Plated plastic case

A technology of plastic casing and reinforced plastic, which is applied in the fields of casing/cabinet/drawer parts, liquid chemical plating, metal material coating process, etc. It can solve the problem that the safety guarantee cannot be said to be sufficient, and the orientation is not considered. Problems such as the internal casing of electrical products, to achieve the effect of simplifying the assembly process and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

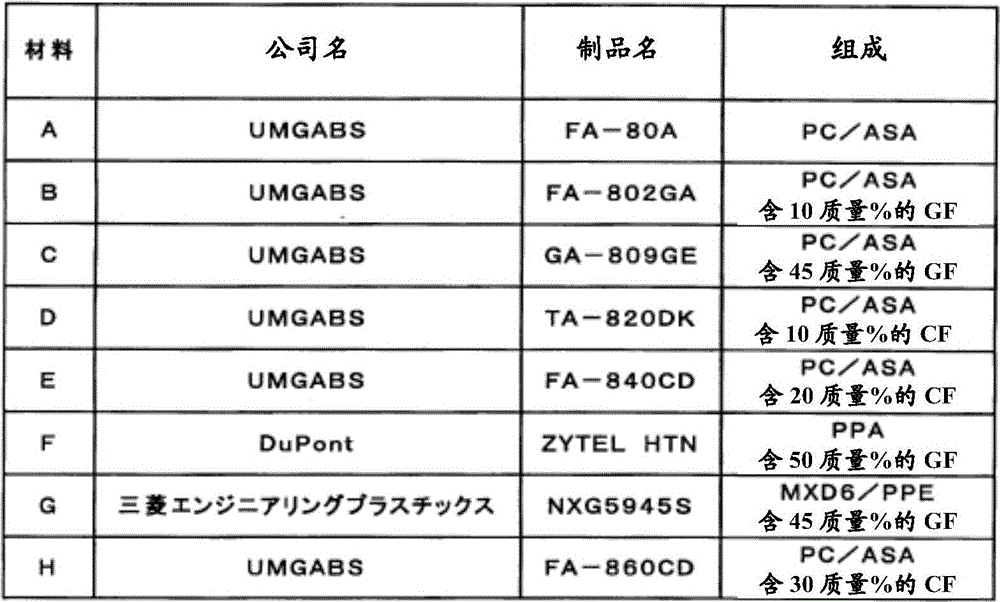

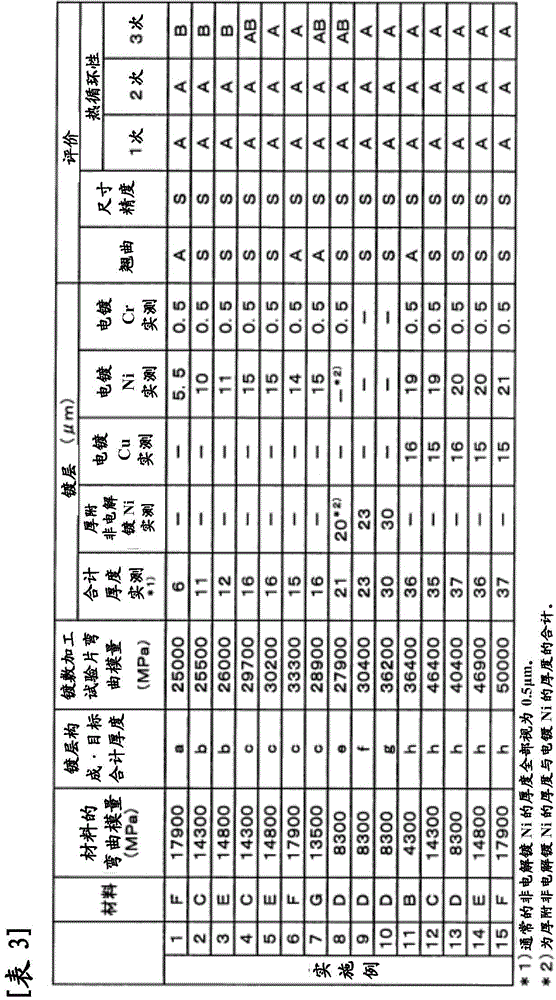

[0187] (flexural modulus of filler-reinforced plastics)

[0188] Using an injection molding machine, material F was molded into a test piece having a thickness of 12.5 mm×127 mm×4 mm. The bending modulus was measured about the said test piece. The results are shown in Table 3.

