Heat-insulation and compression-resisting plate

A technology of anti-pressure plate and heat insulation, which is applied in heat exchange equipment, pipeline protection through heat insulation, heat preservation, etc., can solve the problems of insufficient pressure resistance, short service life, poor heat insulation effect, etc., and achieves the advantages of convenient installation and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

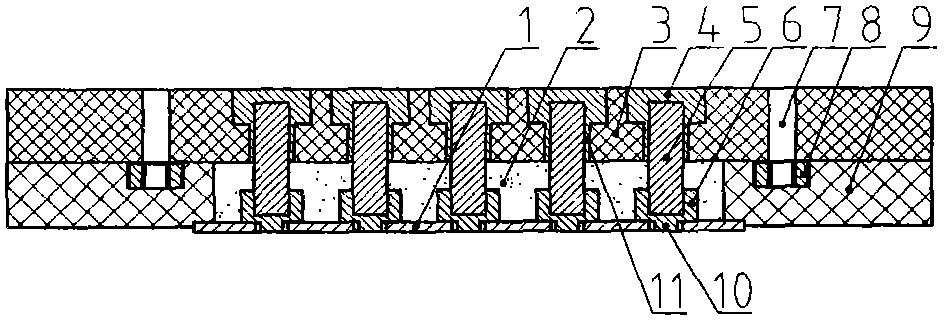

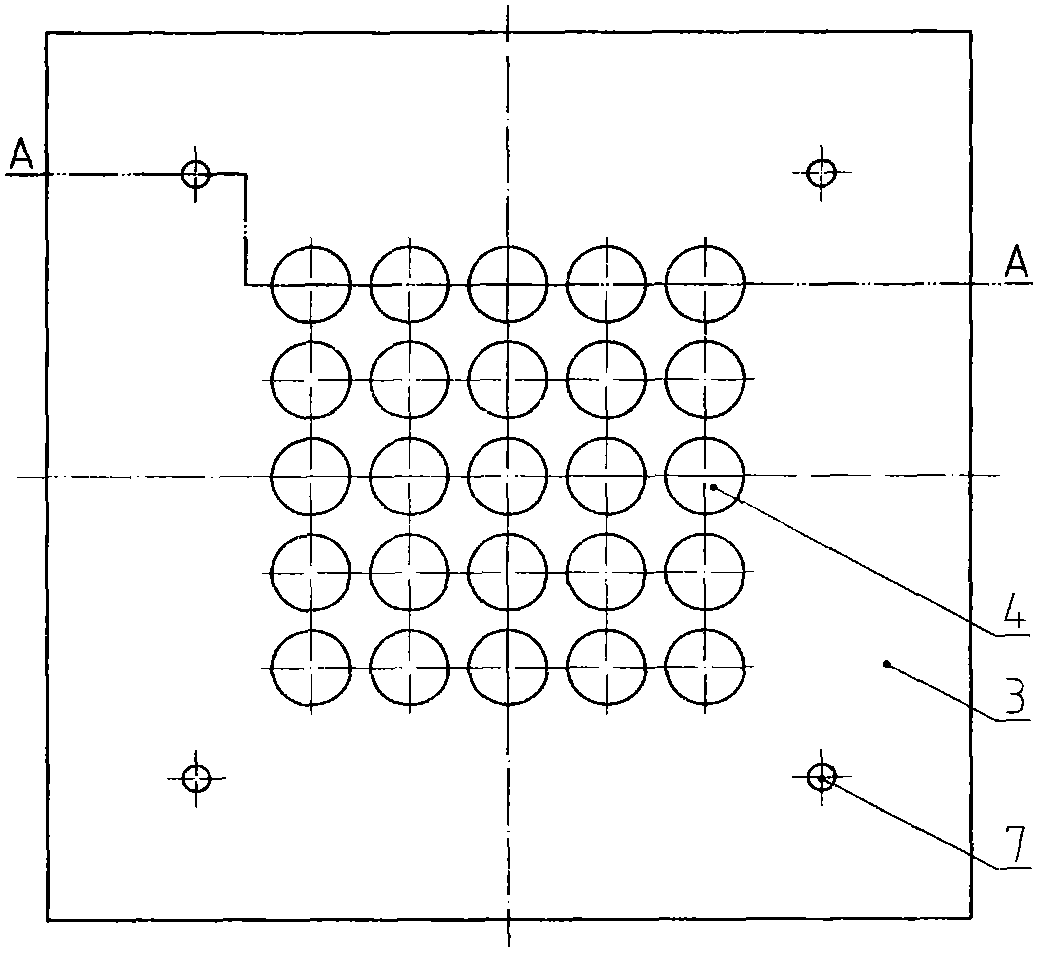

[0009] Embodiment 1 refers to appended Figure 1-2 It can be seen that it includes a frame 9, the upper anti-compression plate 3 is installed on the upper plane of the frame body 9, the lower anti-compression plate 1 is installed on the lower plane of the frame body 9, and the upper anti-compression plate 3 and the lower anti-compression plate 1 One to nine glass columns 5 for support are laid out per square decimeter between them, a thermal insulation layer 2 is provided in the remaining space, and a threaded hole 10 is provided on the lower anti-pressure plate 1, and a seat cushion 6 is installed in the threaded hole 10, and the glass column One end of 5 is inserted on the cushion 6, and the other end of the glass column 5 is inserted into the hole 11 of the upper compression plate. The upper part of the hole 11 of the upper compression plate is provided with a gland 4, and the upper anti-pressure plate 3 is provided with a mounting hole 7, and the bottom of the mounting hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com