Tobacco leaf threshing and redrying and impurity winnowing processing technology and equipment

A technology of winnowing, impurity removal, and treatment process, which is applied in the fields of tobacco, tobacco preparation, application, etc., and can solve the problems affecting the use of tobacco leaves in cigarette enterprises, poor overall quality, and weather spots, etc., to improve smoking quality and purity, and produce The effect of increasing the film rate and improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

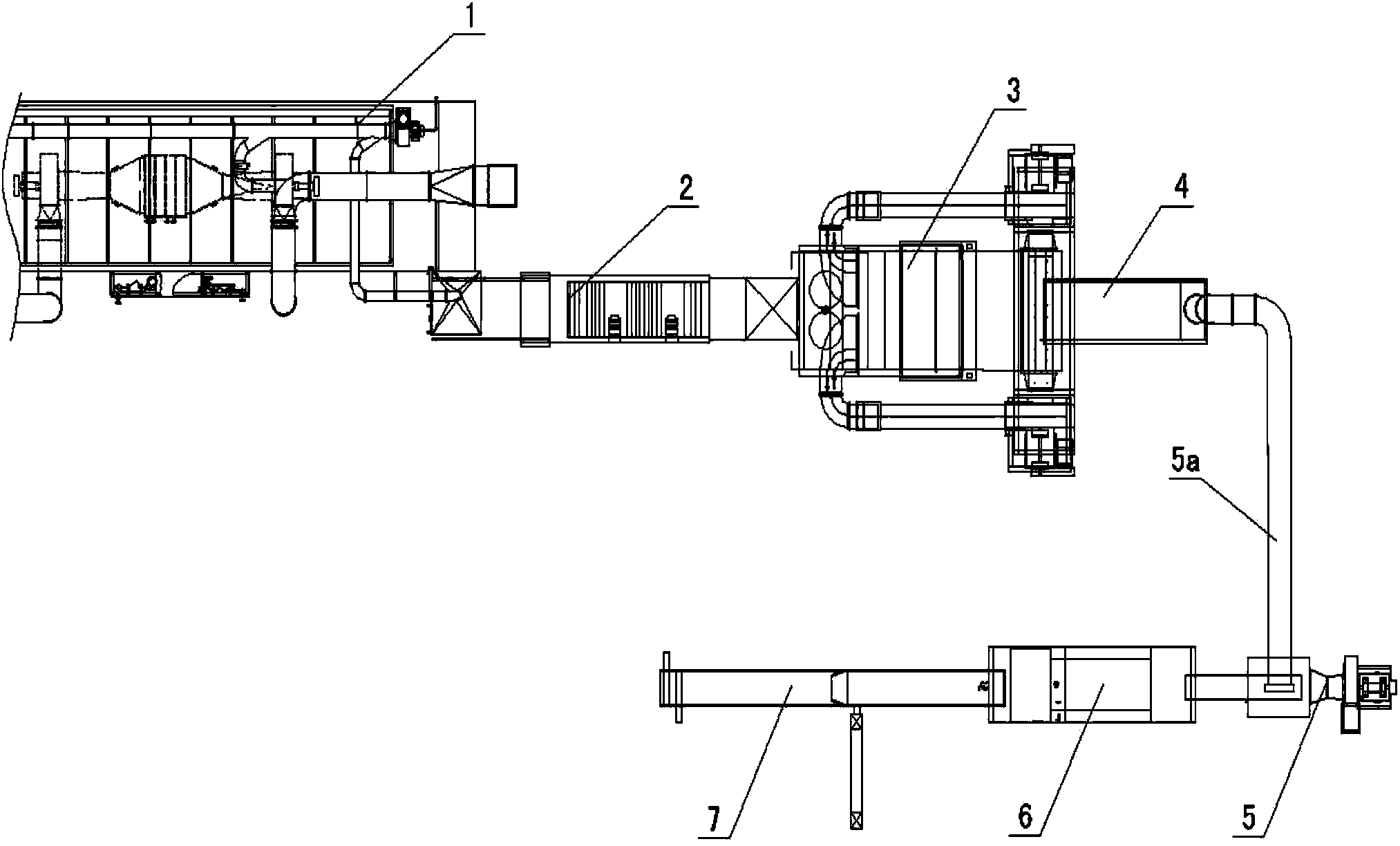

[0014] In this embodiment, the treatment process of threshing and re-roasting tobacco leaves by winnowing and removing impurities is to firstly carry out winnowing on the tobacco leaf raw materials after hot air moistening, and sort out the main tobacco leaf materials and tobacco leaf miscellaneous materials, and the main tobacco leaf materials are kept in the main tobacco leaf materials. On the production line, the separated tobacco leaf miscellaneous materials are manually removed, and the impurities removed are the tobacco leaf residues; it is characterized in that: the tobacco leaf residues are kept separated from the tobacco leaf main material, and the tobacco leaves are The residual material is conveyed to the chip drying unit, and the tobacco leaf residual material and the chip are subjected to drying, screening and packaging processes.

[0015] In specific implementation, the residual tobacco leaves are transported to the debris drying unit by means of wind blowing.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com