Low-impedance capacitive touch screen and manufacturing method thereof

A technology of capacitive touch screen and manufacturing method, which is applied in the direction of electrical digital data processing, instrumentation, input/output process of data processing, etc., can solve the problems of affecting touch sensitivity, high impedance of touch electrodes, and product performance not worth the loss, etc. Achieve the effect of low production fine requirements, simple process realization, and favorable product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

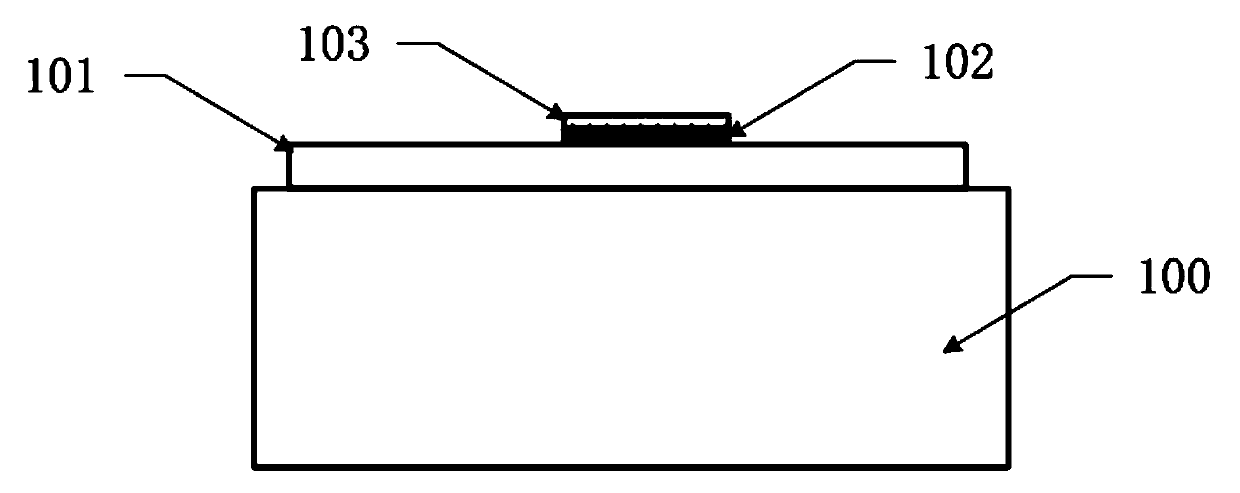

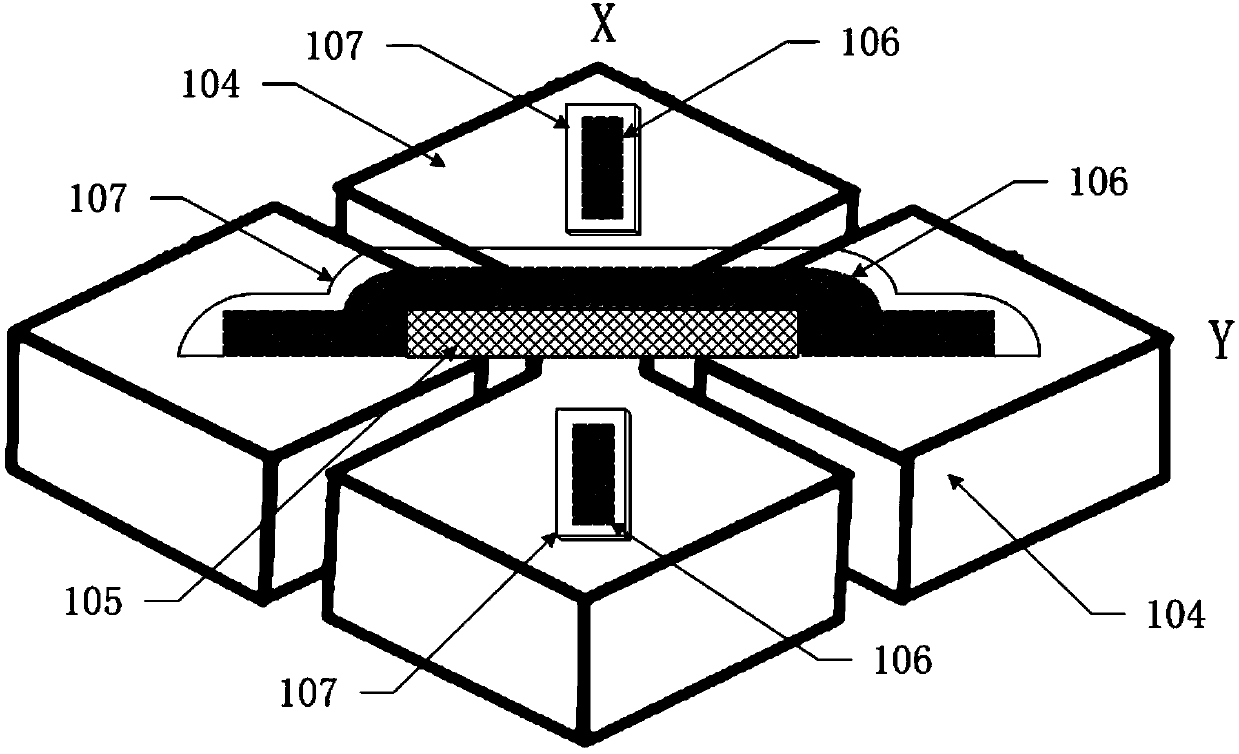

[0028] The present invention reduces the impedance of the touch electrode by combining the metal wire on the touch layer, thereby improving the touch sensitivity. The material of the metal wire can be metal, or non-metal with high electrical conductivity, such as carbon nanotubes, conductive polymers and the like.

