Motor shaft bearing guard coreless mill processing device

A motor shaft and bearing technology, used in metal processing equipment, grinding/polishing equipment, grinders, etc., can solve the problem of not being able to meet the needs of large-scale, large-scale production of motor shafts, affecting the physical and mental health and personal safety of operators, Unfavorable product quality stability and other issues, to achieve the effect of beneficial to the health of operators, stable and reliable quality, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

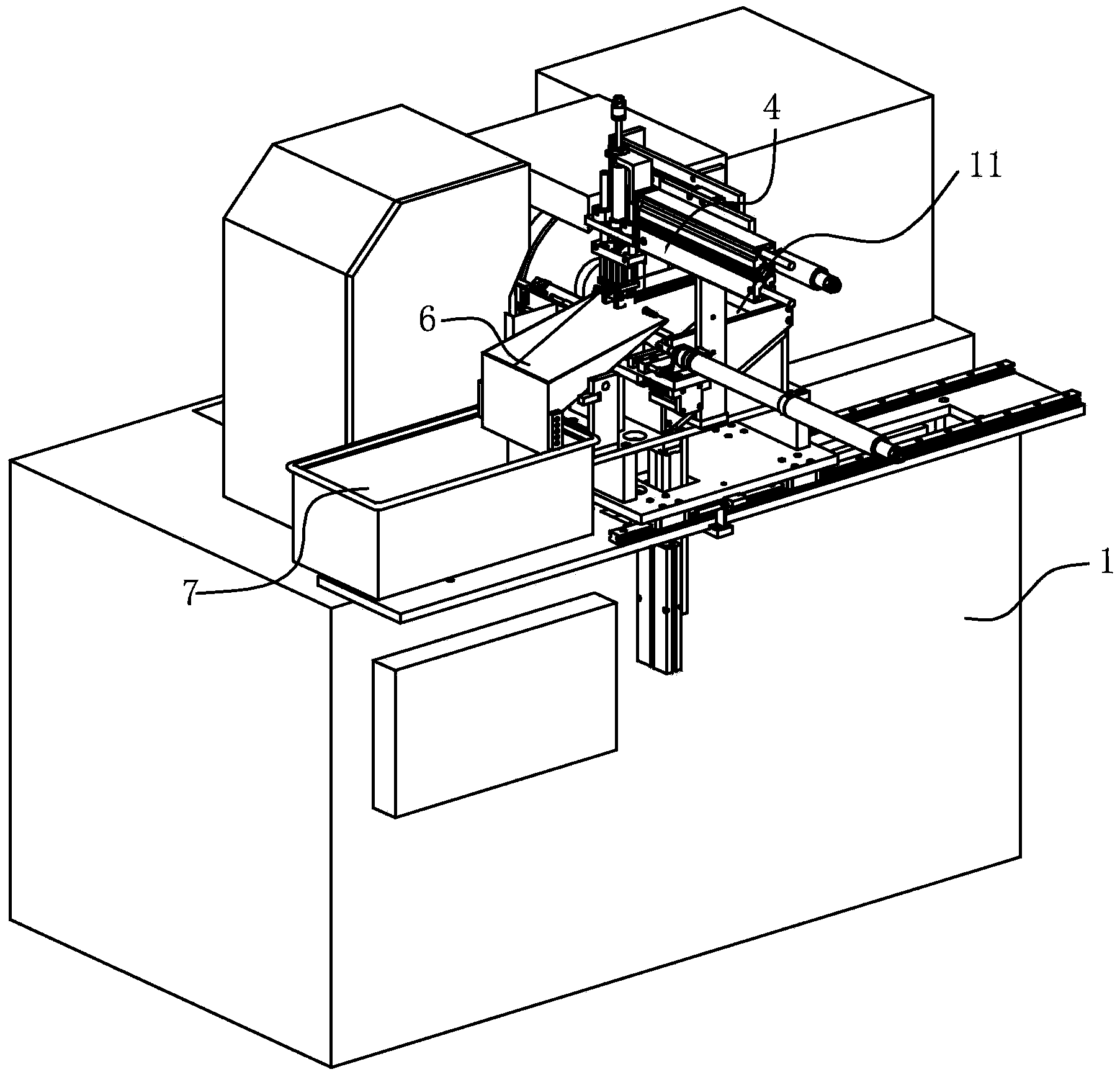

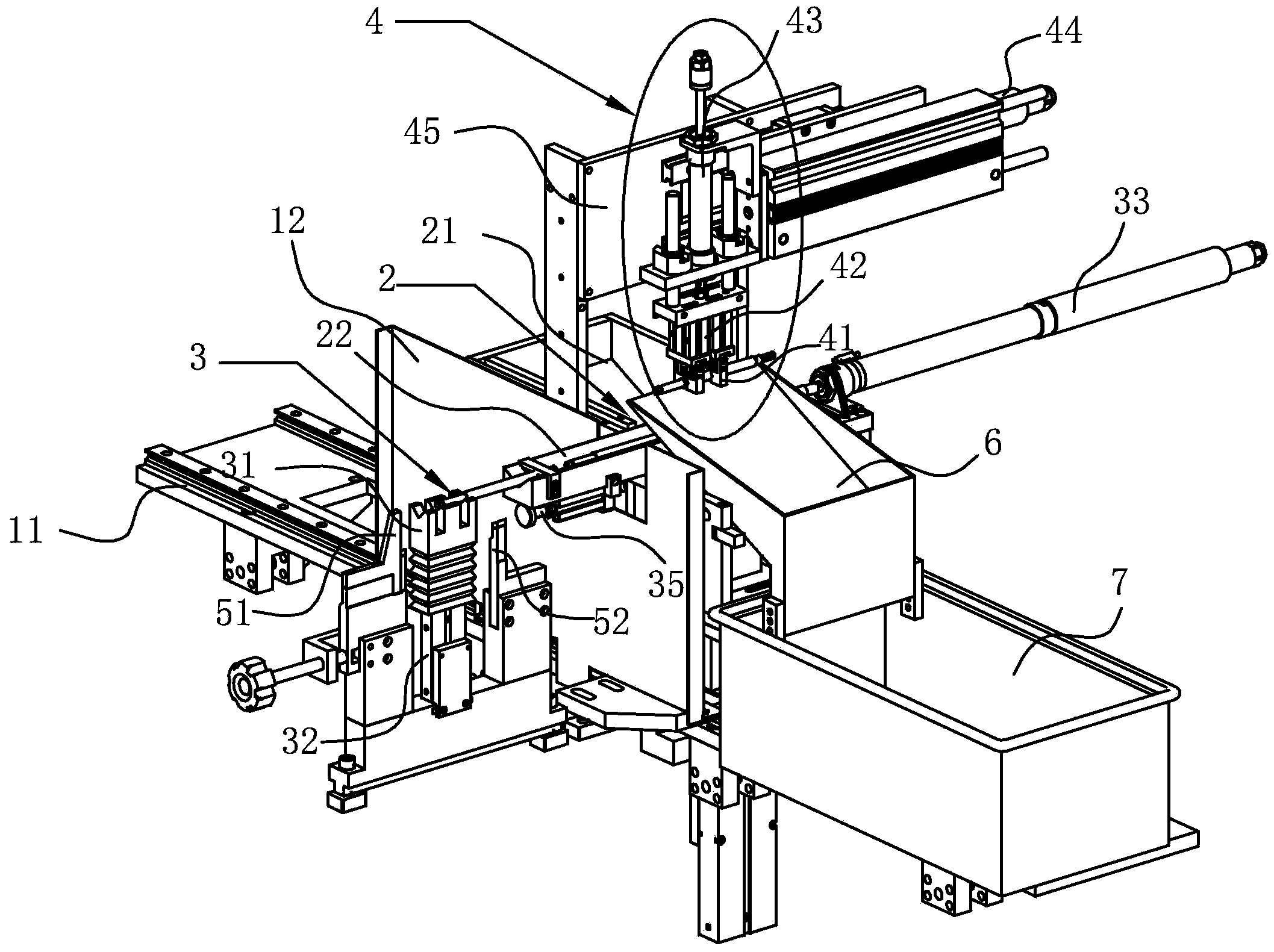

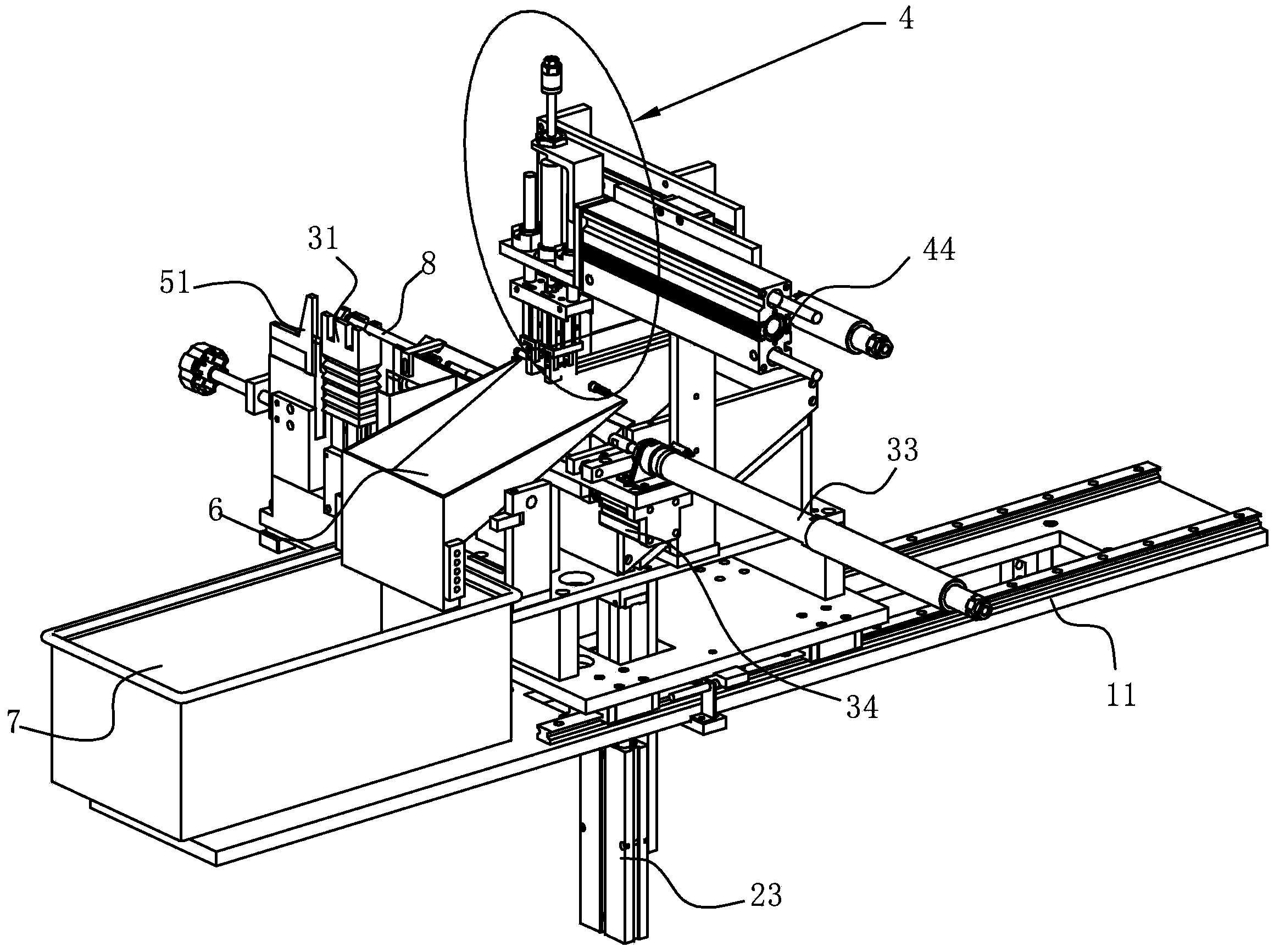

[0034] Such as figure 1 , 2 , 3, a coreless grinding processing equipment for motor shaft bearings, including a base 1, the base 1 is provided with an automatic feeding mechanism 2, a conveying mechanism 3, a grinding mechanism, an automatic discharging mechanism 4 and Program control system; the base 1 includes a strip bottom plate 11 and a fixed side plate 12 vertically arranged on the left side of the strip bottom plate 11; the automatic feeding mechanism 2 includes a hopper 21, a straight-line feeding V-shaped groove 22 and a top material Cylinder 23, hopper 21 is erected on the middle rear position of strip base plate 11 by a mounting plate 24, is provided with on the fixed side plate 12 and is provided with the opening that passes for described straight-line feed V-shaped groove 21, and described straight-line feed V-shaped groove 21 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com