Saw sharpener

A filing and sawing machine and saw blade technology, which is applied in the field of grinding equipment, can solve problems such as unfavorable long-term use, low efficiency, and easy misoperation, and achieve the effect of improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

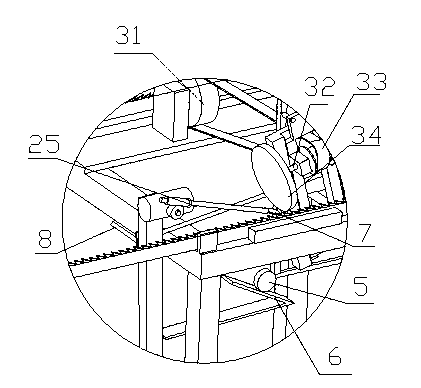

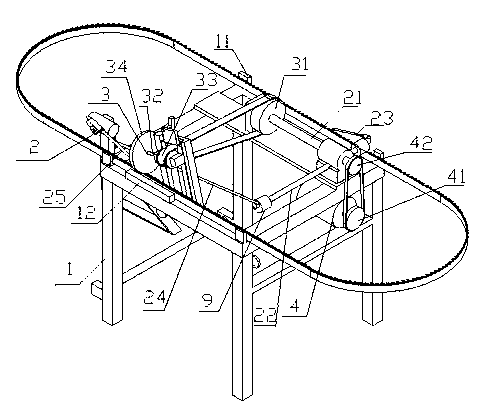

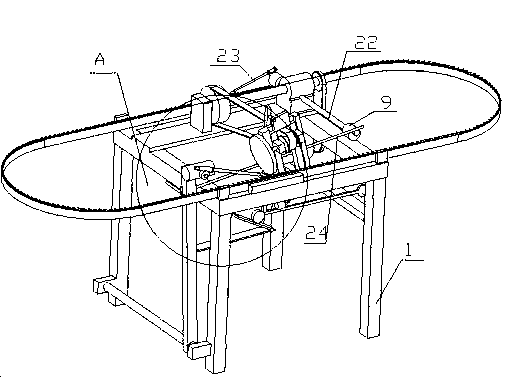

[0029] Example 1, such as figure 1 , figure 2 and image 3Shown: a filing and sawing machine, including a frame 1, this kind of filing and sawing machine includes a propelling device 2 for moving the saw blade on the frame 1, a grinding device 3 for grinding the saw teeth of the saw blade, and a grinding device 3 for the propelling device 2 and the grinding The motor 4 that device 3 provides power; Motor 4 is connected with runner one 41, and runner one 41 is connected with runner two 42 by belt, and propulsion device comprises the transmission shaft one 21 that is connected at runner two 42 circle center positions, and transmission shaft One 21 is vertically connected to the transmission shaft two 22 driven by the transmission shaft one 21 to rotate, and the push bar one 23 that is connected to the off-axis center position of one end of the transmission shaft two 22 and conflicts with the saw blade is connected to the other end of the transmission shaft two 22 off-axis The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com