A thermal device and method for increasing the temperature of boiler wet desulfurization net flue gas

A wet desulfurization and thermal device technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as consumption of high-quality fuel, damage to anti-abrasion materials of flue and chimney inner wall, and insufficient power for air flow to rise. , to reduce anti-corrosion and maintenance costs, avoid acid droplet sedimentation, and prevent the effect of air velocity drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

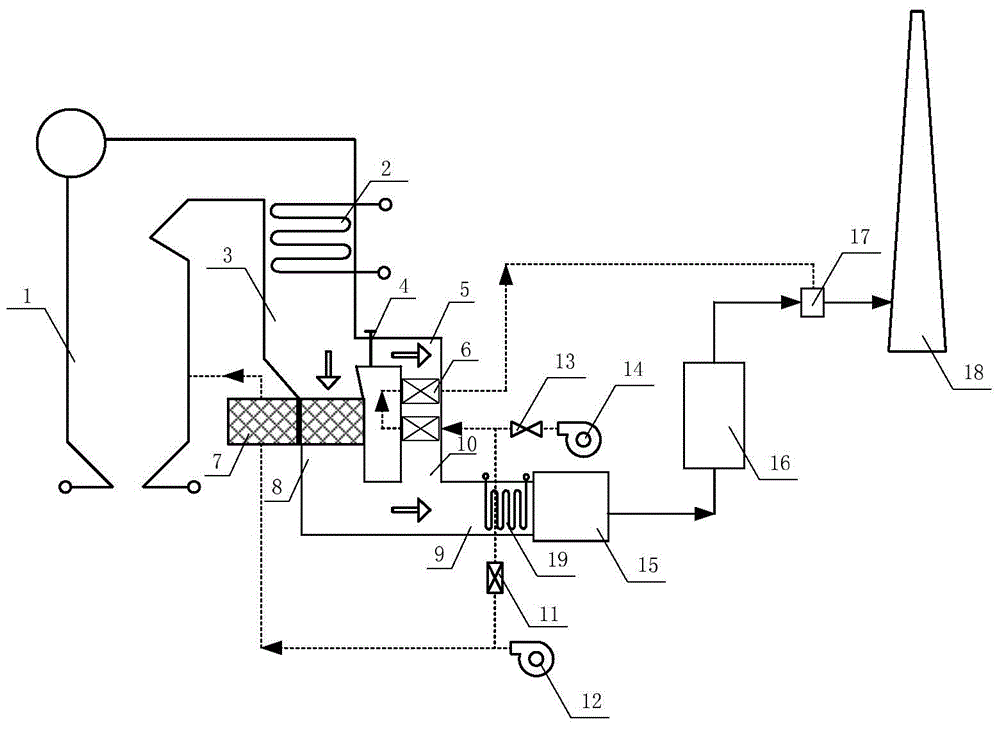

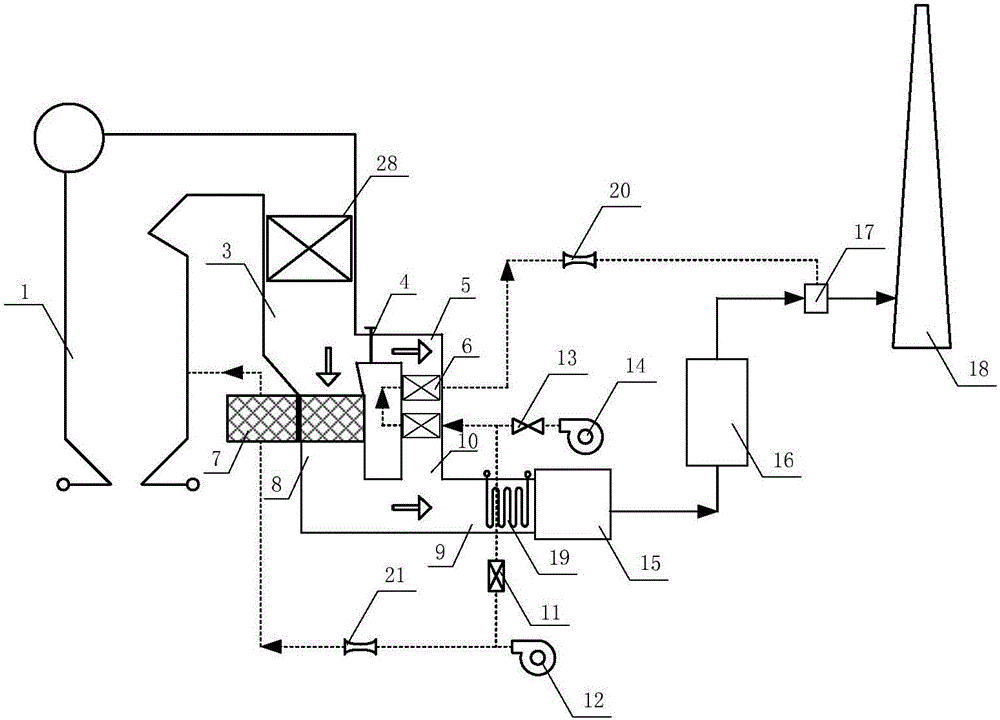

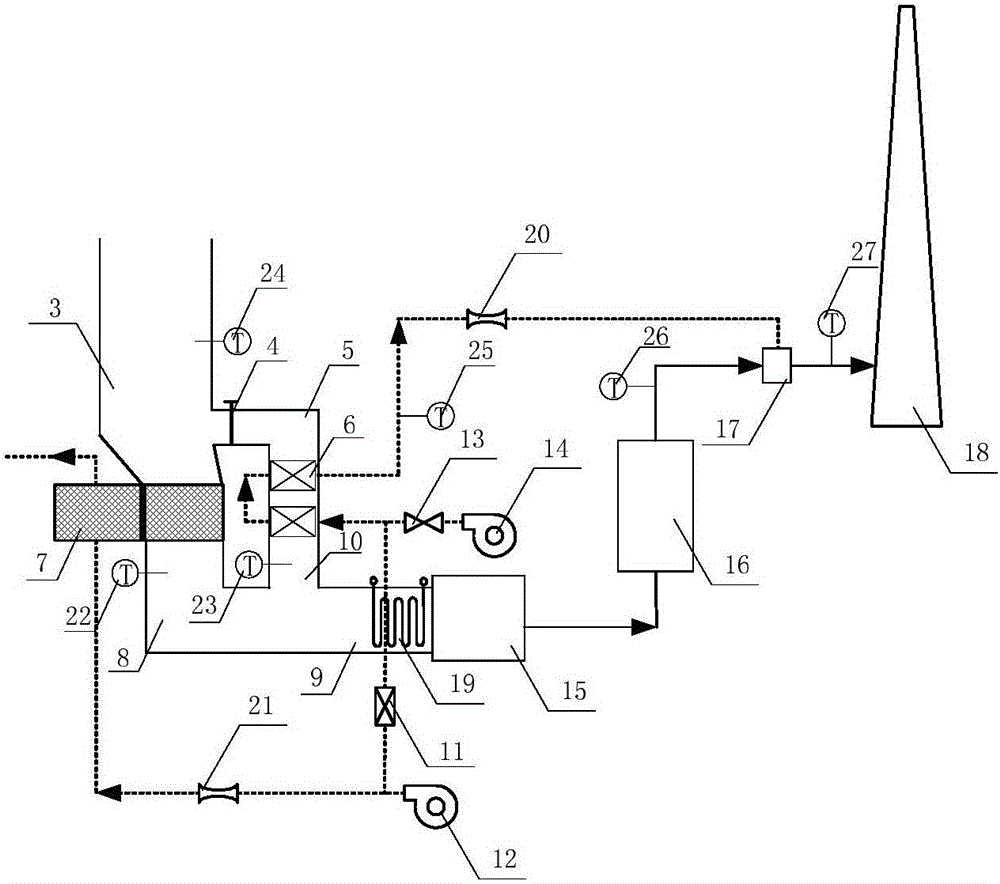

[0039] figure 1 It is a schematic diagram of the thermal device and method (boiler without SCR device) for improving the net flue gas temperature of the present invention; figure 2 It is a schematic diagram of the thermal device and method (boiler with SCR device) for improving the net flue gas temperature of the present invention; image 3 It is a schematic diagram of the thermal measurement and control of the thermal device and method for increasing the net flue gas temperature of the present invention.

[0040] The thermal device for improving the temperature of boiler wet desulfurization net flue gas proposed by the present invention includes: a boiler body, a tail flue gas treatment device and a net flue gas heating device, wherein the tail flue gas treatment device includes a dust collector and a wet desulfurization device, The boiler flue gas passes through the wet desulfurization device to obtain clean flue gas, and the clean flue gas is heated by the clean flue gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com