System for storage and transportation of spent fuel

A tank storage and storage tank technology, which is applied in the direction of portable protective containers, greenhouse gas reduction, climate sustainability, etc., to improve internal heat transfer and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

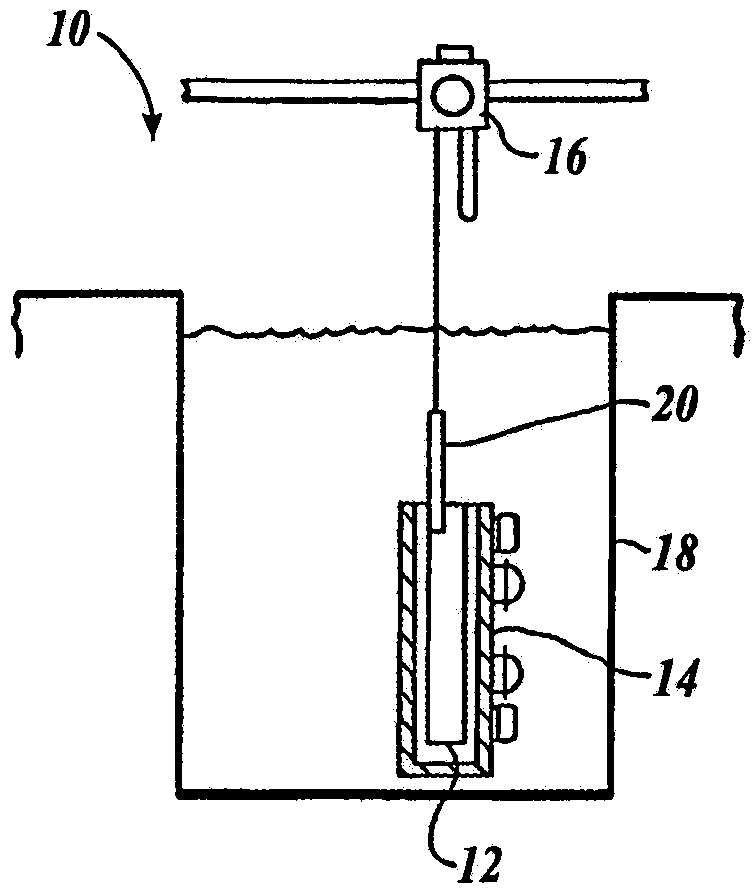

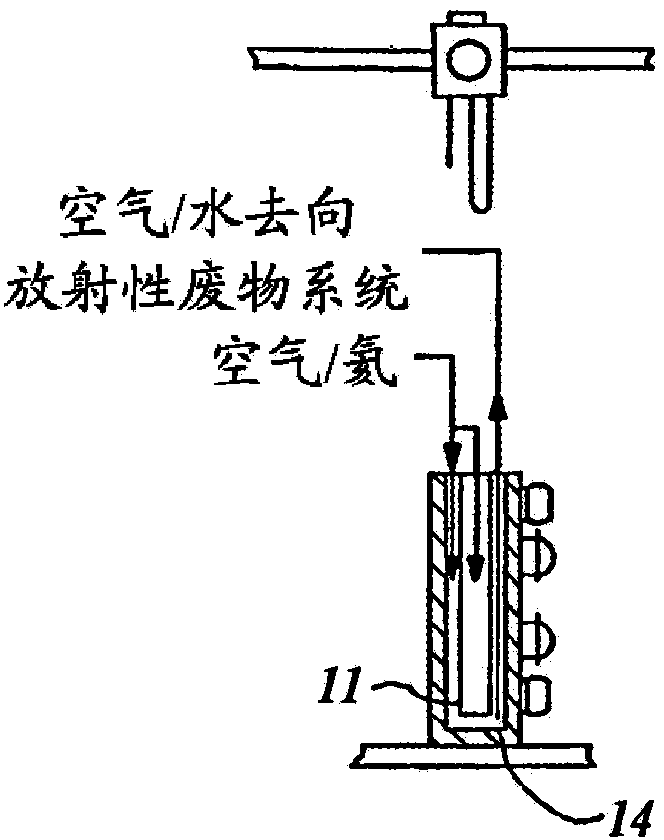

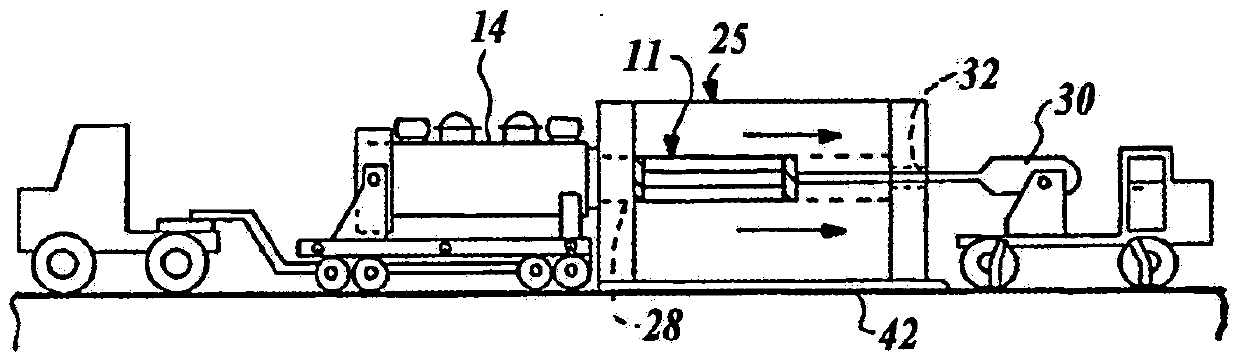

[0048] A horizontal modular dry irradiated fuel (spent fuel) storage system will first be described. Referring to Figures 1-4, a horizontal modular dry irradiated fuel storage system 10 is depicted in accordance with an embodiment of the present invention. Additionally, a process for storing irradiated fuel is described. As stated in more detail below, the systems and processes described herein are improvements over previous systems and processes (as seen in FIGS. 1-4 ) described in U.S. Patent No. 4,780,269, the disclosure of which The contents are expressly incorporated herein by reference.

[0049] Referring to Figure 1, system 10 utilizes a specially designed dry shielding tank assembly 12, which in Figure 5-10 shown in more detail in , as described in more detail below. Canister assembly 11 is inserted into transfer bucket 14 . The transfer bucket 14 and canister assembly 11 may be lowered by crane into a water-filled irradiated fuel storage pool 18 (see Figures 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com