A built-in overcurrent and overheating protector

An over-current overheating and protector technology, applied in the direction of thermal switch components, etc., can solve the problems of narrow use range of thermal protector, large protection span of thermal protector, large heater resistance value, etc. The effect of reducing the protection span and widening the power range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

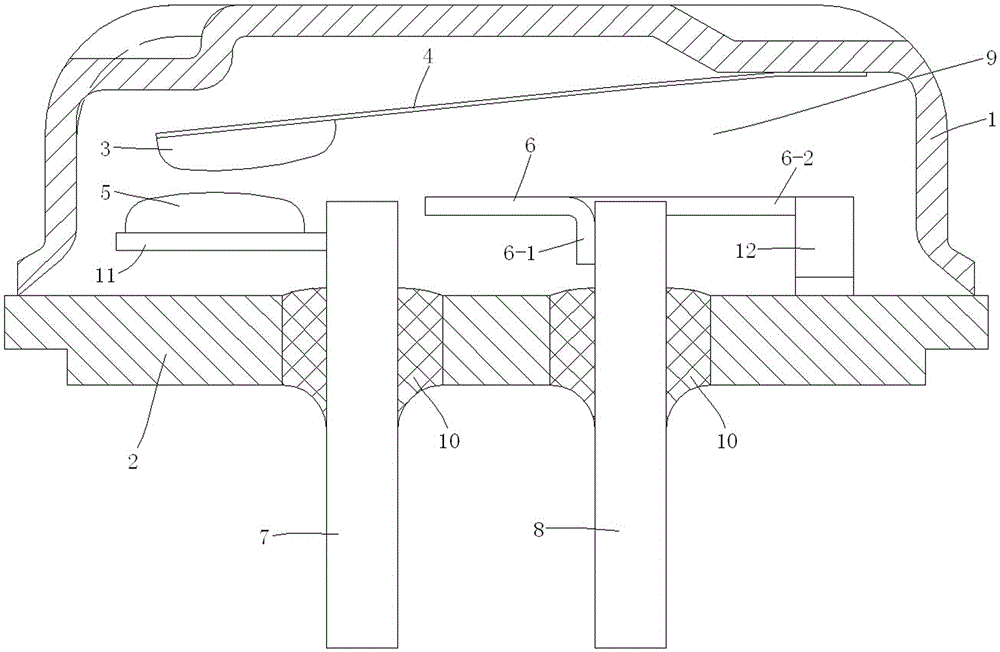

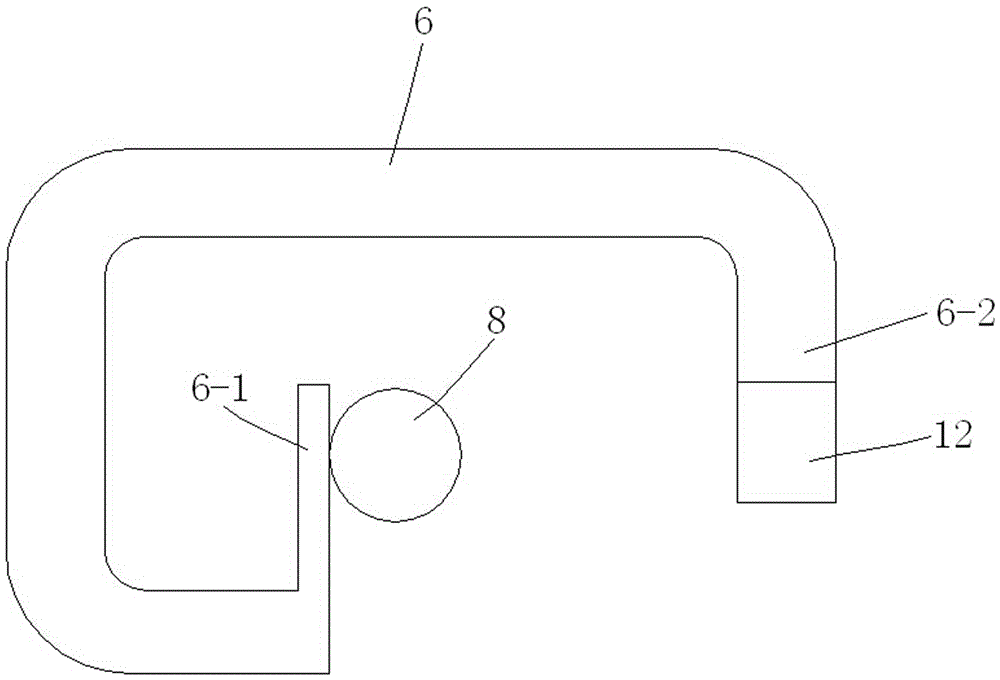

[0014] see figure 1 , 2 A built-in overcurrent and overheating protector is shown, which is used to cut off the current of the compressor or motor under overcurrent and overheating conditions. It includes a metal shell 1 with an open bottom, and the bottom opening of the shell 1 is closed by welding. The metal bottom plate 2 is provided with a moving contact 3 and a thermosensitive plate 4 that reverses when reaching the set temperature and resets when it is lower than the set temperature, a static contact 5 arranged corresponding to the moving contact 3, and a resistor Heating wire 6 and two terminals 7, 8; the upper ends of the two terminals 7, 8 respectively pass through the base plate 2 and extend into the closed space 9 formed by the shell 1 and the base plate 2, and the two terminals The shafts of 7 and 8 are respectively insulated and sealed with the bottom plate 2 through insulating glass 10, and the static contact 5 is fixedly installed on the upper end of one of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com