Wire plate dust removal components and dust collectors

A silk board and component technology, applied in the direction of electrode structure, electrostatic separation, power supply technology, etc., can solve the problem of high corona inception voltage, achieve the effect of reducing corona inception voltage and electric field energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It should be noted that the embodiments in the application and the features in the embodiments can be combined with each other if there is no conflict. Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

[0030] The embodiment of the present invention provides a wire-board type dust removal component. The following is a specific introduction to the wire-board type dust removal component provided by the embodiment of the present invention:

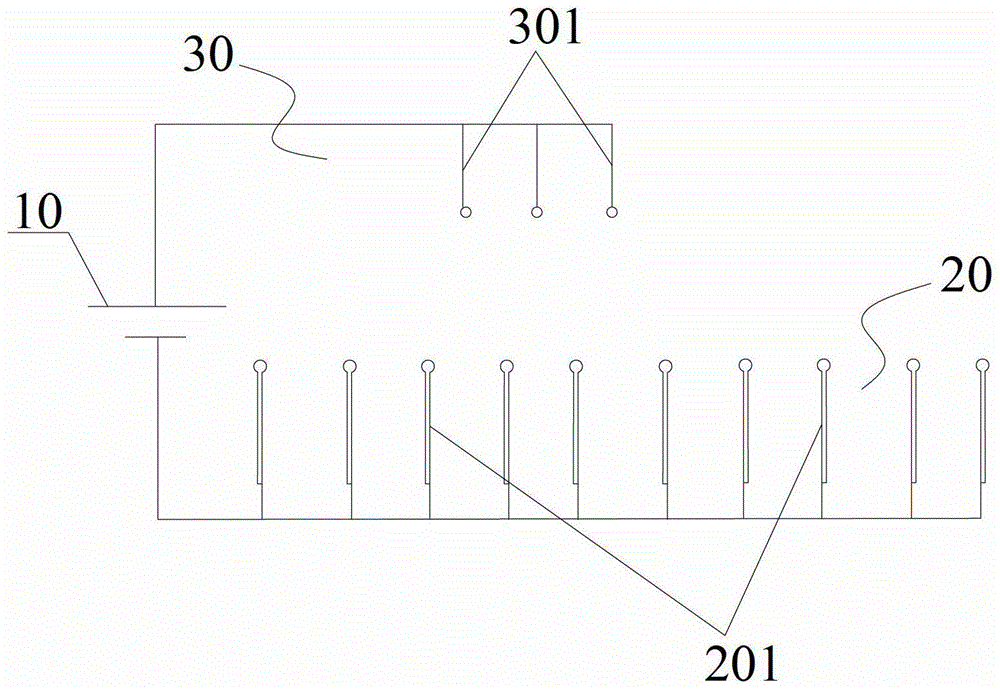

[0031] figure 1 It is a schematic diagram of a wire-plate dust removal component according to an embodiment of the present invention, such as figure 1 As shown, the wire-plate dust removal component of this embodiment includes: a power source 10, a dust collecting electrode 20, and a corona electrode 30. Specifically, the dust collecting electrode 20 is connected to the negative electrode of the power source 10 and has m dust collecting plates 201 arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com