Air suction type bead stringing machine and operating method thereof

A bead threading machine and air-breathing technology, which is applied in jewelry, clothing, applications, etc., can solve the problems of reducing labor intensity, inability to work for a long time, and friction loss, so as to reduce labor intensity, reduce the probability of damage, and ensure smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

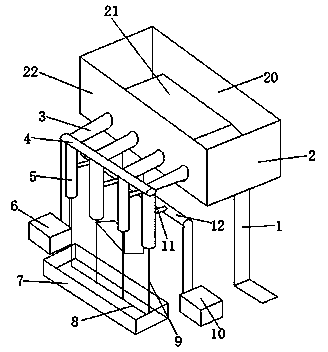

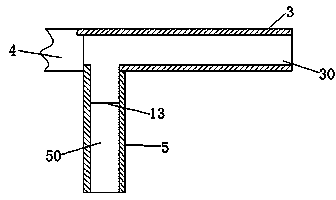

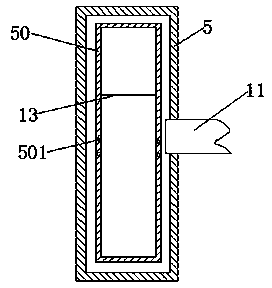

[0026] refer to Figure 1 to Figure 4 As shown, a suction bead threading machine includes a bracket 1, a hopper 2 arranged above the bracket 1, an external suction bead pipe 3 that runs through the hopper 2, and a first air pipe that communicates with the external suction bead pipe 3 4, and the outer bead drop tube 5 arranged below the first air pipe 4, and the bead threading rod 9 arranged below the outer bead drop pipe 5, and the fixing frame 8 arranged below the bead threading rod 9, and the fixing frame 8 The material receiving box 7 below, and the suction pump 6 that is arranged on the left side of the material receiving box 7 and is connected with the first air pipe 4; The second air pipe 12, and the blower fan 10 that is arranged on the right side of the material receiving box 7 and links to each other with the second air pipe 12, and the inner suction bead pipe 30 that is arranged in the outer bead suction pipe 3, and the inner bead pipe that is arranged on the outer b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com