Device and method for purifying molten steel in tundishes

A purification device and tundish technology, which is applied in the field of steelmaking and continuous casting, can solve the problems of inability to achieve purification effect, decline in the removal effect of inclusions, high power, etc., so as to avoid quality defects, avoid erosion and erosion, and improve the effect and efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

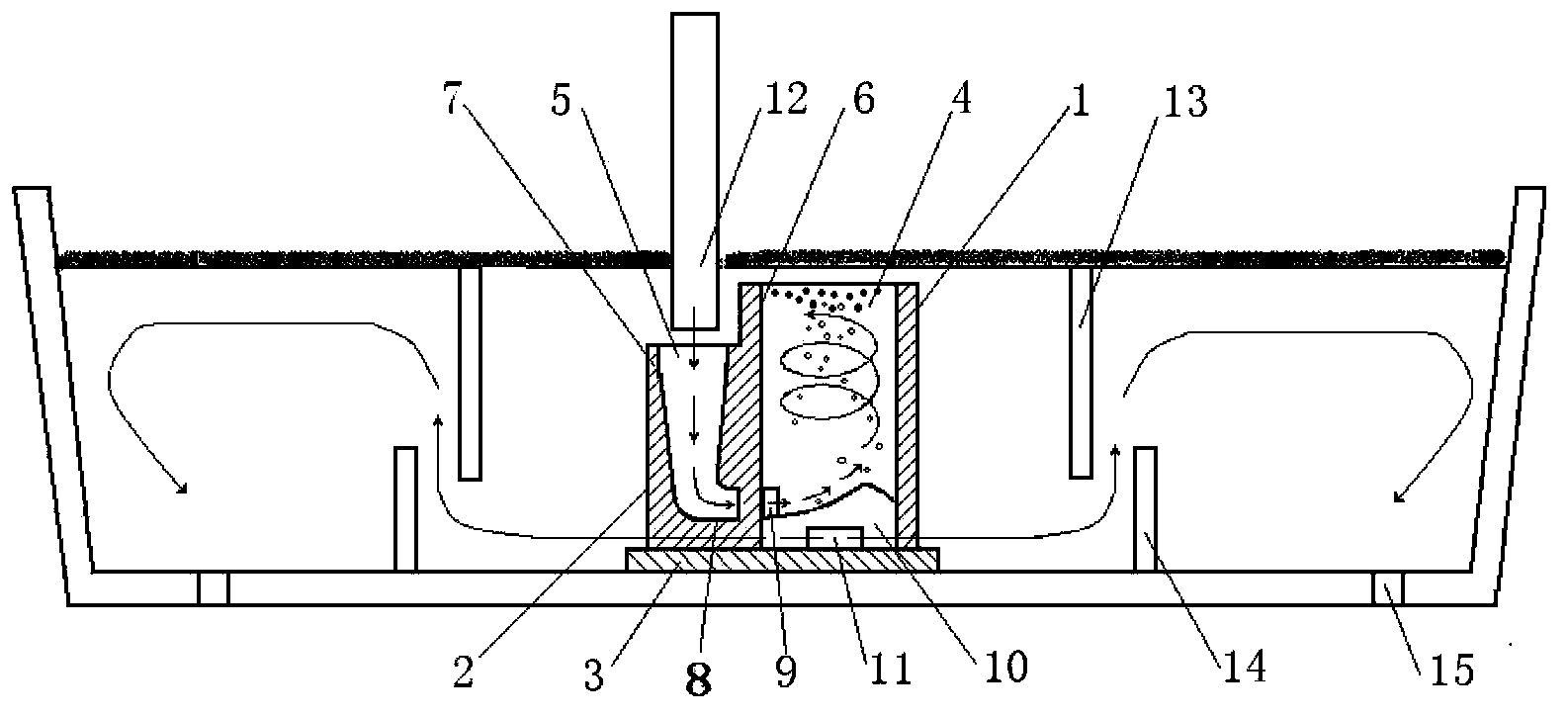

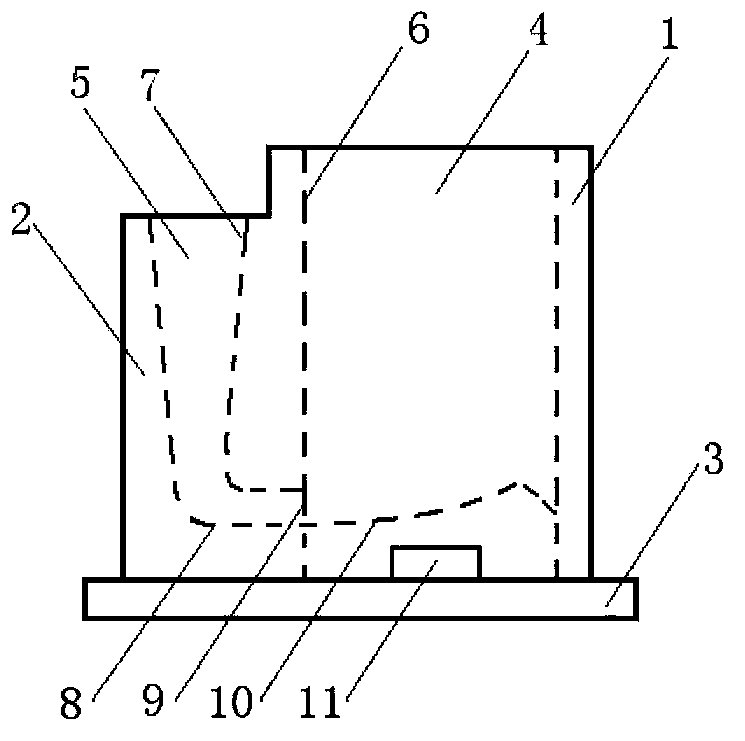

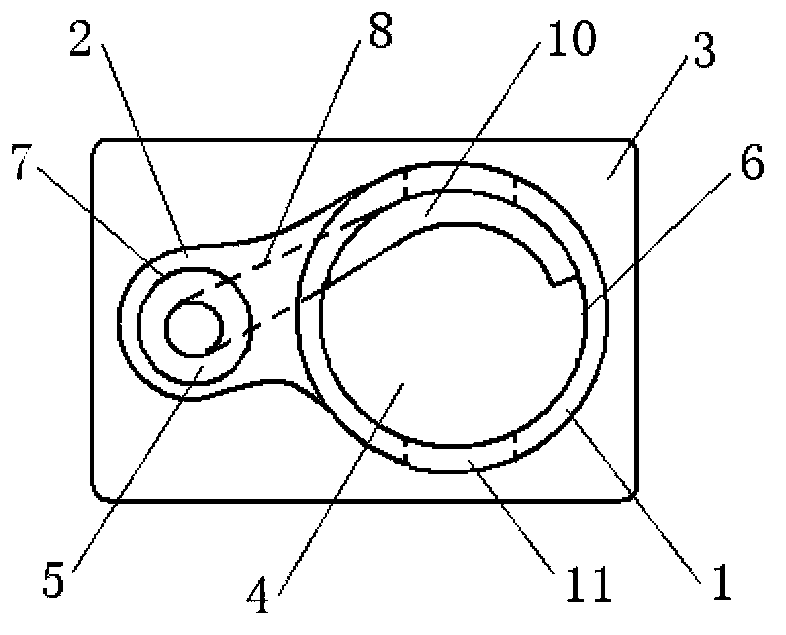

[0023] see figure 1 , figure 2 and image 3 , The method for purifying molten steel in the tundish is: place the drainage part of the purifying device under the ladle nozzle 12 and between two retaining walls 13 . The molten steel flows out from the ladle nozzle 12, and the strong impact kinetic energy of the ladle flow is used to convert the vertical impact flow into a horizontal tangential flow in the drainage chamber 5, and spray from the tangential nozzle 9 along the side wall 7 of the drainage chamber. out, rushes obliquely upwards into the swirl chamber 4 through the sliding jump board 10, drives the molten steel in the swirl chamber 4 to perform an axisymmetric rotational movement, and then utilizes centrifugal force to drive the non-metallic inclusions in the swirl chamber to gather toward the center of rotation, The concentration of inclusions in the center of rotation is significantly increased, thereby promoting the collision aggregation and growth of inclusions,...

Embodiment 2

[0026] The method for purifying the molten steel in the tundish is as follows: the drainage part of the purifying device is placed under the nozzle 12 of the ladle and between two retaining walls 13 . The molten steel flows out from the ladle nozzle 12, and the strong impact kinetic energy of the ladle flow is used to convert the vertical impact flow into a horizontal tangential flow in the drainage chamber 5, and spray from the tangential nozzle 9 along the side wall 7 of the drainage chamber. out, rushes obliquely upwards into the swirl chamber 4 through the sliding jump board 10, drives the molten steel in the swirl chamber 4 to perform an axisymmetric rotational movement, and then utilizes centrifugal force to drive the non-metallic inclusions in the swirl chamber to gather toward the center of rotation, The concentration of inclusions in the center of rotation is significantly increased, thereby promoting the collision aggregation and growth of inclusions, and quickly floa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com