Self-cleaning valve

A self-cleaning, valve technology, applied in valve devices, engine components, mechanical equipment, etc., can solve the problems of fluid pollution, easy accumulation of dirt and dirt, and achieve the effect of avoiding adhesion and novel and ingenious structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

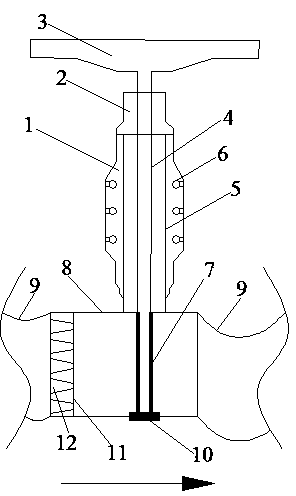

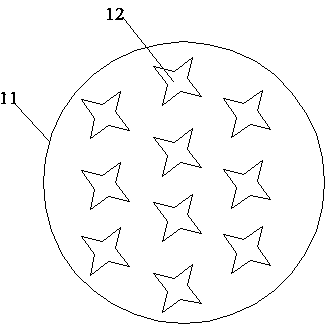

[0017] see figure 1 , a self-cleaning valve of the present invention, comprising: a valve body 2 with a valve cavity 1 formed inside, an adapter pipe fixedly connected to the valve body 2, a valve handle 3 and a valve stem 4 integrally formed with the valve handle 3 . Among them, the valve chamber 1 is provided with a central column 5 formed with an internal thread that cooperates with the valve stem 4, and an external thread is formed above the middle of the valve stem 4 (not shown in the figure), and the valve handle 3 drives the valve stem 4 to face each other. Rotate the central column 5 to switch between the open and closed states of the valve. Inevitably, a through hole for the valve rod 4 to extend is formed on the adapter pipe, and when the valve rod 4 is completely inserted into the through hole, it is in the position figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com