Silicon steel mechanical scoring machine

A scoring machine and mechanical technology, applied in the field of iron and steel metallurgy, can solve the problems of silicon steel slipping, inconvenience, affecting the processing quality, etc., and achieve the effects of weakening lateral force, improving stability and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

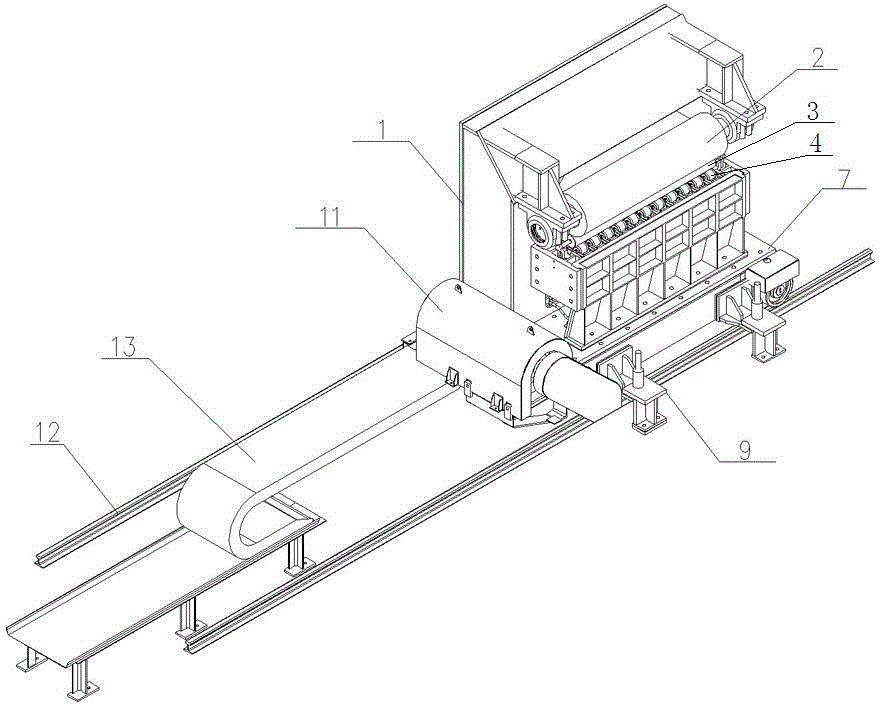

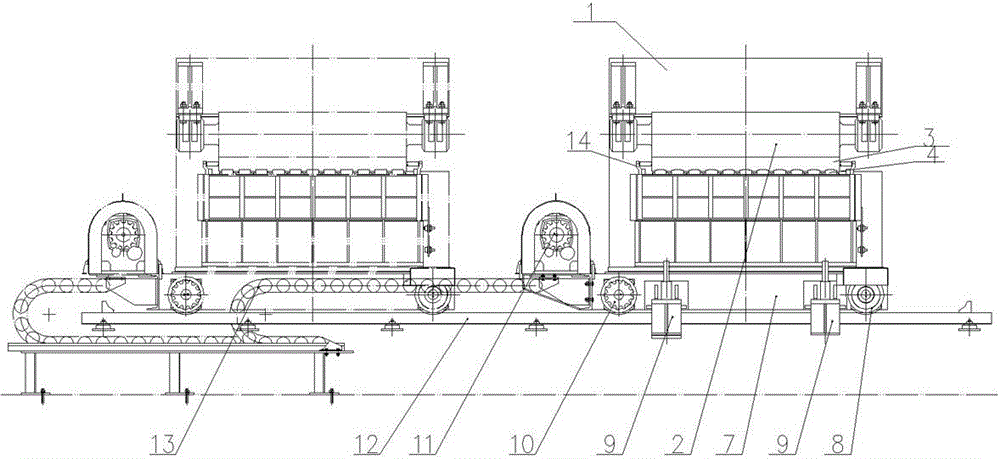

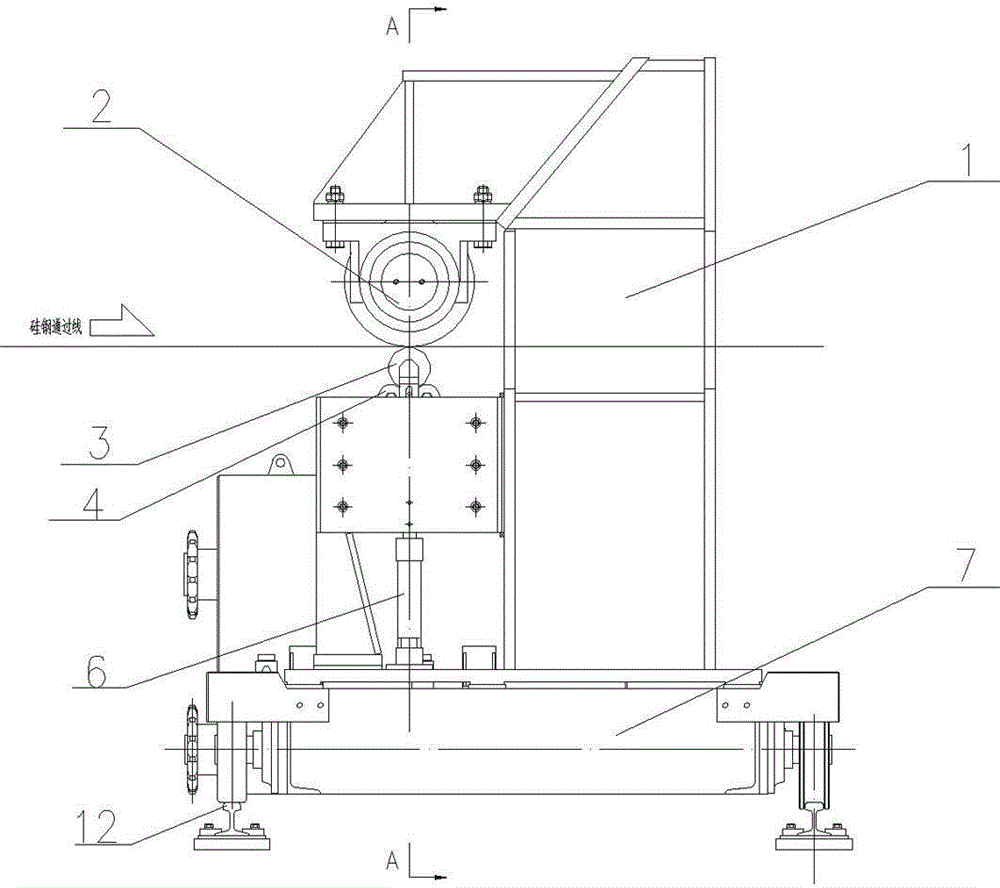

[0035] Such as Figure 1 to Figure 4 As shown, a silicon steel mechanical scoring machine includes a vehicle frame 7 that can move along the guide rail 12. The vehicle frame 7 is provided with a frame 1, and the frame 1 is provided with the same direction engraving roller 2, pressure roller 3 and The supporting roller 4 and the tooth-engraving roller 2 are fixed in position. The pressure roller 3 is located directly below the tooth-engraving roller 2 and can move up and down. The pressure roller 3 is supported by two rows of support rollers 4 below. Arranged in the direction and form a "product" shape with the pressure roller 3, two rows of support rollers 4 correspond to each other in the radial direction of the pressure roller 3 (in this embodiment, there are 11 pairs of support rollers 4, the logarithm of the support rollers 4 and the pressure roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com