[0189] (Flexural modulus of plated test piece)

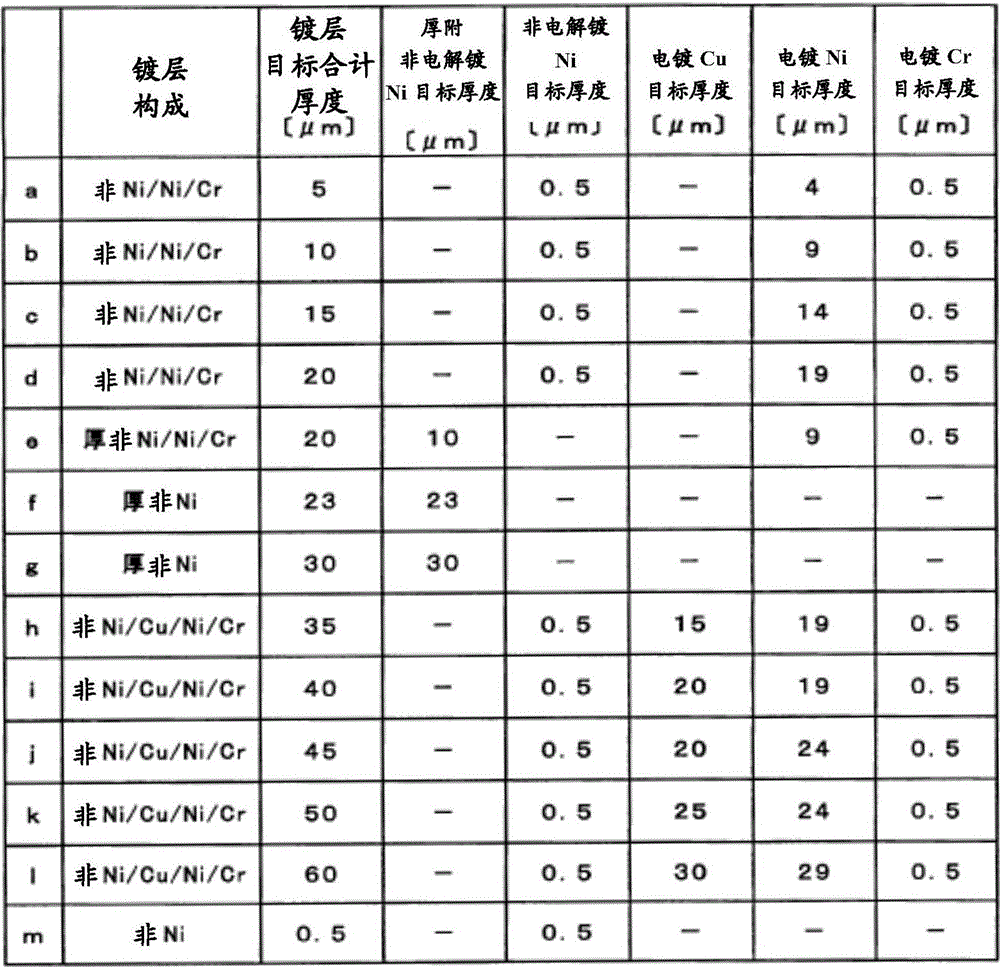

[0190] Using an injection molding machine, the material F was molded into a test piece having a thickness of 12.5 mm×127 mm×1 mm, and a plated layer was formed with the structure shown in Table 2 and the target total thickness a to obtain a plated test piece.

[0191] The bending modulus was measured about the said plating processing test piece. The results are shown in Table 3.

[0192] (plated plastic case)

[0193] Using an injection molding machine, material F was molded into a plastic case main body (internal case test piece for mobile equipment) with a thickness of 80 mm x 125 mm x 1.5 mm, and a plating layer was formed with the composition sh...

Embodiment 2~25

[0194] [Examples 2-25, Comparative Examples 1-5]

[0195]The material F was changed to the materials shown in Tables 3 and 4, and the composition of the plating layer and the target total thickness a were changed to the structures and target total thicknesses shown in Tables 3 and 4, and the test was obtained in the same manner as in Example 1. Sheets, plated test pieces and plated plastic casings. The results are shown in Tables 3 and 4.

[0196]

[0197]

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com