Manufacturing method of storage chair

A manufacturing method and inverted trapezoidal technology, which are applied in the direction of manufacturing tools, wood processing appliances, etc., can solve the problems of unsuitable placement of irregularly shaped objects and small storage volume, and achieve simple product structure, improved storage volume, and simple manufacturing method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

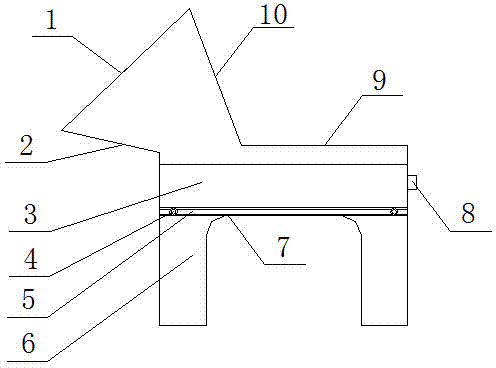

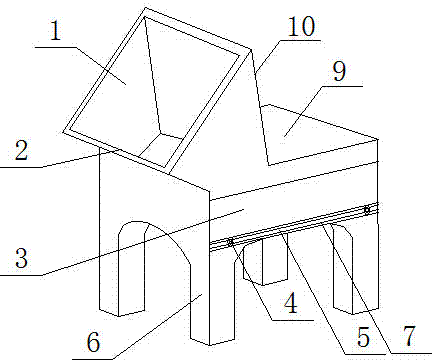

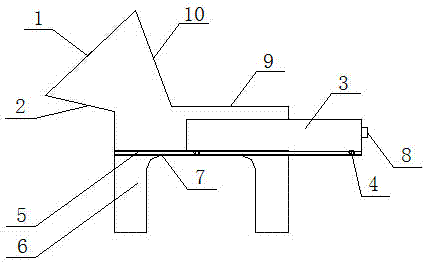

[0021] The present invention will be described below in conjunction with the accompanying drawings. figure 1 It is a structural schematic diagram of the present invention, figure 2 is a perspective view of the present invention, image 3 It is the use status diagram of the present invention.

[0022] A kind of manufacturing method of receiving chair of the present invention, wherein, comprise the following steps: A, select inverted trapezoidal cube structure wood block, use planer, hollow out the middle of inverted trapezoidal cube wood block, form inverted trapezoidal lumen structure, Make the bottom surface an opening structure of 40cm*40cm, make the upper opening an opening of 50cm*50cm, and make the upper opening penetrate the lower opening, choose a piece of wood with a length of 60cm, a width of 50cm, and a thickness of 5cm, and use a chisel planer on one end of the board , cut out a hole of 40cm*40cm, the other end of the plank is polished with a polishing machine to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com