Full-automatic chocolate pouring equipment and preparation method using same

A chocolate, fully automatic technology, applied in application, cocoa, food science and other directions, can solve the problems of difficult maintenance, low production efficiency, high maintenance cost, avoid microbial contamination, reduce equipment failure rate, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

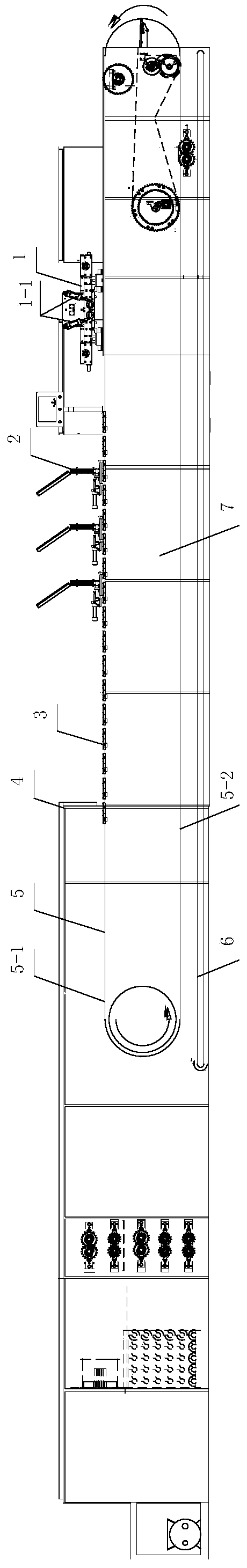

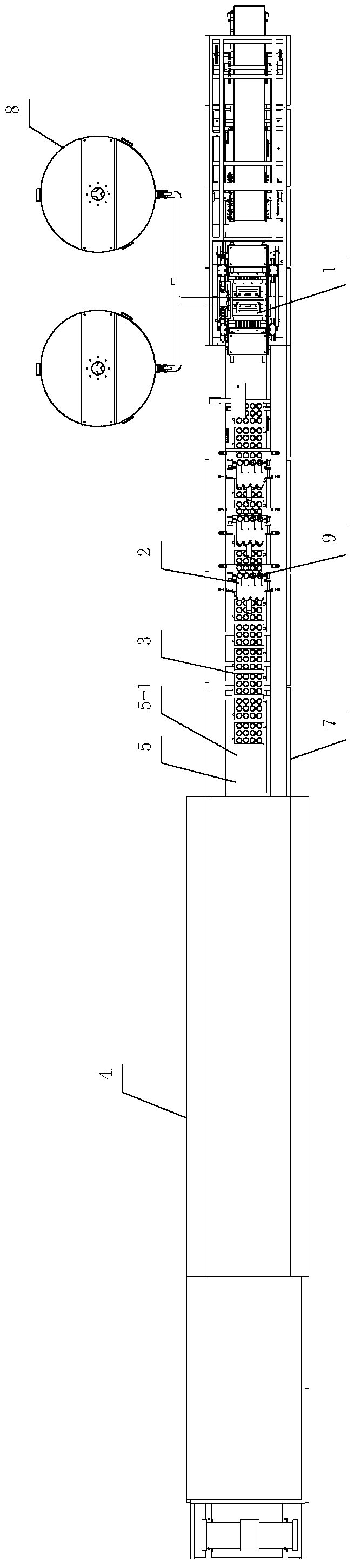

[0052] as attached figure 1 with 2 As shown, the full-automatic chocolate pouring equipment of the present embodiment comprises:

[0053] Equipment body 7 and refrigeration system 4.

[0054] It also includes a circular transport system 5 fixed on the equipment body 7, a part of the circular transport system 5 stretches into the inside of the refrigeration system 4, and the circular transport system 5 includes an upper conveyor belt 5-1 and a lower conveyor belt 5-2. The system is driven by a servo motor A.

[0055] It also includes a detachable mold 3 fixed on the circular transport system 5, the upper transport belt 5-1 can transport the mold 3 into the freezing system 4, the lower transport belt 5-2 can transport the mold away from the freezing system 4, and the lower transport belt Just below the 5-2 is provided with a collection conveyor belt 6, and the collection conveyor belt 6 is consistent with the movement direction of the lower conveyor belt 5-2.

[0056] It als...

Embodiment 2

[0060] This embodiment provides a method for making chocolate using the fully automatic chocolate pouring equipment described in Embodiment 1, comprising the following steps:

[0061] a. Inject the prepared chocolate solution into the feeding system 8, start the power supply of the equipment, driven by the servo motor A, the upper conveyor belt 5-1 carries the mold 3 and moves towards the freezing system 4;

[0062] b. Bake the mold 3 to remove the moisture attached to the surface of the mold 3. When the mold 3 passes directly under the pouring system, the servo motor B drives the pouring system 1 to move along the guide rail to the movement direction of the upper conveyor belt 5-1. The PLC controller controls the servo The running speed of the motors A and B is adjusted to keep the movement speed of the upper conveyor belt 5-1 consistent with that of the pouring system 1. The PLC controller controls the movement speed of the servo motor C so that the pouring head 1-1 is stably...

Embodiment 3

[0070] This embodiment provides a method for making a chocolate sandwich biscuit using the fully automatic chocolate pouring equipment described in Example 1, comprising the following steps:

[0071] a. Pour the prepared chocolate solution into the feeding system 8, turn on the power of the equipment, and the three cake placing devices 2 on the right side of the pouring system 1 arrange the biscuits into the mold 3 in advance, driven by the servo motor A, the upper conveyor belt 5 -1 carries the mold 3 and moves towards the refrigeration system 4;

[0072] b. Bake the mold 3 to remove the moisture attached to the surface of the mold 3. When the mold 3 passes directly under the pouring system, the servo motor B drives the pouring system 1 to move along the guide rail to the movement direction of the upper conveyor belt 5-1, and the PLC controller controls the The running speed of the servo motors A and B is adjusted to keep the movement speed of the upper conveyor belt 5-1 cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com