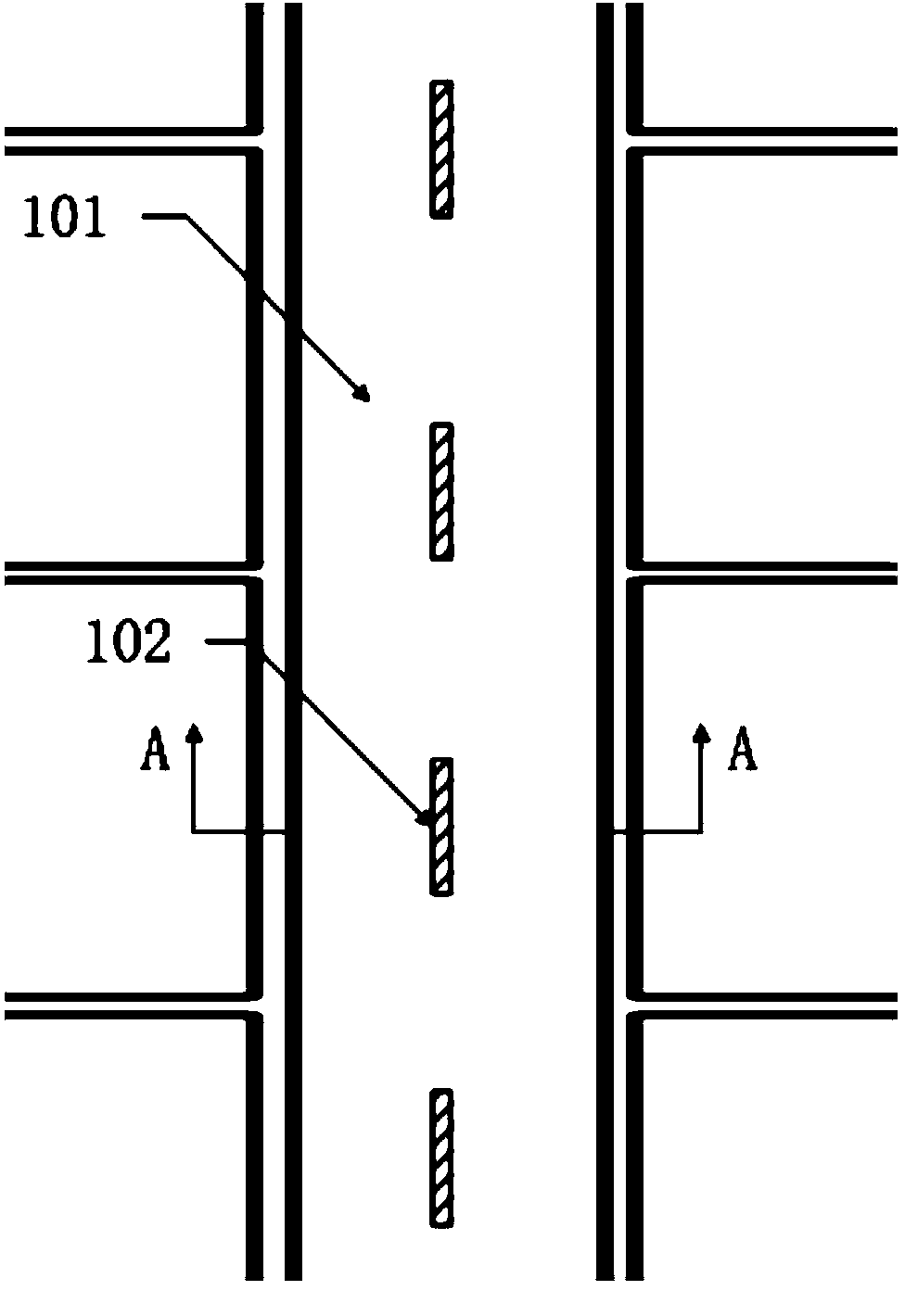

[0029] The shape and structure of the metal wire is not limited, and it may be a thin wire, a thick wire, an irregular curve or a closed curve of any shape, and the like. It is mainly arranged on the touch electrode, which has the greatest effect on improving the touch sensitivity. However, the arrangement of the metal wire is not limited to the touch electrode, it can also be used as a short-circuit connection between separated graphics in the touch graphics, that is, the two ends of the same metal wire are respectively lapped on different sides of each other. On the two touch layer materials that are in contact, the short circuit between the two is realized. Si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com