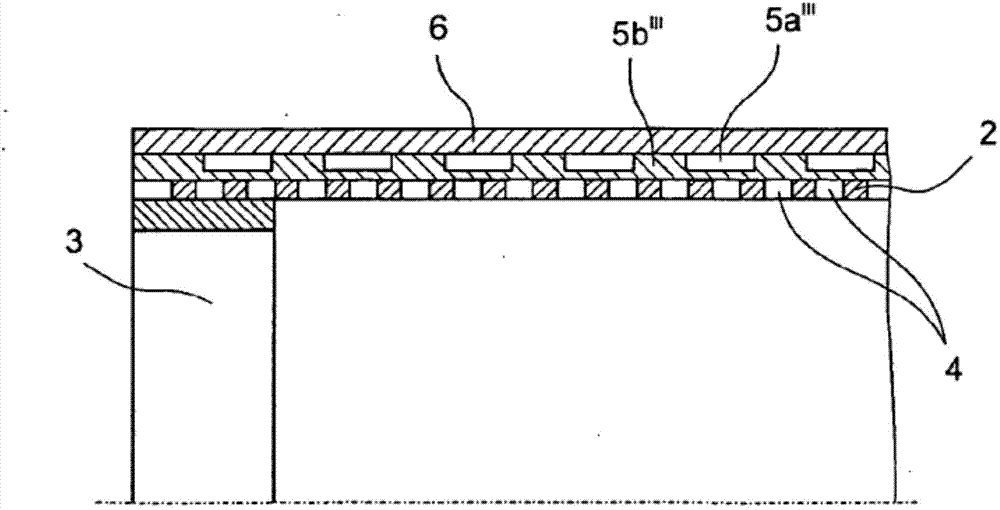

[0032] exist figure 1 A base cylinder 1 is shown in , which has a plurality of holes 4 on its surface. The basic drum 1 can be designed as a solid cylindrical component or as a component with a plurality of cylindrical supports 3 on which a sheet metal 2 or a fabric with a plurality of holes 4 is stretched. In this exemplary embodiment, the sheet metal 2 is stretched on two cylindrical supports 3 , of which only the supports 3 are shown. The support 3 is arranged in the region of the end faces of the base drum 1 and is designed to receive bearing parts (not shown) on both sides. The wall thickness of the solid base cylinder 1 can be between 2 mm and 10 mm. In the case of thin plates 2, the wall thickness can be between 1 mm and 6 mm.

[0033]The bore 4 is generally cylindrical and can have a diameter of 2 mm to 10 mm, preferably 3.5 mm to 5 mm. The contour of the hole 4 can have an oval, square or other shape. Furthermore, the cross-section of the holes 4 can vary over th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com