Method for designing chain without welding spot and riveting spot

A design method and technology without solder joints, applied in the direction of metal chains, belts/chains/gears, transmission chains, etc., can solve the problems of difficult process, metal chain failure, cost increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

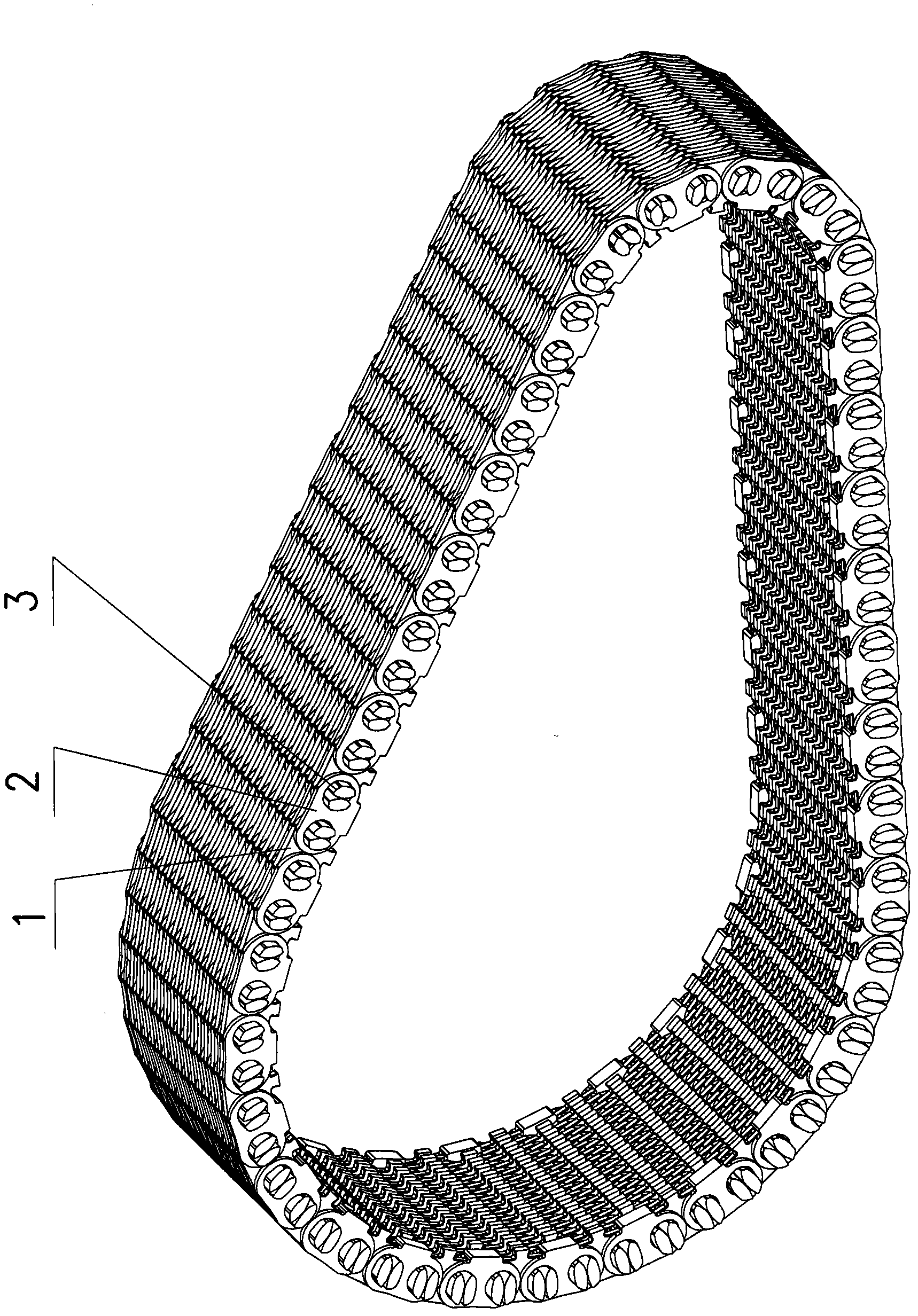

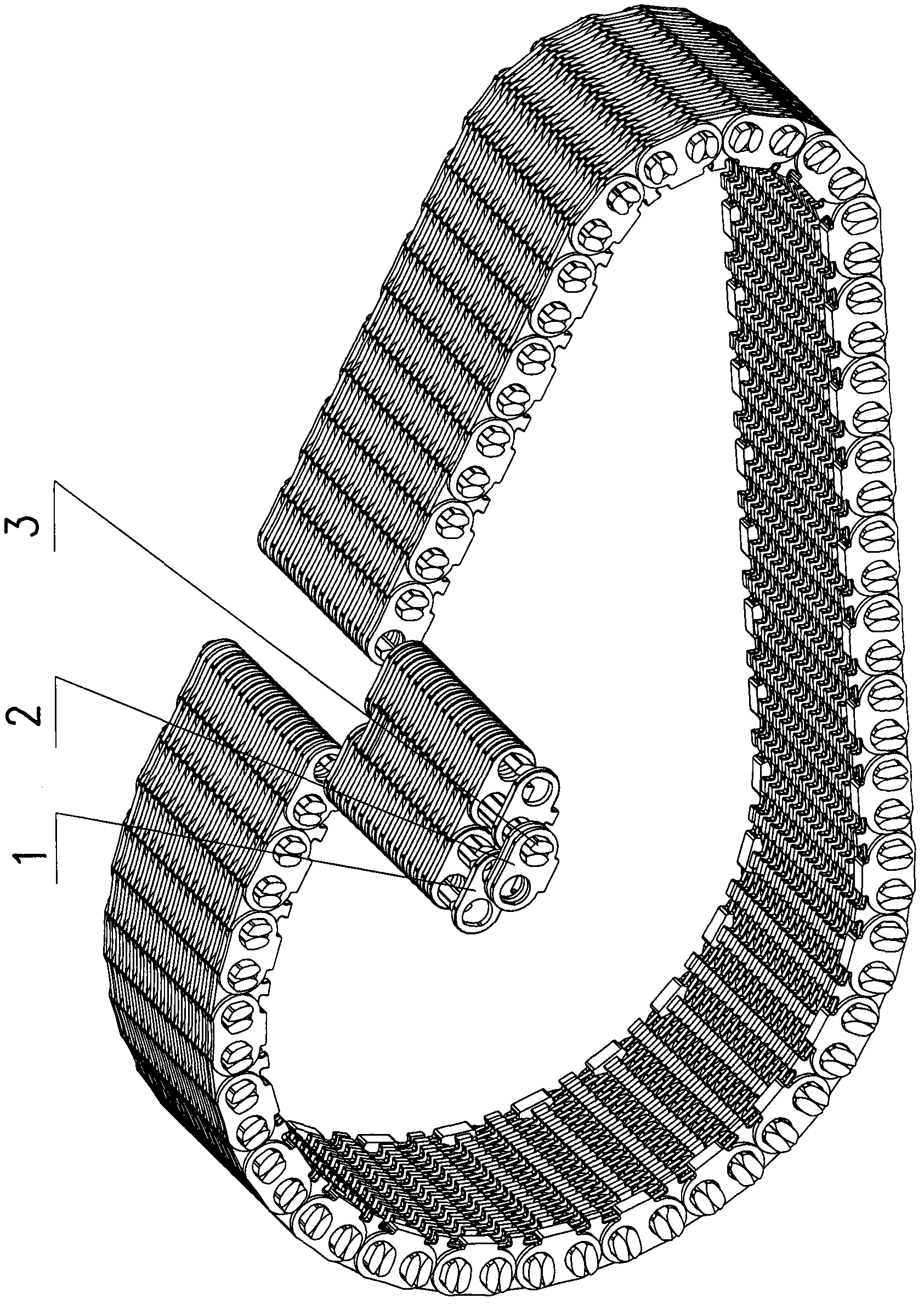

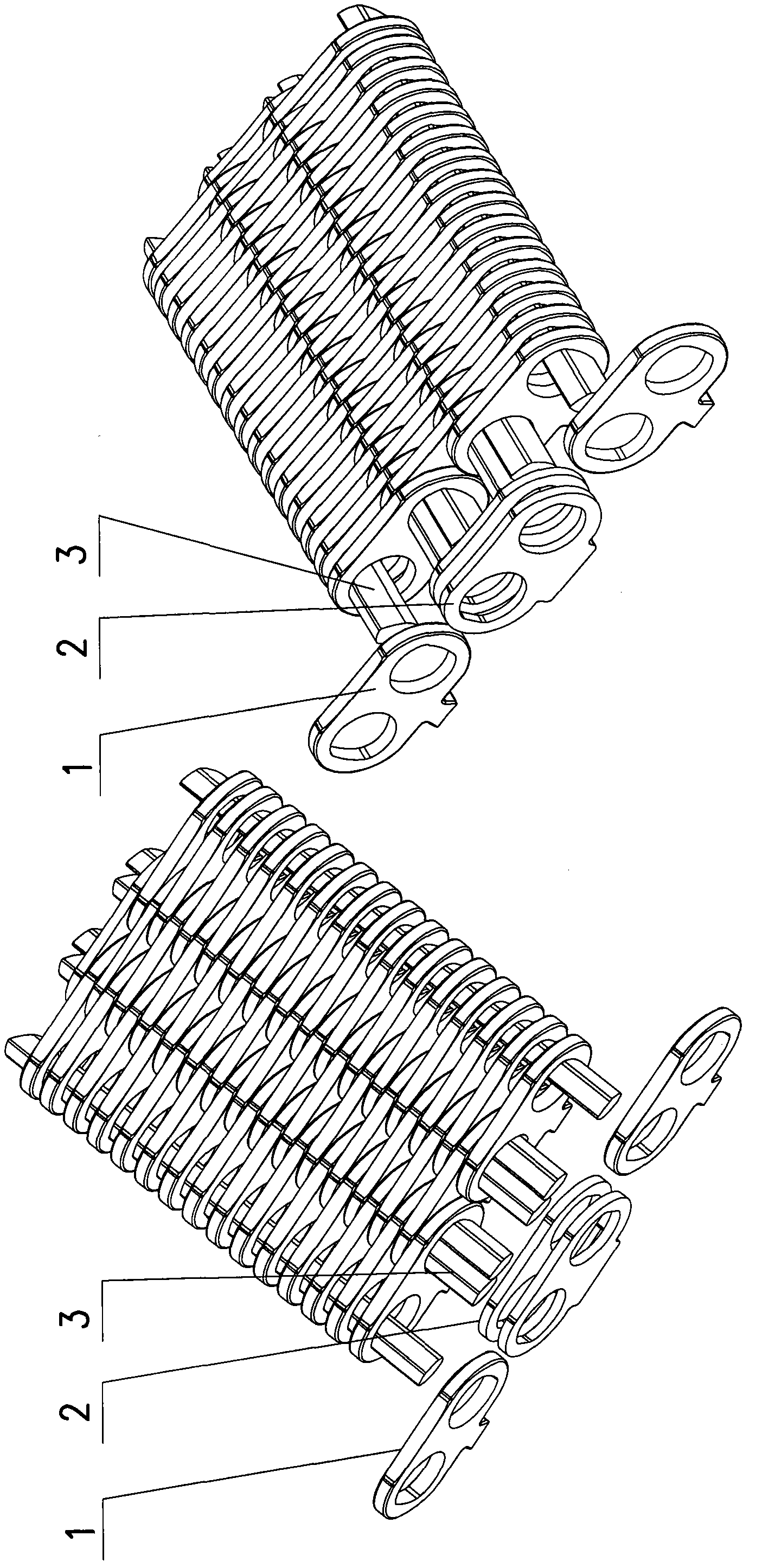

[0013] combine Figure 1 to Figure 6 According to the structural description, we can clearly see the design method of the chain without solder joints and riveting points. The chain is composed of: constraint chain piece, transmission chain piece and pin shaft. It is characterized in that the outer chain piece and pin of the traditional chain are cancelled. The welding or riveting process between the shafts uses special restraint chain pieces and transmission chain pieces to alternately overlap and assemble at intervals on both sides of the chain, so that the outer sides of the entire chain can be integrated into one body and play a role in the axial direction of the outer chain pieces. Constraint.

[0014] For the chain type continuously variable transmission, since the whole chain is assembled by alternately lapping the restraining chain and the transmission chain to connect the two outer chains into one, all the chains in the wrap angle area are clamped by two cone discs for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com